Washing liquid prepared from degreased tea seed meal and preparation method of washing liquid

A technology of degreasing tea seeds and washing liquid, which is applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the lack of understanding of the properties of tea saponin, and the lack of full expression of tea saponin and protein in tea seed meal Washing, decontamination and antibacterial ability and other issues, to achieve the effect of reducing the load and difficulty of oxidation decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

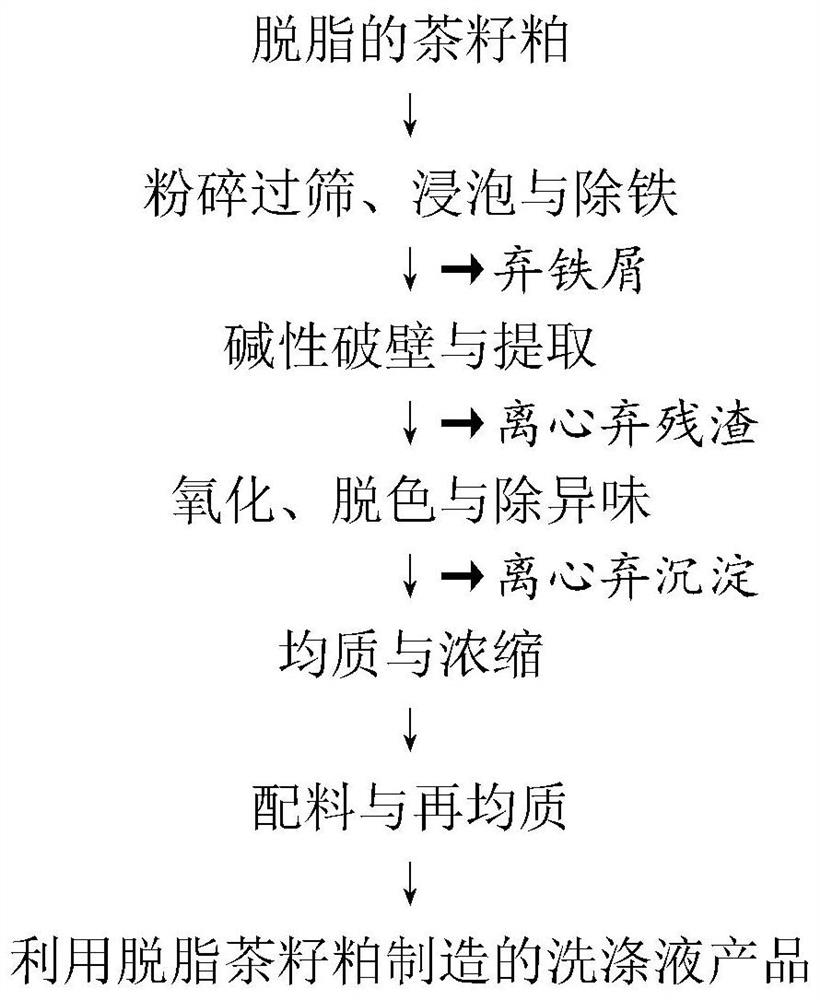

[0042] A kind of method utilizing defatted tea seed dregs to prepare washing liquid, comprises the steps:

[0043] (1) Crushing and sieving, soaking and iron removal: the defatted tea seed meal is pulverized with a stainless steel pulverizer and sieved through a 60-mesh standard sieve to obtain a defatted tea seed meal powder; water, stirred at room temperature for 11 hours, and after the stirring was completed, iron filings in the defatted tea seed meal powder after fully absorbing water and swelling were removed with an iron remover to obtain the soaked mixture of the defatted tea seed meal powder after removing iron filings, and set aside;

[0044] (2) Alkaline wall breaking and extraction

[0045] A. Release tea saponin combined with divalent and polyvalent metal ions: add 0.55% of its mass of sodium carbonate to the soaked mixture of defatted tea seed meal powder obtained in step (1) after removing iron filings, and stir at 60° C. for 1.25 hours , to obtain mixture A aft...

Embodiment 2

[0053] A kind of method utilizing defatted tea seed dregs to prepare washing liquid, comprises the steps:

[0054] (1) Crushing and sieving, soaking and iron removal: the defatted tea seed meal is pulverized with a stainless steel pulverizer and sieved through a 100-mesh standard sieve to obtain the defatted tea seed meal powder; water, stirred at room temperature for 20 hours, and after the stirring was completed, iron filings in the defatted tea seed meal powder after sufficient water absorption and expansion were removed with an iron remover to obtain the soaked mixture of the defatted tea seed meal powder after removing iron filings, and set aside;

[0055] (2) Alkaline wall breaking and extraction

[0056] A. Release the tea saponin combined with divalent and polyvalent metal ions: add 1% of its mass of sodium carbonate to the soaked mixture of defatted tea seed meal powder after iron filings obtained in step (1), and stir for 2 hours at 80° C. , to obtain mixture A afte...

Embodiment 3

[0064] A kind of method utilizing defatted tea seed dregs to prepare washing liquid, comprises the steps:

[0065] (1) Crushing and sieving, soaking and iron removal: the defatted tea seed meal is pulverized with a stainless steel pulverizer and sieved through a 40-mesh standard sieve to obtain a defatted tea seed meal powder; water, stirred at room temperature for 2 hours, and after the stirring was completed, iron filings in the defatted tea seed meal powder after sufficient water absorption and expansion were removed with an iron remover to obtain the soaked mixture of the defatted tea seed meal powder after removing iron filings, and set aside;

[0066] (2) Alkaline wall breaking and extraction

[0067] A. Release tea saponin combined with divalent and polyvalent metal ions: add 0.1% of its mass of sodium carbonate to the soaked mixture of defatted tea seed meal powder obtained in step (1) after removing iron filings, and stir at 40° C. for 0.5 hours , to obtain mixture A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com