Integrated high-frequency intelligent leveler and working method thereof

An all-in-one, leveling machine technology, used in forming tools, manufacturing tools, metal processing and other directions, can solve the problems of inability to ensure electromagnetic induction efficiency, easy leakage of power supply, affecting the effect of heating, etc., to improve the effect of heating, The effect of wide application and improved heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

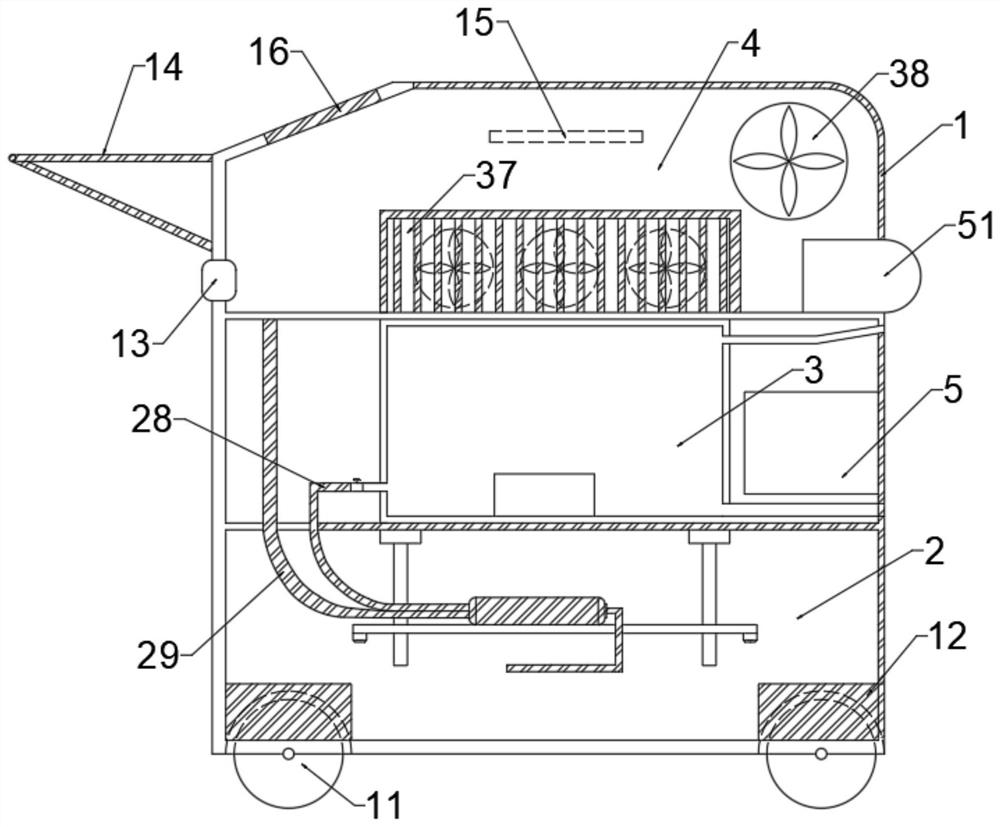

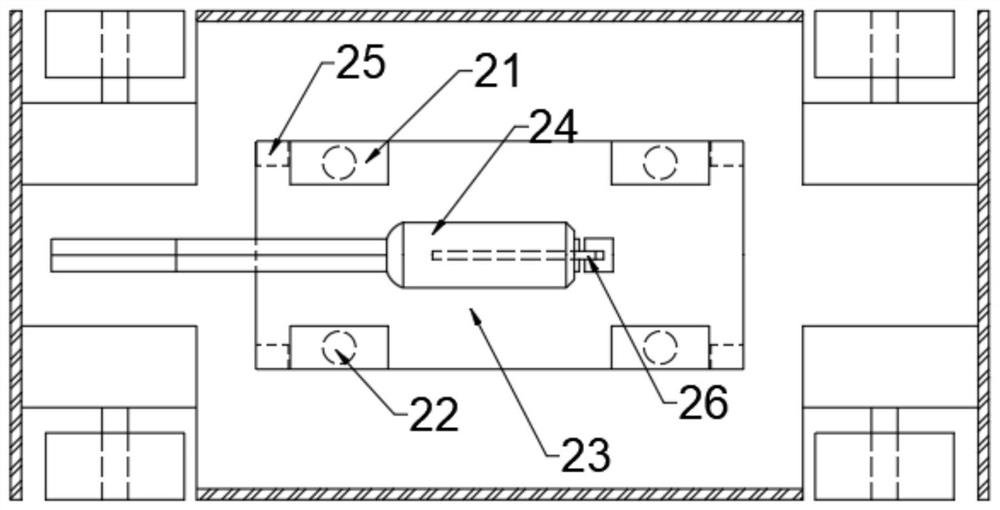

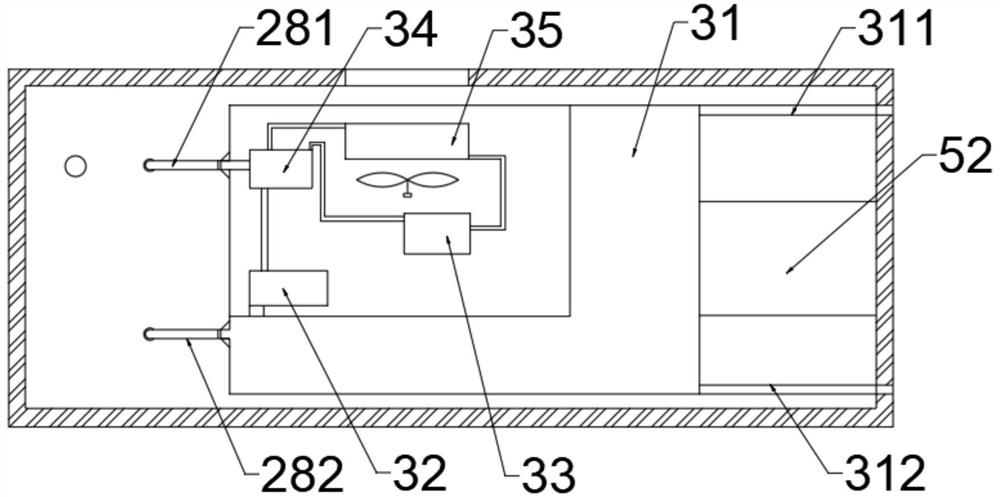

[0040] An integrated high-frequency intelligent leveling machine, such as Figure 1~4 As shown, it includes an integral frame 1 divided into a three-layer structure, and an intelligent heating mechanism 2 arranged on the lower layer of the integral frame 1, a chiller mechanism 3 and a main controller 5 in the middle layer, a high-frequency power supply mechanism 4 in the upper layer, The air-cooling system, the high-definition camera 51, and the layers of the overall frame 1 are separated by steel plates and have via holes on the steel plates to facilitate the layout of signal lines and various pipelines. The overall casing of the leveler is made of plastic material to avoid the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com