Composite reverse osmosis membrane as well as preparation method and application thereof

A technology of reverse osmosis membrane and interfacial polymerization, applied in the field of membrane separation, can solve the problems of few patent reports and complex preparation process of reverse osmosis membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

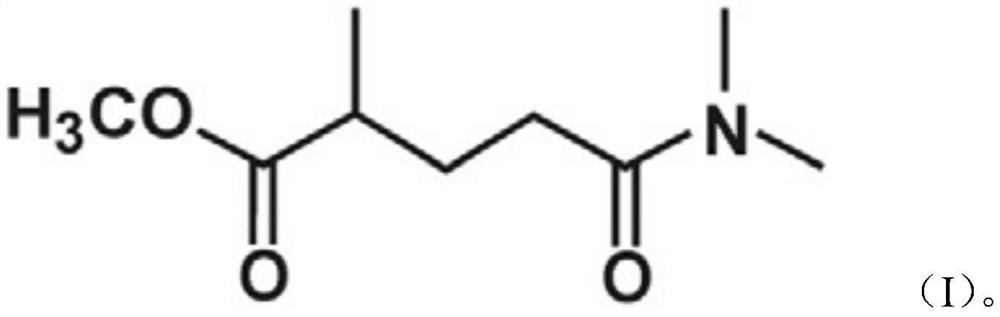

Embodiment 1

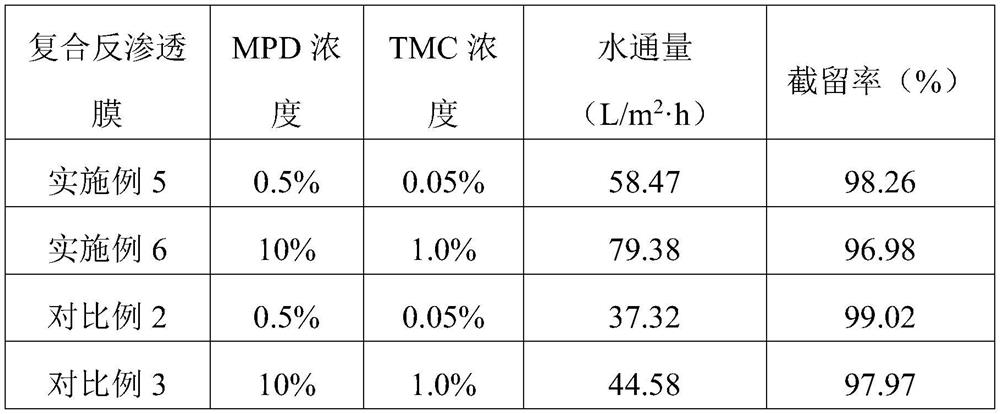

[0054] Weigh a certain amount of water-phase monomer m-phenylenediamine (MPD) in a volumetric flask, adjust the volume to the mark with deionized water, and ultrasonically dissolve to form a homogeneous water-phase solution containing 2.0 wt / v% MPD. Weigh a certain amount of organic phase monomer trimesoyl chloride (TMC) and Polarclean in a volumetric flask, use ISOPAR solvent oil to set the volume to the mark, and ultrasonically dissolve it into a solution containing 0.1wt / v% TMC and 0.01wt / v% Polarclean Homogeneous organic phase solution. Use the above polysulfone porous support base membrane with a molecular weight cut-off of 30,000 to 50,000 to soak and contact the above aqueous phase solution for 60 seconds. Then pour off the excess aqueous phase solution, roll the surface of the membrane dry with a clean rubber roller, and then wet the membrane with the above organic phase solution for 30 seconds. After that, the excess organic phase solution was poured off, and then th...

Embodiment 2

[0057] When preparing the organic phase solution, the mass concentration of the organic phase additive Polarclean added in the homogeneous solution was 0.04%, and the rest of the methods and steps were the same as in Example 1, and the properties of the prepared composite reverse osmosis membrane were listed in Table 1.

Embodiment 3

[0059] When preparing the organic phase solution, the mass concentration of the organic phase additive Polarclean added in the homogeneous solution was 0.1%, and the remaining methods and steps were the same as in Example 1. The properties of the prepared composite reverse osmosis membrane are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com