Adhesive with energy storage function and application thereof

An adhesive and energy storage technology, applied in the direction of adhesives, non-polymer organic compound adhesives, adhesive types, etc., can solve problems such as non-fluidity, high viscosity and thixotropy of adhesives, and non-curing of adhesive systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] According to a typical embodiment of the present invention, the adhesive matrix includes A component and B component, wherein, A component includes the following components by weight:

[0044] A1. 150-350 parts of vinyl polysiloxane;

[0045] A2. 0.1-5 parts of platinum complex;

[0046] A3. 350-400 copies of energy storage microcapsules;

[0047] A4. 350-400 parts of heat-conducting filler;

[0048] Component B comprises the following components in parts by weight:

[0049] B1. 150-350 parts of vinyl polysiloxane;

[0050] B2. 20-50 parts of hydrogen-containing siloxane;

[0051] B3. Inhibitor 0.05 to 1 part;

[0052] B4. 350-400 copies of energy storage microcapsules;

[0053] B5. 350-400 parts of heat-conducting filler;

[0054] Among them, in the molecular structure of A1 and B1, at least two vinyl groups are connected with silicon atoms, the viscosity at 25°C is 100-10000mpa·s, and the vinyl content is 0.1%-8.0%. The vinyl group can be located at the end of...

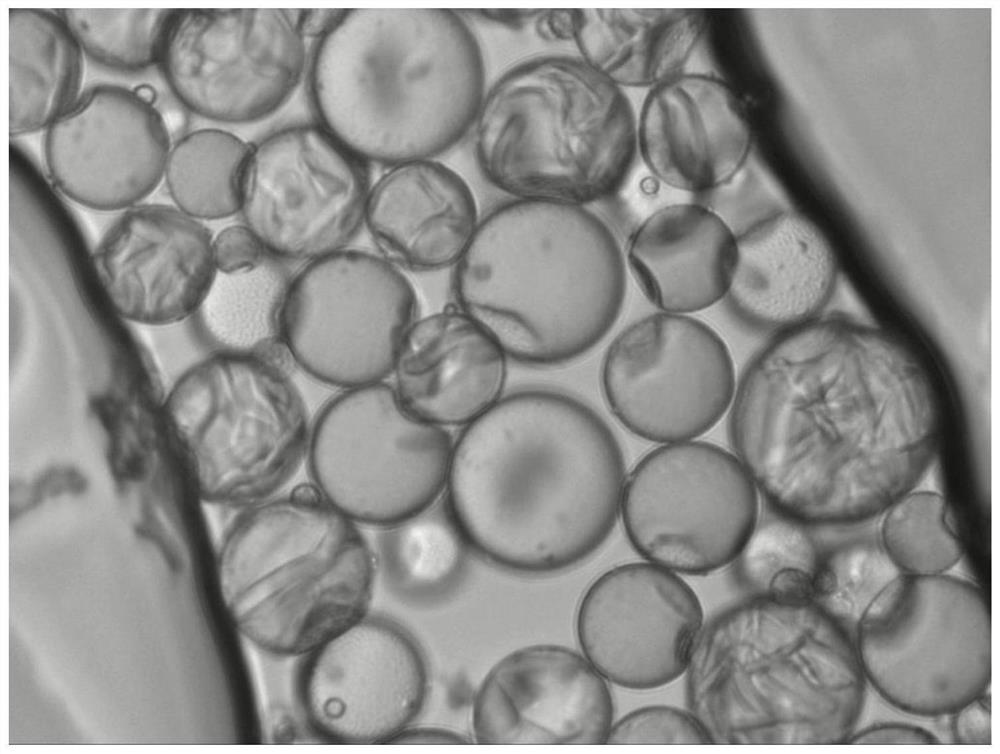

Embodiment 1

[0065] Add 125g deionized water, 1.5g urea, 3g resorcinol, 1.8g gum arabic, 0.3g sodium dodecylbenzenesulfonate, 0.3g ammonium chloride to a 250ml flask, and adjust the pH to 1.2 with 38% hydrochloric acid ~1.3, add 50g 58# paraffin. Raise the temperature to 65°C and emulsify with stirring.

[0066] Keep the temperature at 65°C, add 8.9g of 37% formaldehyde aqueous solution at 0.1ml / min with a constant flow pump, and keep the reaction for 2 hours after the addition is complete.

[0067] Lower the reaction mother liquor to room temperature, let it stand for 2 hours, discard the lower suspension, wash the upper muddy substance twice with deionized water, dry it at 50°C for 2 hours, and pass through an 80-mesh sieve to obtain a powder The product is phase change energy storage microcapsules (energy storage microcapsules).

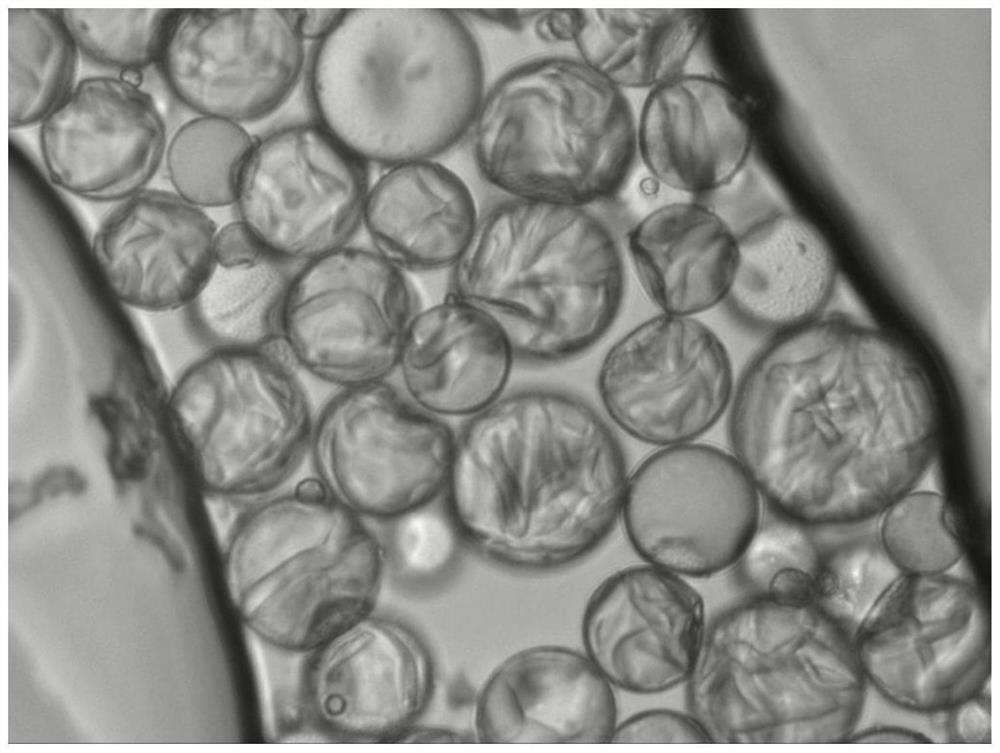

Embodiment 2

[0069] Add 100g of deionized water, 0.5g of urea, 2.5g of phenol, 1.8g of gum arabic, 0.3g of sodium dodecylbenzenesulfonate, 0.3g of ammonium chloride into a 250ml flask, and adjust the pH to 1.2 to 1.3 with 38% hydrochloric acid , add 40g 44# paraffin. Heat up to 55°C and stir to emulsify.

[0070] Keep the temperature at 55°C, add 8.9g of 37% formaldehyde aqueous solution at 0.1ml / min with a constant flow pump, and maintain the reaction for 2 hours after the addition is complete.

[0071] Lower the reaction mother liquor to room temperature, let it stand for 2 hours, discard the lower suspension, wash the upper muddy substance twice with deionized water, dry it at 50°C for 2 hours, and pass through an 80-mesh sieve to obtain a powder The product is a phase change energy storage microcapsule.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com