Anisotropic thermal conductivity flexible piezoelectric sensor and preparation method thereof

A flexible piezoelectric and anisotropic technology, applied in the direction of using electric/magnetic devices to transfer sensing components, vacuum evaporation plating, coating, etc., can solve the problem of unknown improvement of sensor performance, without considering thermal conductivity and piezoelectricity Capability coupling relationship, few optimization schemes for flexible wearable piezoelectric sensors, etc., to achieve excellent anisotropic thermal conductivity, improved stretchability, and reasonable schemes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

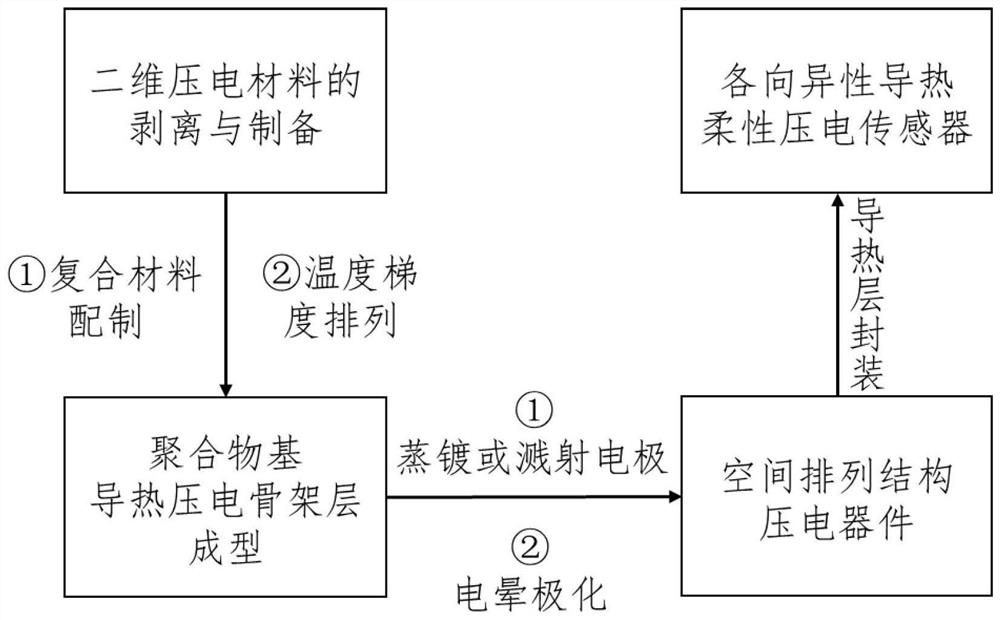

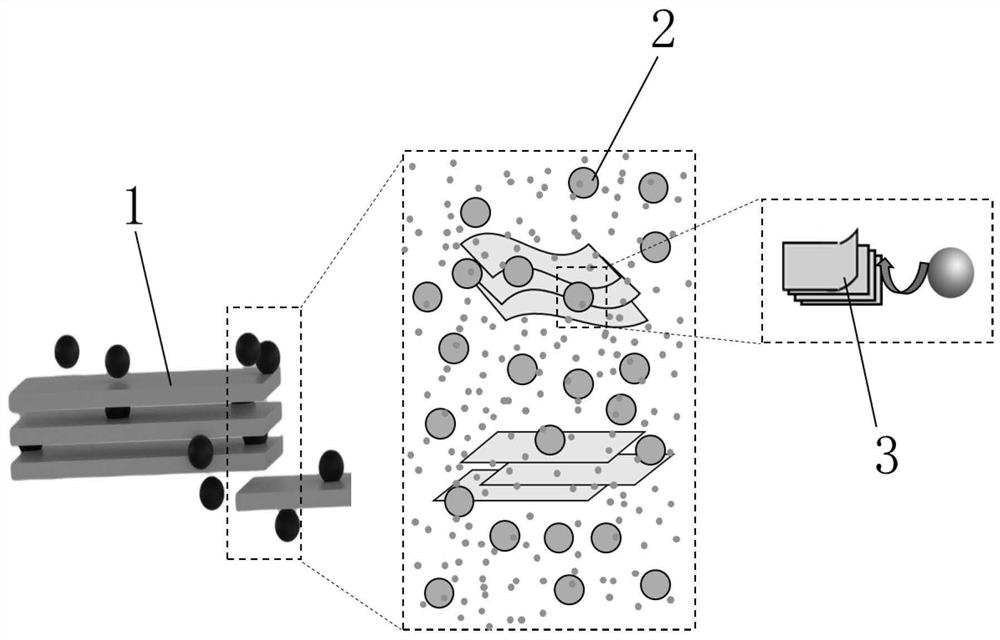

[0044] This example is to realize the molding of an anisotropically thermally conductive flexible piezoelectric sensor encapsulated with epoxy resin, using BNNS as piezoelectric material and PVA as polymer matrix. For the specific preparation process, refer to figure 1 , including the following steps:

[0045] The first step is to exfoliate to prepare 2D BNNS piezoelectric nanosheets

[0046] Principle of peeling method reference figure 2 . Take 4 g of h-BN raw material with a particle size of 13 μm, put it into a 1000 mL beaker, add 800 mL of N,N-dimethylformamide (DMF) to the beaker, and stir well with a glass rod to obtain a mass concentration of 5 mg / mL. dispersion system. It was placed in a cell disruptor, and was ultrasonically disrupted for 4 hours with a horn with a diameter of 20 mm under the parameter of an output power density of 80%. Subsequently, the colloid after ultrasonication was placed in a centrifuge at 2500 rpm for 25 minutes, and the supernatant was t...

Embodiment 2

[0058] This implementation case is to realize molybdenum disulfide (MoS) encapsulation with PDMS 2 ) The forming of the flexible piezoelectric sensor with anisotropic heat conduction in which the nanosheet is a piezoelectric material and TPU is a polymer matrix. For the specific preparation process, refer to figure 1 , including the following steps:

[0059] The first step is to exfoliate to prepare 2D MoS 2 Piezo Nanosheets

[0060] Take MoS with a particle size of 2 μm 2 4 g of raw materials were put into a 1000 mL beaker, 400 mL of deionized water and 400 mL of tert-butanol were added to the beaker, and a dispersion system with a mass concentration of 5 mg / mL was obtained after fully stirring with a glass rod. It was placed in a cell disruptor, and sonicated for 4 hours with a horn with a diameter of 20 mm under the parameter of an output power density of 60%. Subsequently, the colloid after ultrasonication was placed in a centrifuge at 2000 rpm for 25 minutes, and the ...

Embodiment 3

[0070] This example is to realize the molding of anisotropically thermally conductive flexible piezoelectric sensor encapsulated by PDMS, with BNNS as piezoelectric material and TPU-PVA composite material as polymer matrix. For the specific preparation process, refer to figure 1 , including the following steps:

[0071] The first step is to exfoliate to prepare 2D BNNS piezoelectric nanosheets

[0072] Take 4 g of h-BN raw material with a particle size of 13 μm, put it into a 1000 mL beaker, add 800 mL of N,N-dimethylformamide (DMF) to the beaker, and stir well with a glass rod to obtain a mass concentration of 5 mg / mL. dispersion system. It was placed in a cell disruptor, and was ultrasonically disrupted for 4 hours with a horn with a diameter of 20 mm under the parameter of an output power density of 80%. Subsequently, the colloid after ultrasonication was placed in a centrifuge at 2500 rpm for 25 minutes, and the supernatant was taken. The supernatant was poured into a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com