Device facilitating flanging of bearing ring in tempering furnace

A tempering furnace and inner flanging technology, applied in the field of bearing ring processing, can solve the problems of incapable of bearing ring flanging, affecting the tempering effect, affecting the processing efficiency, etc., so as to remove product stress, improve tempering effect, and improve product qualification. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

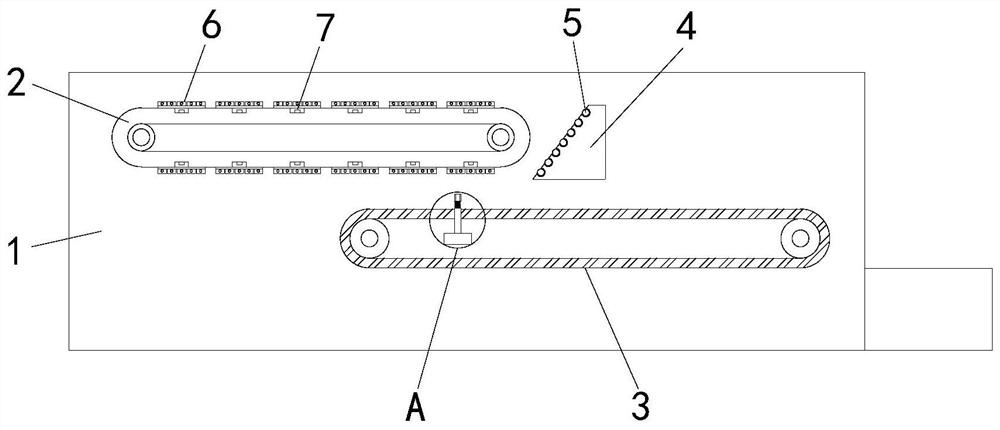

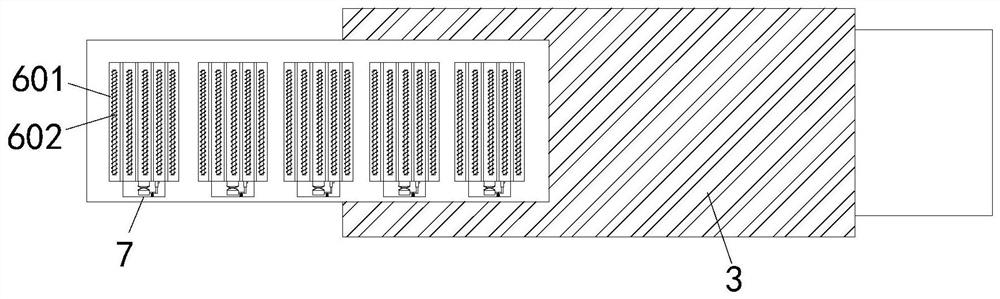

[0029] refer to Figure 1-4 , a device that facilitates the flanging of bearing rings in the tempering furnace, including a tempering furnace 1, a first conveying device 2 and a second conveying device 3, and the first conveying device 2 and the second conveying device 3 are arranged on the side of the tempering furnace 1 At the wall, the first conveying device 2 is located above the second conveying device 3, and one side of the first conveying device 2 is provided with a trapezoidal limiting block 4, and the trapezoidal limiting block 4 is distributed near the outer wall of the first conveying device 2. Group of rigid balls 5;

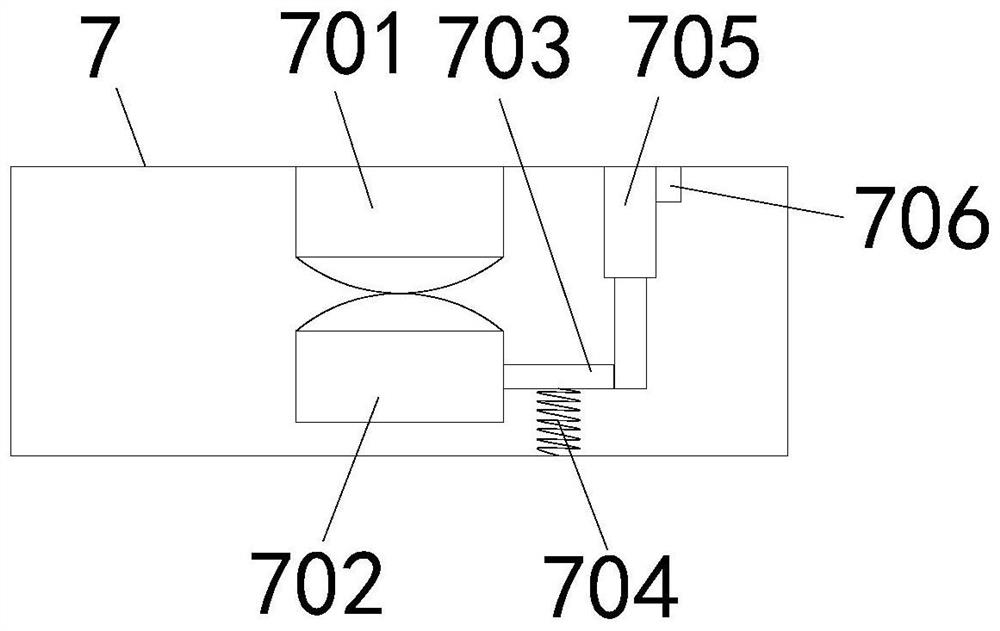

[0030] Several groups of adsorption parts 6 are evenly arranged on the conveyor belt of the first conveying device 2, and one side of the adsorption parts 6 is provided with a control center 7; One side is connected with a connecting rod 703, and one side of the connecting rod 703 is provided with an electric push rod 705, and one side of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com