Experiment model structure related to adhering feature between concrete and steel pile casting

An experimental model, the technology of steel casing, applied in the direction of measuring devices, instruments, mechanical devices, etc., to achieve the effect of uniform force and reduce test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

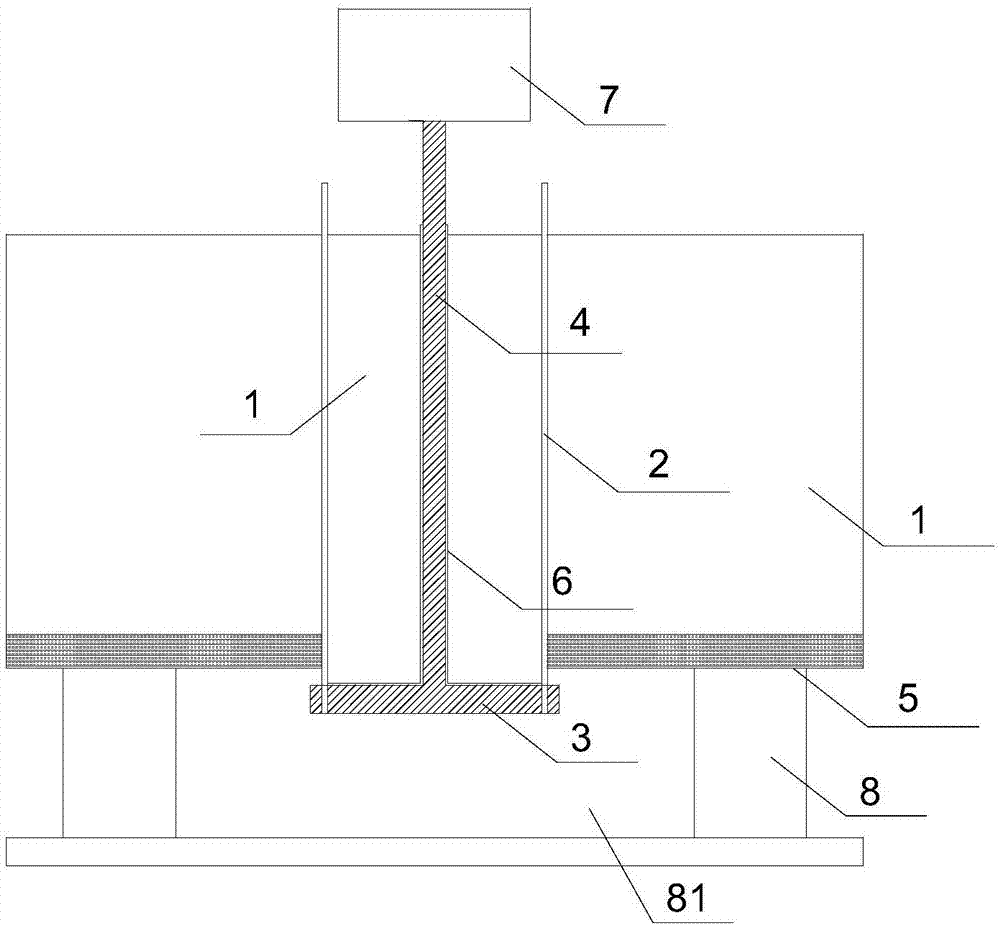

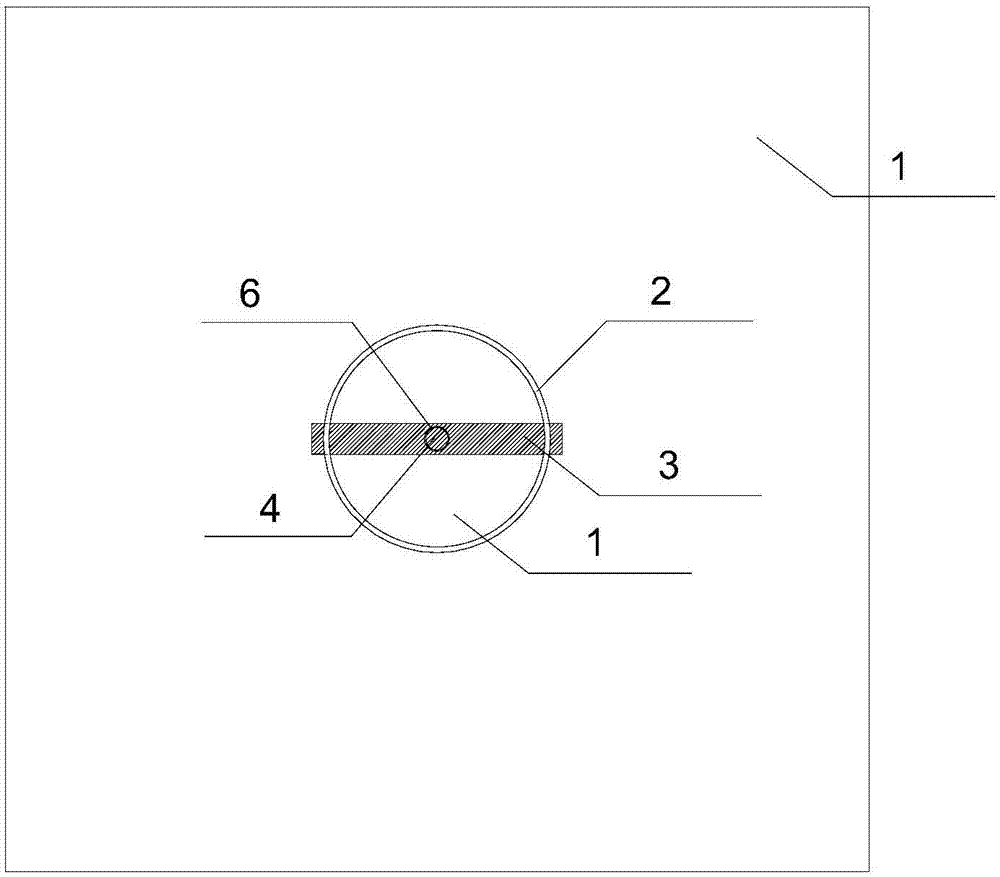

[0034] Such as Figure 1-2 As shown, an experimental model structure about the bonding characteristics of concrete and steel casing, including steel casing 2, loading module, reinforcement plate 5, said loading module includes beam 3 and loading column 4, and said steel casing 2 Concrete 1 is poured inside and outside respectively, and the loading module is connected with the steel casing (2), and the loading module provides the force to stretch the steel casing 2 to separate the steel casing 2 from the concrete 1. The steel casing 2 is provided with a hole, the beam 3 passes through the hole on the steel casing 2 and is fixed on the steel casing 2 , and one end of the loading column 4 is connected to the beam 3 .

[0035] In this embodiment, the level of the beam 3 on the steel casing 2 is lower than the level of the lower surface of the concrete 1 , and the other end of the steel casing 2 is higher than the level of the upper surface of the concrete 1 . The reinforcing plat...

Embodiment 2

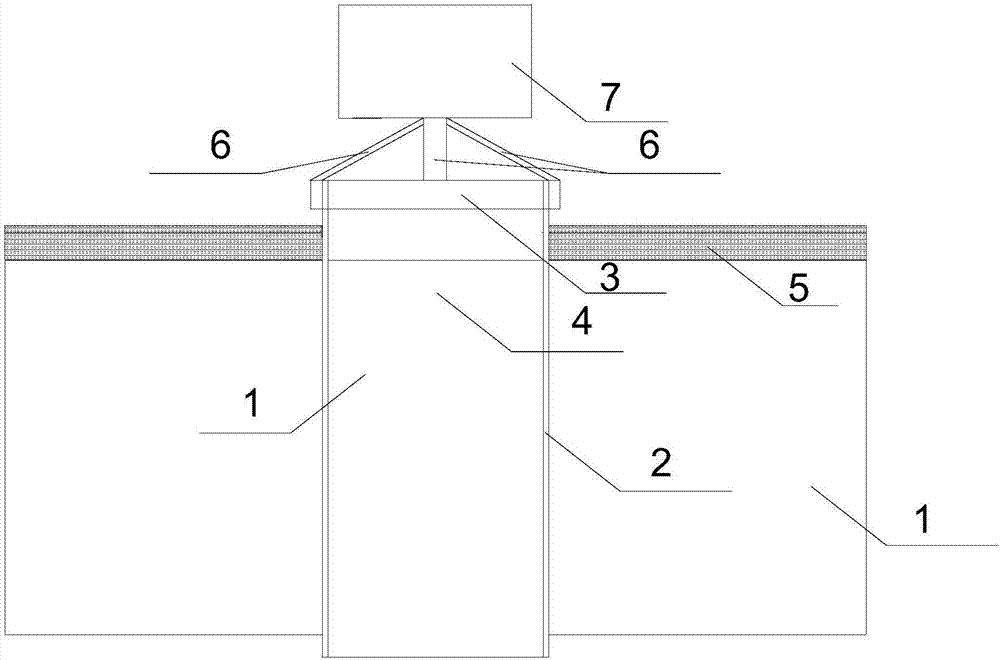

[0042] Such as Figure 3-4 As shown, an experimental model structure about the bonding characteristics of concrete and steel casings includes steel casings 2, beams 3, loading columns 4, and reinforcement plates 5, and the inner and outer walls of the steel casing 2 are respectively Concrete 1 is poured, and the side wall of the lower part of the steel casing 2 is provided with a hole through which the beam 3 passes. One end of the loading column 4 is fixed on the cross bar, and the other end is loaded with the tensile steel casing 2 to make it detached The force of the concrete 1, both ends of the steel casing 2 are located outside the concrete 1, and the beam 3 on the steel casing 2 is also located outside the concrete 1.

[0043]In this embodiment, the horizontal height of the beam 3 is higher than that of the concrete 1, and the reinforcing plate 5 is provided with a through hole through which the steel casing 2 passes, and the reinforcing plate 5 is arranged on the concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com