Airflow suspension device and lithium battery production equipment

A suspension device and airflow technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, transportation and packaging, etc., can solve the problems of complex tension control process, low tension control precision, long tension control delay, etc., to shorten the tension control Delay, improve the tension control accuracy, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

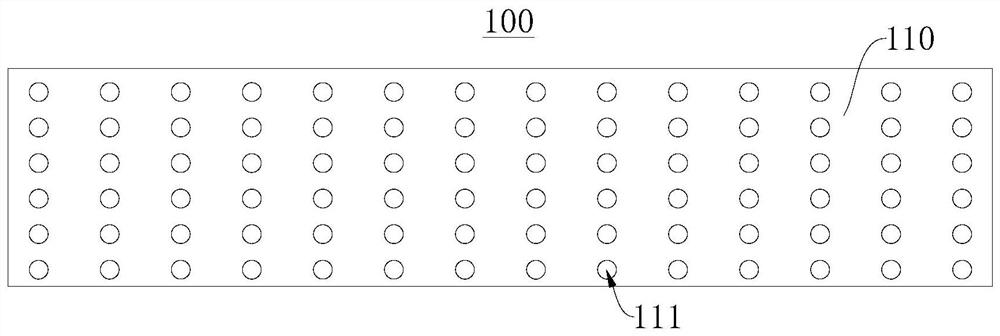

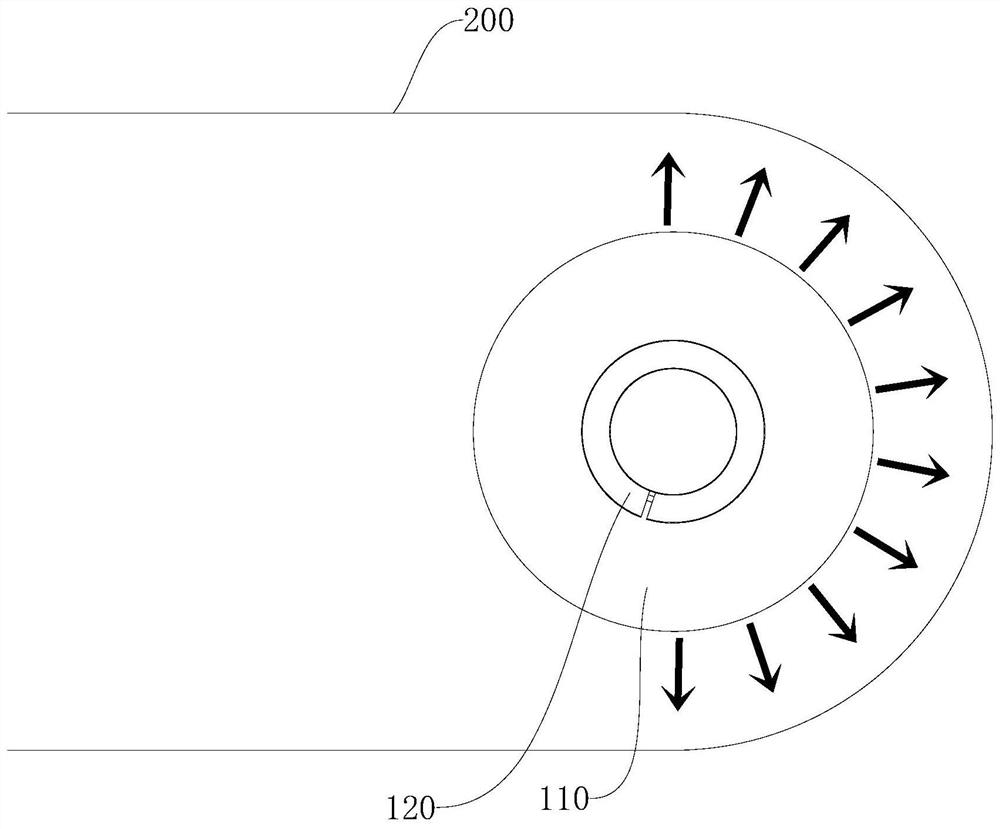

[0043] Please refer to figure 1 , figure 2 and image 3 ( image 3 The arrows in the figure indicate the direction of air flow), the embodiment of the present invention provides a lithium battery production equipment (not shown in the figure), which is used to produce lithium batteries. It can avoid the impact on the tension of the strip 200, simplify the tension control process, improve the tension control precision, shorten the tension control delay, speed up the system response and improve the product quality.

[0044] In this embodiment, the lithium battery production equipment is a winding machine, and the winding machine is used to wind four strips 200 (positive electrode sheet, negative electrode sheet, and two separators) to form a battery cell, and the air suspension device 100 is applied to the winding machine Inside, the air suspension device 100 is used to convey the strip 200, but it is not limited thereto. In other embodiments, the lithium battery production ...

no. 2 example

[0052] Please refer to Figure 4 ( Figure 4 The arrow in the figure indicates the direction of air flow), the embodiment of the present invention provides an air suspension device 100, compared with the first embodiment, the difference of this embodiment is that the area where the shell 110 is provided with the through hole 111 is on the periphery of the shell 110 The upward angles are different.

[0053] In this embodiment, the angle formed by the area of the housing 110 provided with the through hole 111 in the circumferential direction of the housing 110 is 90 degrees, that is, the angle formed by the blowing range of the outlet airflow in the circumferential direction of the housing 110 is 90 degrees. When the wrapping angle of the strip 200 around the shell 110 is 90 degrees, the position where the strip 200 goes around the shell 110 is affected by the wind force of the airflow.

[0054] The beneficial effects of the air suspension device 100 provided by the embodime...

no. 3 example

[0056] Please refer to Figure 5 and Figure 6 ( Figure 6 The arrow in indicates the air flow direction), the embodiment of the present invention provides an air suspension device 100, compared with the first embodiment, the difference of this embodiment is that the air suspension device 100 also includes a first drive motor 130, and the housing The area where the through hole 111 is opened in the housing 110 has different angles in the circumferential direction of the housing 110 .

[0057] In this embodiment, the first driving motor 130 is connected to the casing 110 , and the first driving motor 130 is used to drive the casing 110 to rotate along its axis, and the fan 120 can continuously blow out the airflow during the rotation of the casing 110 . Furthermore, the angle formed by the area of the shell 110 with the through hole 111 in the circumferential direction of the shell 110 is 360 degrees, that is, the angle formed by the blowing range of the outlet airflow in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com