Polymer ceramic shell and electronic equipment

A technology of ceramic shell and polymer, which is applied in the direction of casing/cabinet/drawer parts, etc., can solve the problems that the preparation method needs to be improved, and achieve the effect of high hardness, excellent wear resistance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

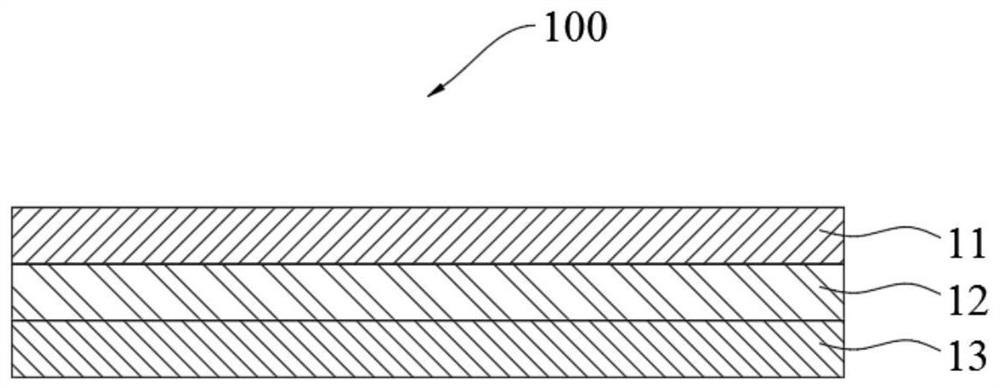

Image

Examples

preparation example Construction

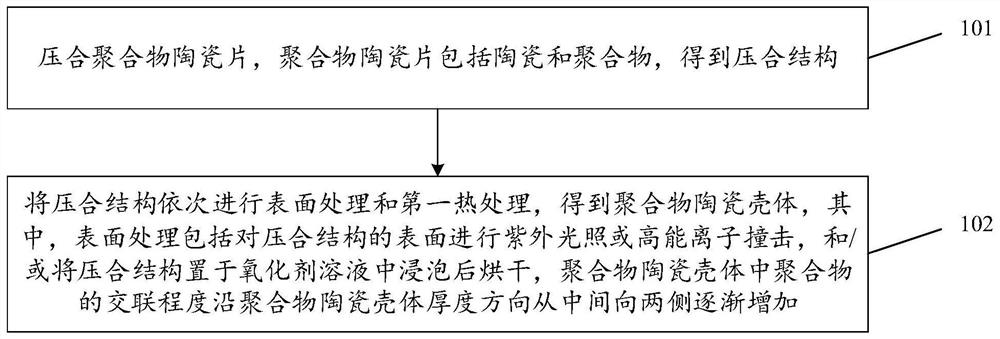

[0036] see image 3 , is a flowchart of a method for preparing a polymer ceramic shell provided in an embodiment of the present application. The preparation method prepares the polymer ceramic shell 100 of any of the above-mentioned embodiments, including:

[0037] Operation 101: Pressing the polymer ceramic sheet, where the polymer ceramic sheet includes ceramic and polymer, to obtain a press bonded structure.

[0038] Operation 102: Perform surface treatment and first heat treatment on the laminated structure in sequence to obtain a polymer ceramic shell, wherein the surface treatment includes performing ultraviolet light or high-energy ion impact on the surface of the laminated structure, and / or placing the laminated structure on After soaking in the oxidant solution and then drying, the degree of cross-linking of the polymer in the polymer ceramic shell gradually increases from the middle to both sides along the thickness direction of the polymer ceramic shell.

[0039] T...

Embodiment 1

[0060] A method for preparing a polymer ceramic shell, comprising:

[0061] The polymer ceramic sheet is subjected to warm isostatic pressing to obtain a pressed structure, wherein the polymer ceramic sheet includes ceramic and polyphenylene sulfide (PPS), and the mass content of the ceramic in the polymer ceramic sheet is 80%.

[0062] The two opposite surfaces (the first surface and the second surface) of the laminated structure are subjected to ultraviolet light, including irradiation at a wavelength of 365nm for 180s; then placed at 310°C for 9 hours to obtain a polymer ceramic shell, a polymer ceramic shell The degree of cross-linking of polyphenylene sulfide gradually increases from the middle to both sides along the thickness direction of the polymer ceramic shell.

Embodiment 2

[0064] A method for preparing a polymer ceramic shell, which is roughly the same as in Example 1, except that ultraviolet light is not used, but high-energy ion impact is performed on the two opposite surfaces of the laminated structure, wherein the incident energy is 300W, The treatment time is 30s, and then placed at 310°C for 9 hours to obtain a polymer ceramic shell. The degree of crosslinking of polyphenylene sulfide in the polymer ceramic shell gradually increases from the middle to both sides along the thickness direction of the polymer ceramic shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com