Construction method of mixing pile based on water-rich organic matter soft soil layer channel

A construction method and organic matter technology, which are applied in basic structural engineering, sheet pile walls, buildings, etc., can solve the problems of low pile strength, and achieve the effects of increasing construction steps, simple construction technology, and ensuring project stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

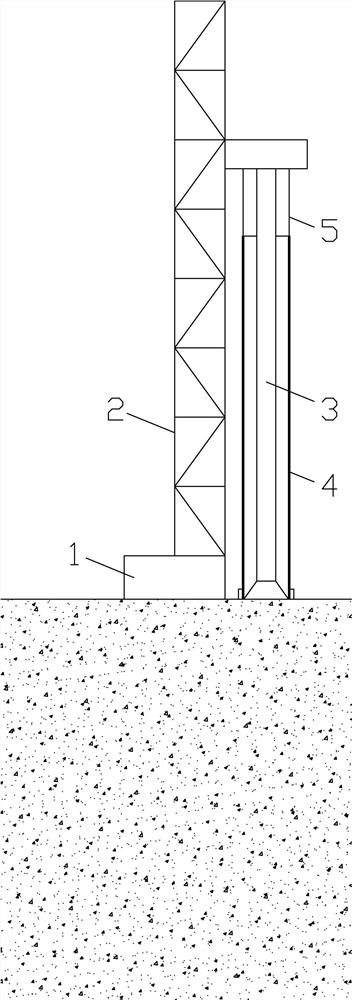

[0040] like Figure 1-5 , a method for constructing a stirring pile based on a water-rich organic matter soft soil layer channel, comprising the following steps:

[0041] 1) Measure the stakeout, mark and determine the position of the pile hole;

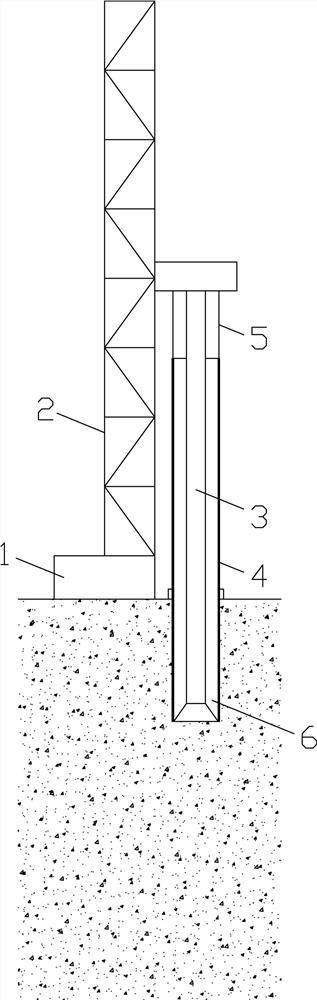

[0042] 2) The pile hole 6 is drilled at the pile position by the drilling rig 1, and the casing 4 is simultaneously lowered during the drilling of the pile hole 6;

[0043] 3) After drilling to the design elevation, stop drilling and pump fine sand;

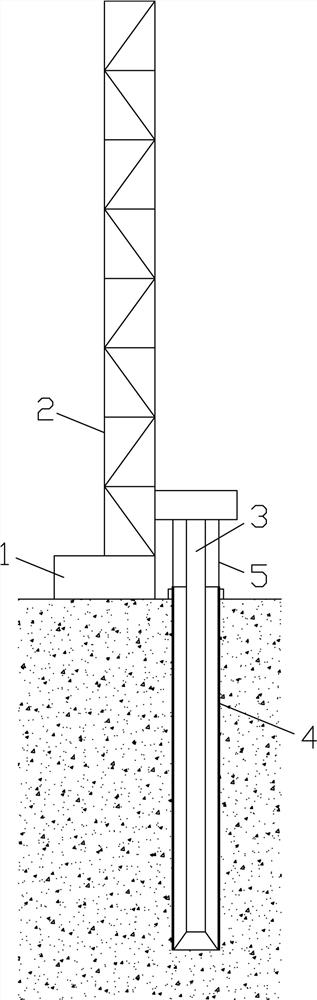

[0044] 4) After the core tube of the drill pipe 3 is filled with fine sand, gradually lift the drill pipe 3 and the second arc plate section 9 of the casing 4;

[0045] 5) After lifting the drill pipe 3 out of the casing 4, stop pumping and form a sand pile 7;

[0046] 6) According to the pile position serial number, use the above method to drill the pile holes 6 in sequence in the subsequent pile positions;

[0047] 7) When the third pile hole 6 is drilled, use the cement pile mixe...

Embodiment 2

[0049] On the basis of Example 1, in the step 4), the lifting speed of the drill pipe 3 and the second arc plate section 9 is controlled at 3.0-4.0m / min, and every 20-30min in the process, the " Pumping-reverse pump-pumping-reverse pump” operation to avoid pipeline blockage;

[0050] Drilling rig 1 in this example uses a CFG long auger;

[0051] In the above construction process, PC220 backhoe was used for removal, and 10t dump truck was used for outbound transportation to avoid the accumulation of dregs in the field.

[0052] In addition, during the construction process, after drilling rig 1 is in place, use the front and rear and left and right vertical benchmarks of drilling rig 1 tower body to check the guide rod of the tower body, correct the position, make the drill rod 3 vertically align with the center of the pile position, and ensure that the CFG long auger is formed into a sand pile The verticality deviation is less than or equal to 1.0%.

Embodiment 3

[0054] On the basis of Example 1, in the step 7), the mixing and spraying operation of the pile hole 6 adopts the method of spraying, rotating and drilling from top to bottom until the designed pile bottom elevation;

[0055] During the lifting process of the cement pile mixer, the method of spraying from bottom to top, rotating while lifting, and lifting the drill is adopted. When the cement pile mixer is lifted to a distance of 0.5m from the ground, the spraying is stopped and the lifting is continued.

[0056] In this example, when the cement pile mixer is drilled to the design elevation of the pile bottom, the in-situ spraying is carried out for 10s to 30s, and then the lifting and spraying mixing operations are carried out.

[0057] The PH-5D cement mixing pile driver is used, and the sinking and lifting speed are controlled at 80cm / min. During the sinking and shotcrete process, the drilling depth, shotcrete elevation and stop surface of the drill should be strictly contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com