A car dent repair tool

A tool and automobile technology, applied in the field of automobile dent repair tools, can solve the problems of long time, high replacement cost, and inability to adjust the distance between two legs, etc., and achieve the effect of simple operation and low installation position requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

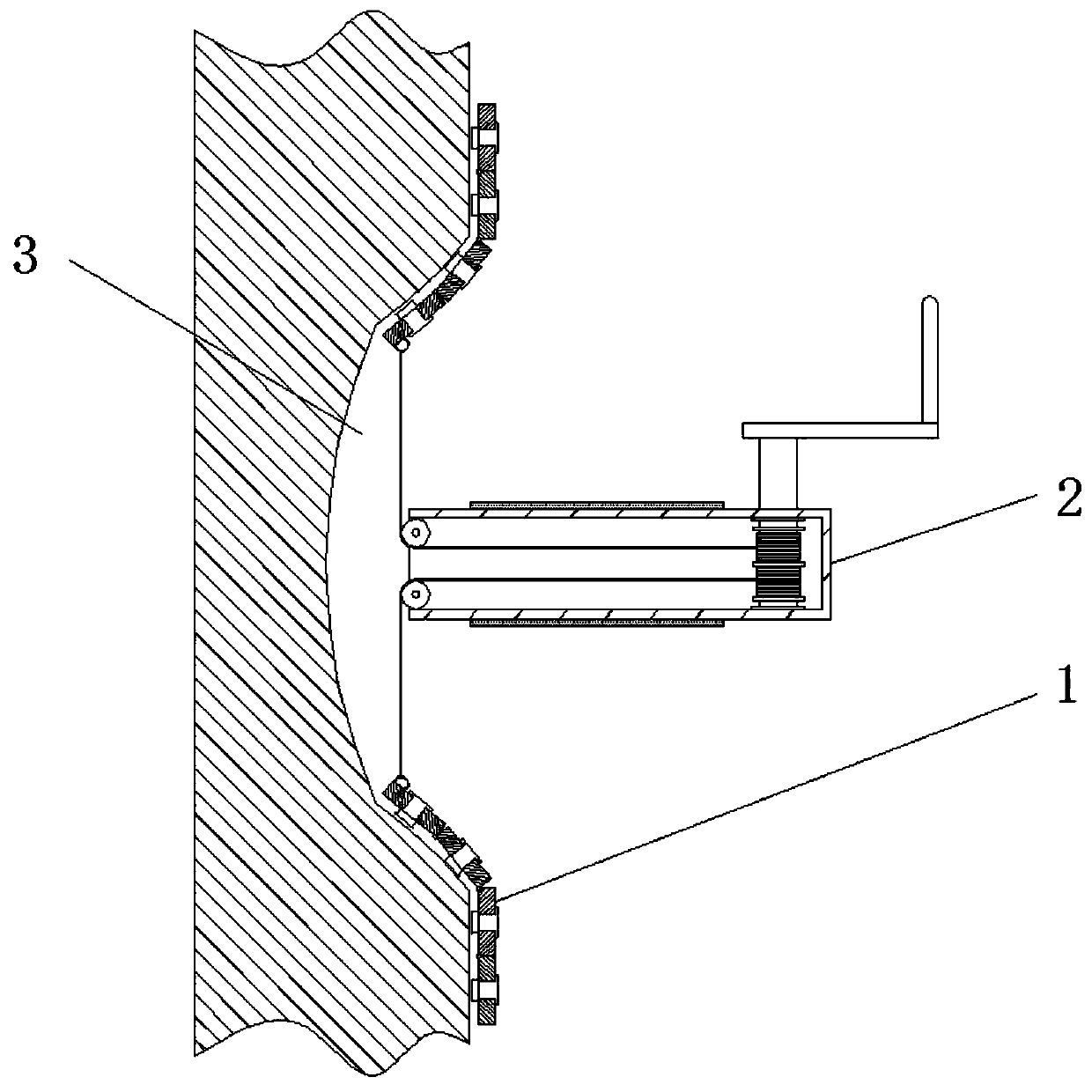

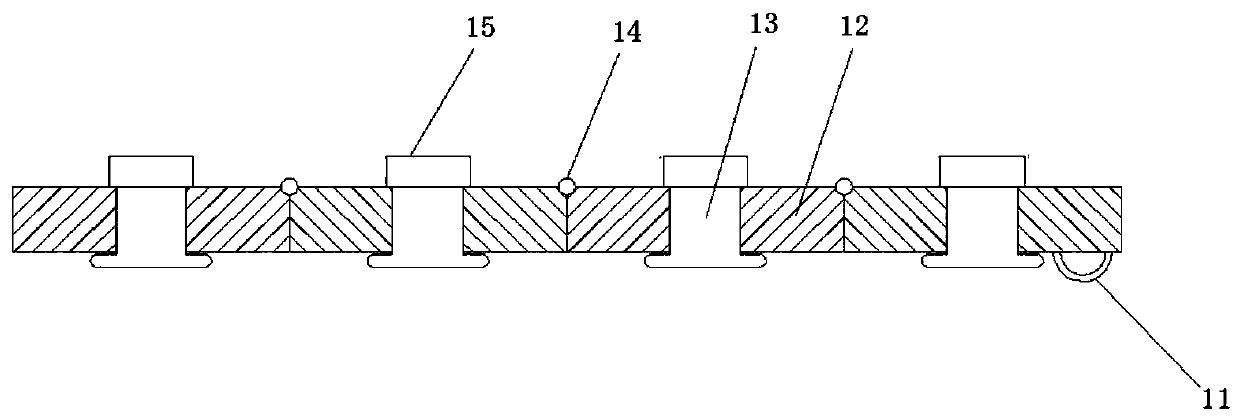

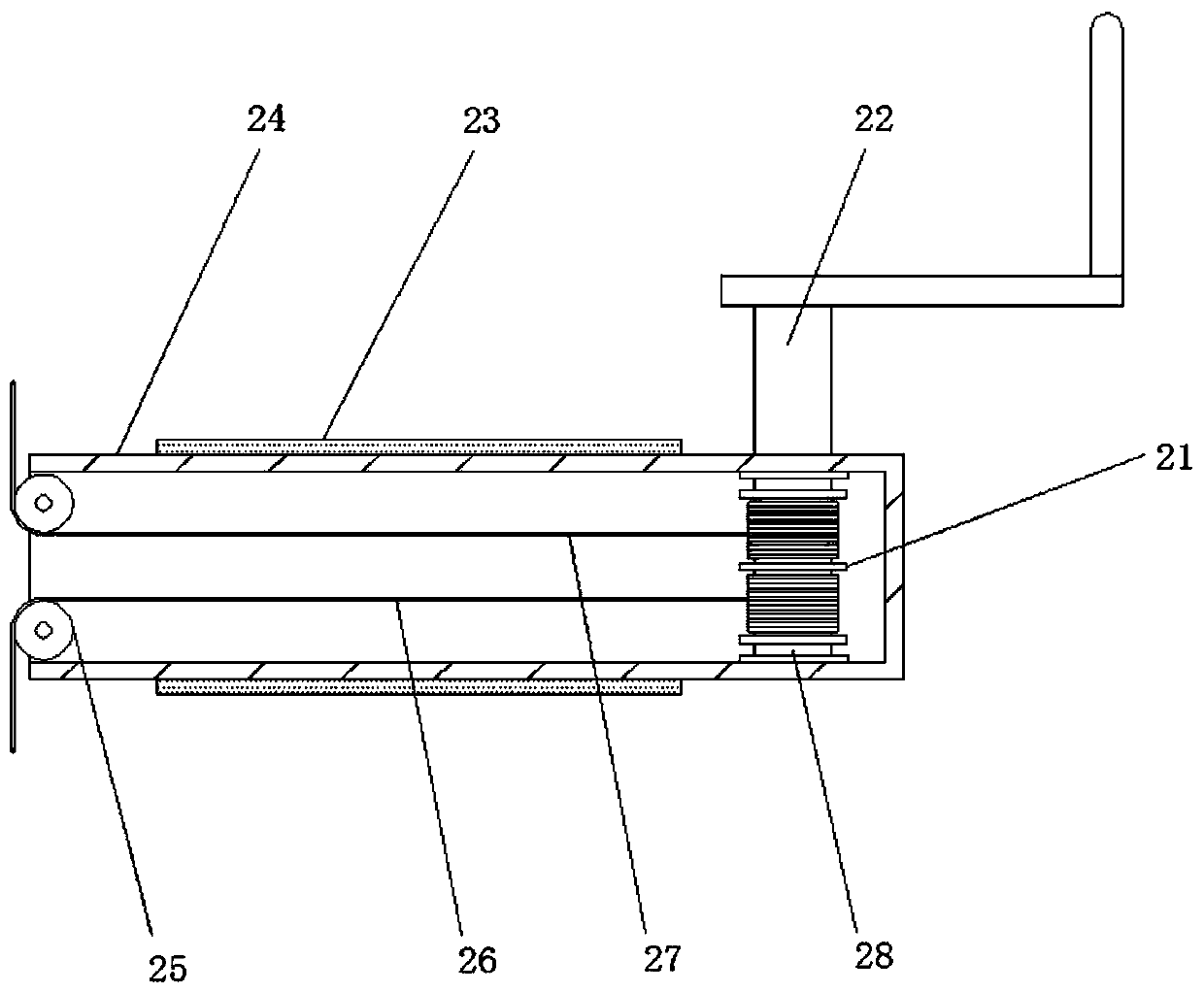

[0024] Such as Figure 1-3 The vehicle dent repairing tool shown includes a tension member 2 and a pair of adsorption chains 1. The adsorption chain 1 is formed by hinged with four rectangular hinge blocks 12. There is a hinge point 14 for the adjacent rectangular hinge block 12 to be hinged, a hook 11 is provided on the rectangular hinge block 12 at one end of the adsorption chain 1 away from the hinge point 14, and a T is provided through the rectangular hinge block 12 along the width direction. Type fixed rod 13, and T-shaped fixed rod 13 is provided with sucker 15 near one end of hinge point, and tension member 2 comprises cylinder 24, guide wheel 25, rotating shaft 28, rotating handle 22, dividing plate 21, connecting rope two 26 and Connect the rope one 27, the outside of the cylinder 24 is provided with a protective pad, one end of the cylinder 24 is provided with an opening, the outside of the cylinder 24 is provided with a protection pad and the inside of the cylinder...

Embodiment 2

[0027] A car dent repair tool, comprising a tension member 2 and a pair of adsorption chains 1, the adsorption chain 1 is formed by hinged with four rectangular hinge blocks 12, and the opposite sides of the rectangular hinge blocks 12 are arranged along the sides and bottoms in the same direction. A hinge point 14 for adjacent rectangular hinged blocks 12 to be hinged, a hook 11 is provided on the rectangular hinged block 12 at one end of the adsorption chain 1 away from the hinged point 14, and a T-shaped fixing is provided throughout the rectangular hinged block 12 along the width direction. Rod 13, and one end of T-shaped fixed rod 13 is provided with rubber pad near hinge point 14, and tension member 2 comprises cylindrical tube 24, guide wheel 25, rotating shaft 28, rotating handle 22, dividing plate 21, connecting rope two 26 and connecting Rope one 27, the outer side of cylindrical tube 24 is provided with protective pad, and one end of cylindrical tube 24 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com