Inner line demolding structure for plastic product injection mold

A technology for injection molds and products, which is applied in the field of inner texture demoulding structure, can solve the problems of wasting time, weak sealing performance, and increased operation complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

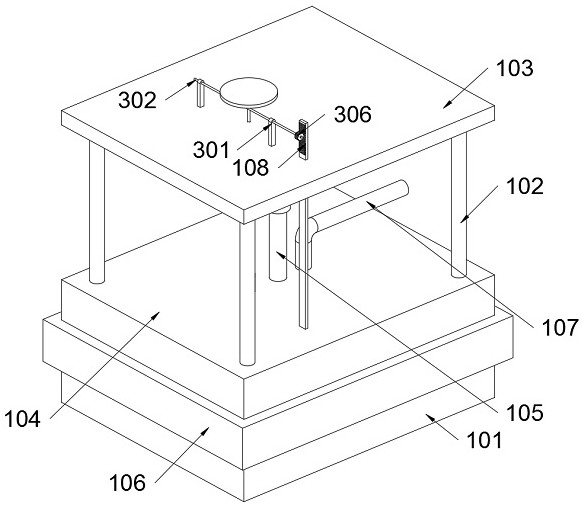

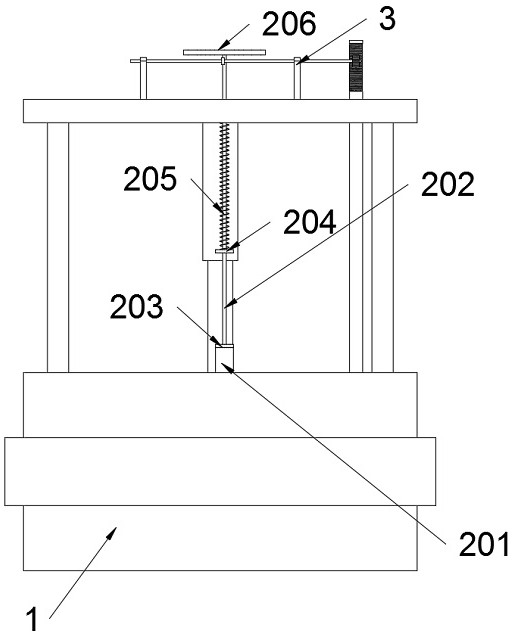

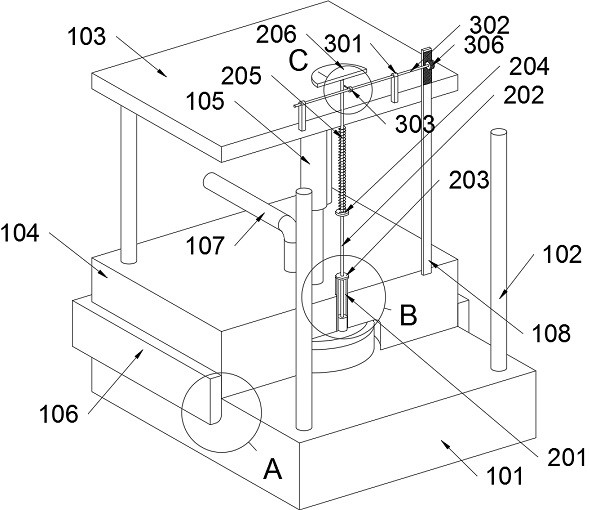

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides a demoulding structure for inner lines of injection molds for plastic products, including a stamping structure 1; the stamping structure 1 consists of a mold seat A101, a sliding rod 102, a top plate 103, a mold seat B104, an electric telescopic rod 105, and an auxiliary seat 106 , the liquid inlet pipe 107 and the tooth row 108, and the stamping structure 1 is equipped with a demoulding part 2, and the stamping structure 1 is also equipped with an auxiliary part 3; the demoulding part 2 includes: a sleeve 201, and the sleeve 201 is welded on On the mold base B104, the piston rod 202 is slidably connected to the casing 201; the piston rod 202 is welded with a baffle A203, and the bottom surface of the baffle A203 is in contact with the top surface of the sleeve 201, and when the bottom surface of the baffle A203 is in contact with the sleeve When the top surface of the tube 201 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com