Production device and method of thermoplastic polyimide film

A technology of polyimide film and production equipment, which is applied to other household appliances, flat products, household appliances, etc., can solve problems such as uneven mixing, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

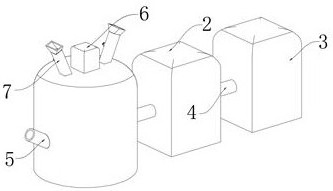

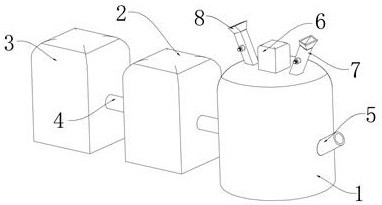

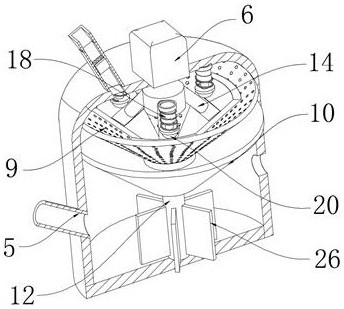

[0032] refer to Figure 1-6 , a thermoplastic polyimide film production device, comprising a reactor 1, a defoaming box 2 and a casting box 3, the reactor 1 and the defoaming box 2, the defoaming box 2 and the casting box 3 are all welded together A connecting pipe 4 is fixed, and the position of the reaction kettle 1 away from the defoaming box 2 is penetrated and fixed with a liquid inlet pipe 5. The top wall of the reactor 1 is symmetrically penetrated and fixed with two feed pipes 7, and the two feed pipes 7 The top wall is welded and fixed with a feed hopper 8, the inner wall of the reactor 1 is welded and fixed with a grinding sleeve 9 and a diversion sleeve 10, a grinding device is installed in the motor sleeve 6, and a vibration device is installed inside the reactor 1. A proportional adjustment device is arranged in the material pipe 7 .

[0033] Grinding device comprises motor 11, and motor 11 is welded and fixed in the inside of motor sleeve 6, and the output shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com