Ship rotating shaft system phase angle measuring device and method

A technology for measuring devices and phase angles, applied to measuring devices, devices using electric devices, devices using electric/magnetic methods, etc., can solve problems such as harsh environments, cumbersome steps, dust, and oil pollution, and achieve low requirements for installation locations , Easy installation and maintenance, good anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

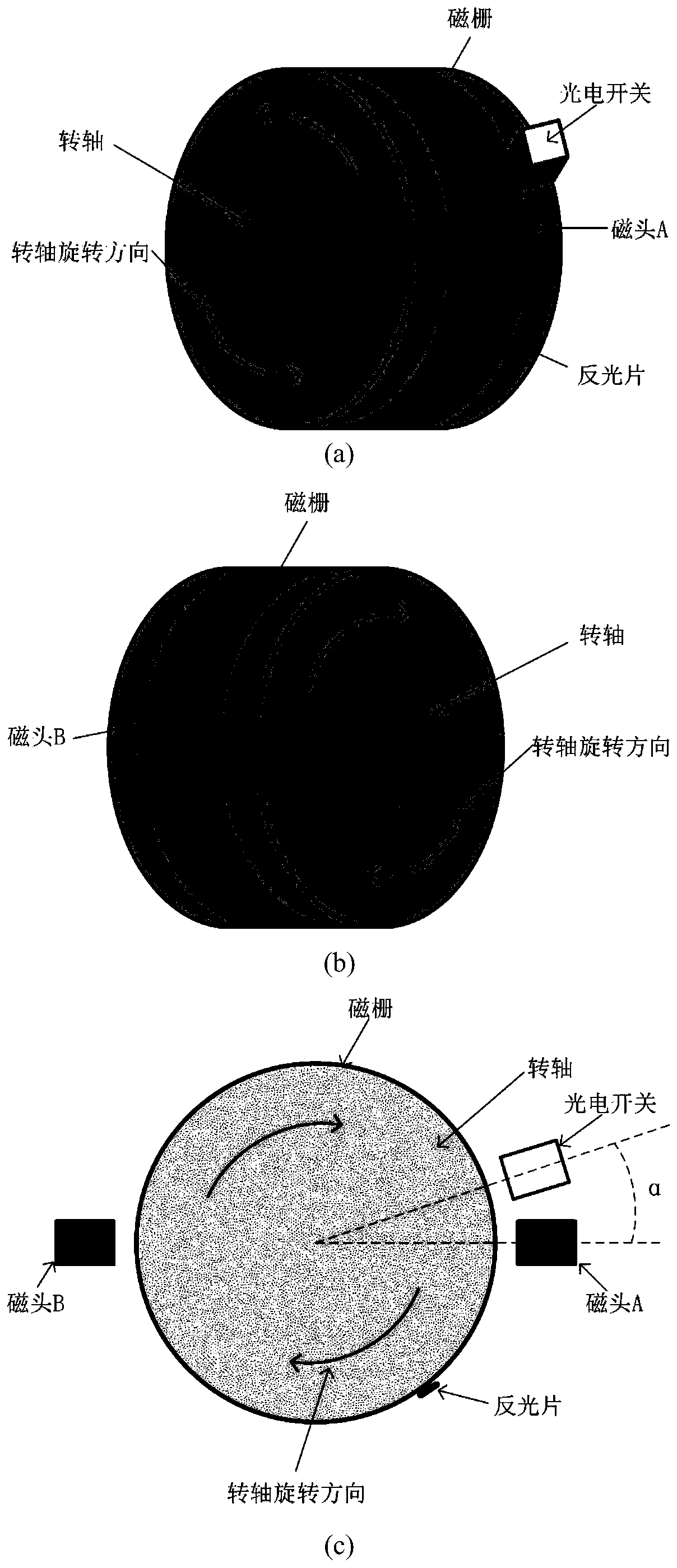

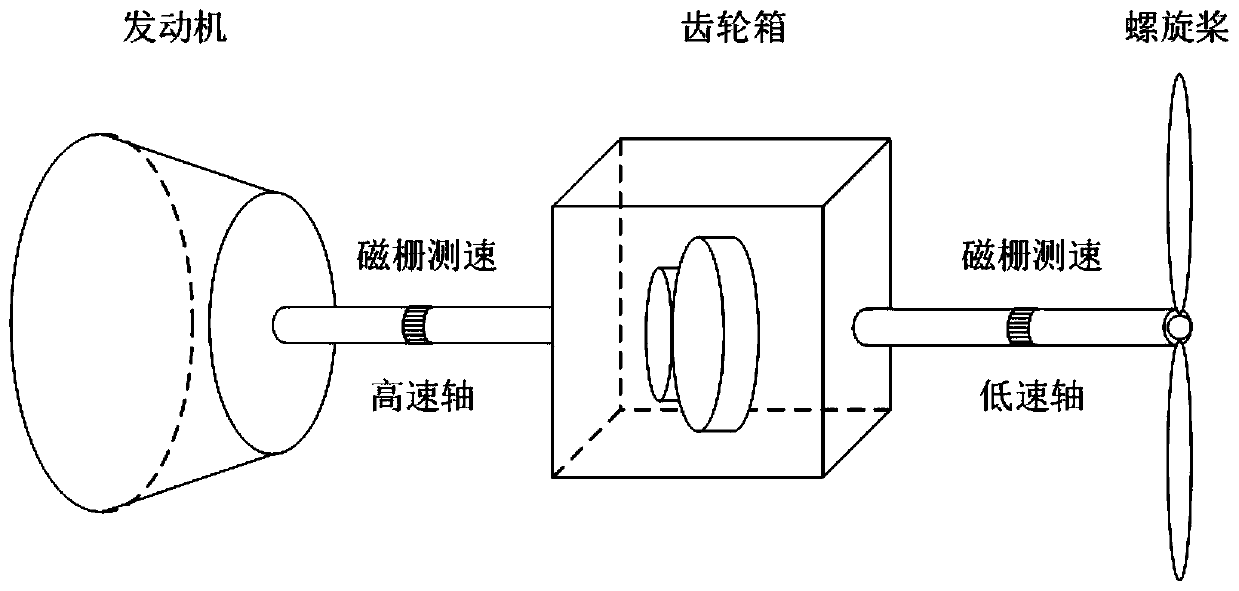

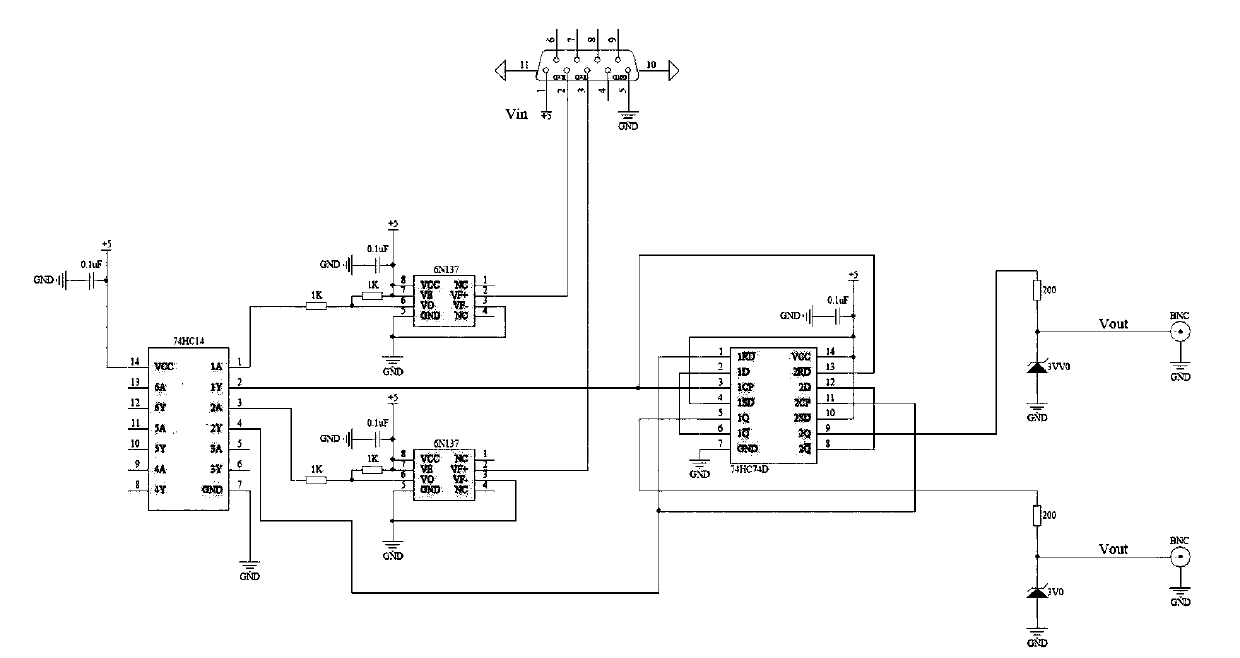

[0027] Such as figure 1 As shown, the ship rotating shafting phase angle measuring device of the present invention includes a magnetic grid strip, a magnetic reading head A, a magnetic reading head B, a photoelectric switch, a reflective sheet, a direction discrimination decoupling circuit, a signal acquisition unit, and a phase angle calculation unit, The magnetic grid strips surround the surface of the ship's rotating shaft to be tested, and the ring formed is coaxial with the rotating shaft to be measured; the magnetic read head A and magnetic read head B are arranged above the magnetic grid bar, symmetrical about the rotating shaft, and the two magnetic read heads The effective sensing surface of the head faces the magnetic grid bar, tangent to the ring of the magnetic grid bar, and the direction of its long side should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com