Preparation method of efficient demulsifier suitable for high-solidification-point crude oil

A technology of demulsifier and crude oil, which is applied in the field of preparation of high-efficiency demulsifier, and can solve problems such as poor separation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0015] The preparation method of the high-efficiency demulsifier suitable for high pour point crude oil comprises the steps of:

[0016] Step S1, use Mannich reaction to react bisphenol A and vinylamine under the condition of feeding N2, heat to 45°C, add formaldehyde solution when the temperature rises to 70°C, react at constant temperature for 1h, and store the reaction product at 120°C-220°C Distill under reduced pressure for 5 hours to obtain the phenolamine resin starter;

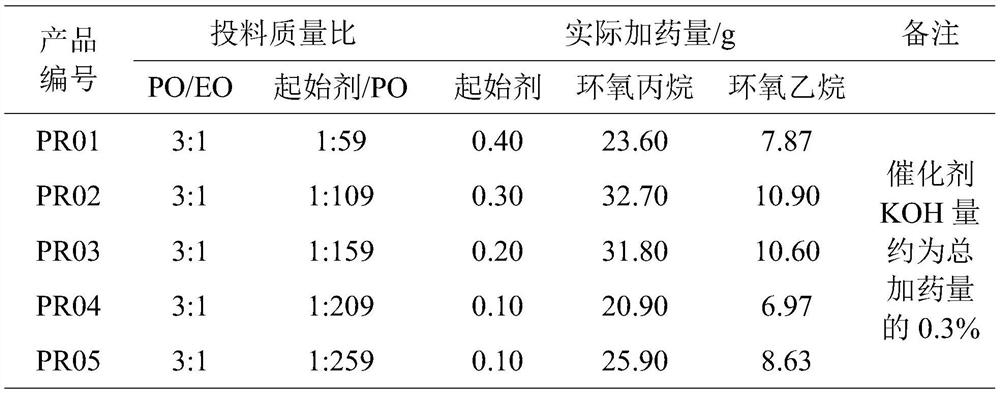

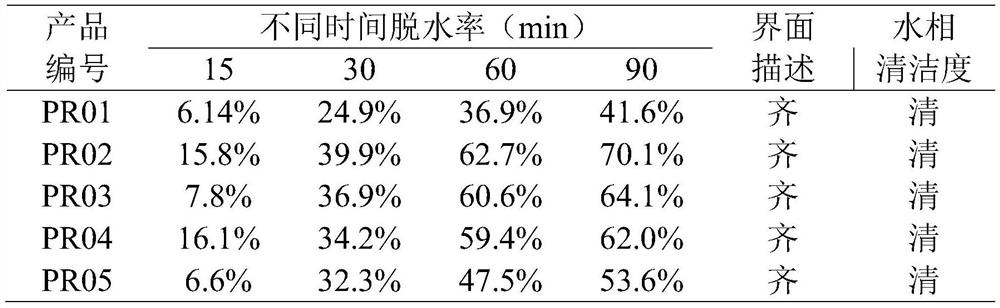

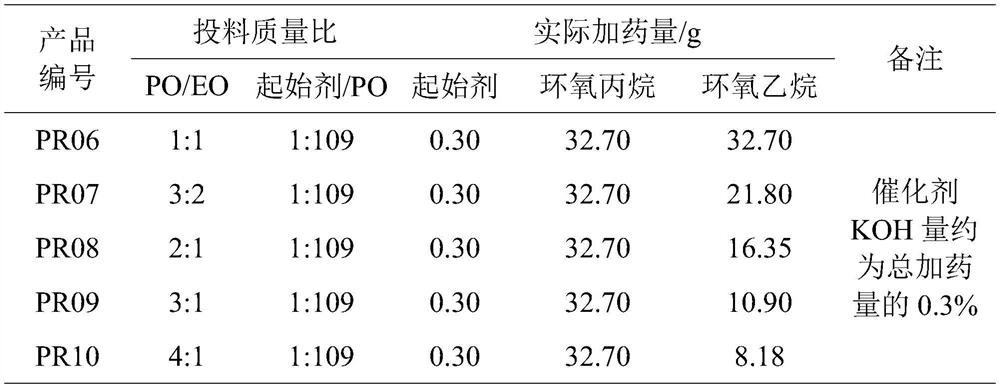

[0017] Step S2, take the phenolamine resin starter and the basic catalyst quantitatively prepared in step S1 and add them to the high-pressure reactor at the same time, seal the reactor system, and when the temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com