Aquaculture feed feeding device

A technology of aquaculture and feeding device, which is applied in fish farming, application, climate change adaptation, etc., can solve the problem of different particle sizes, and achieve the effect of accurate position, guaranteed precision, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

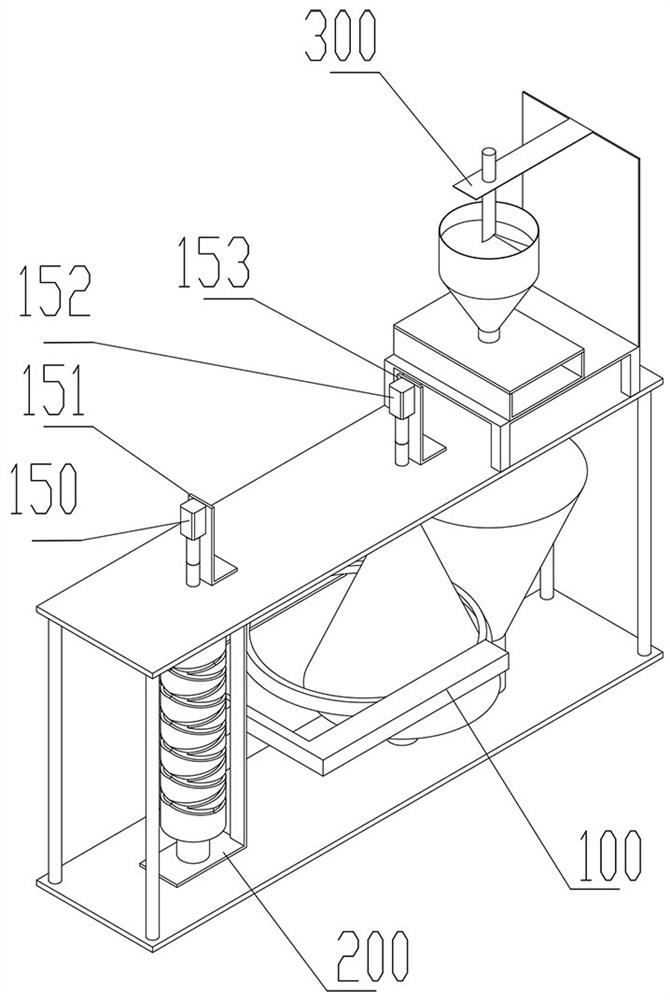

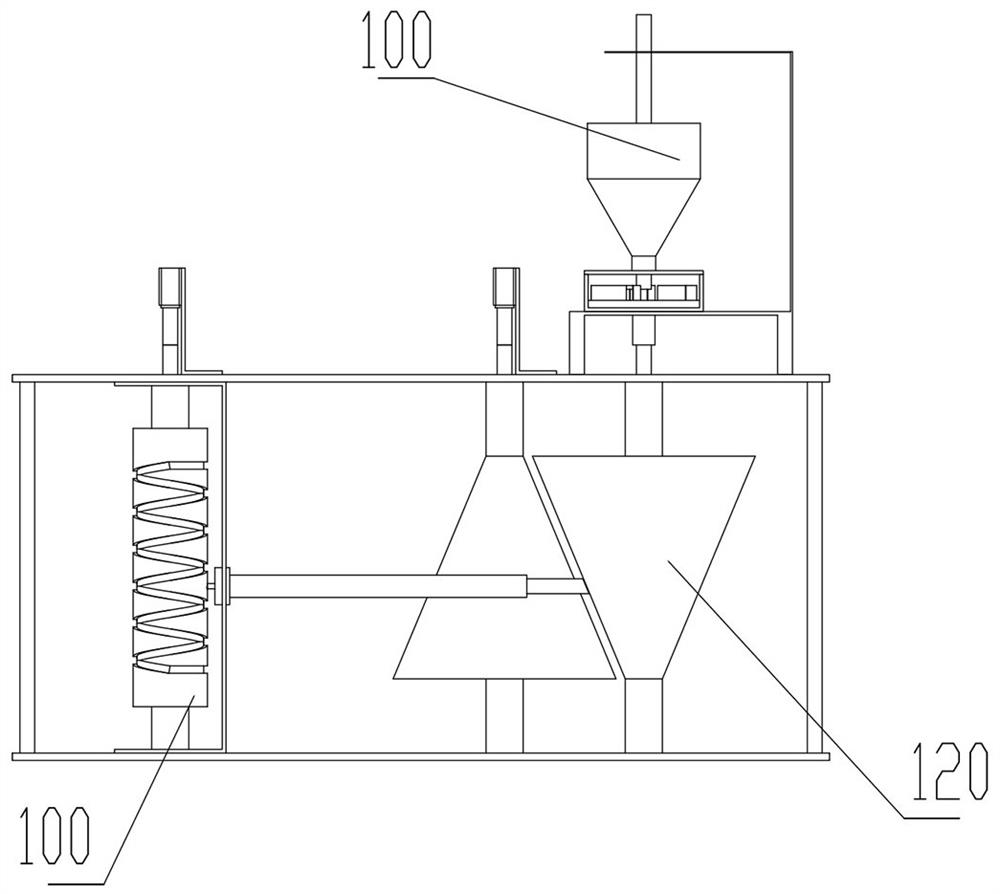

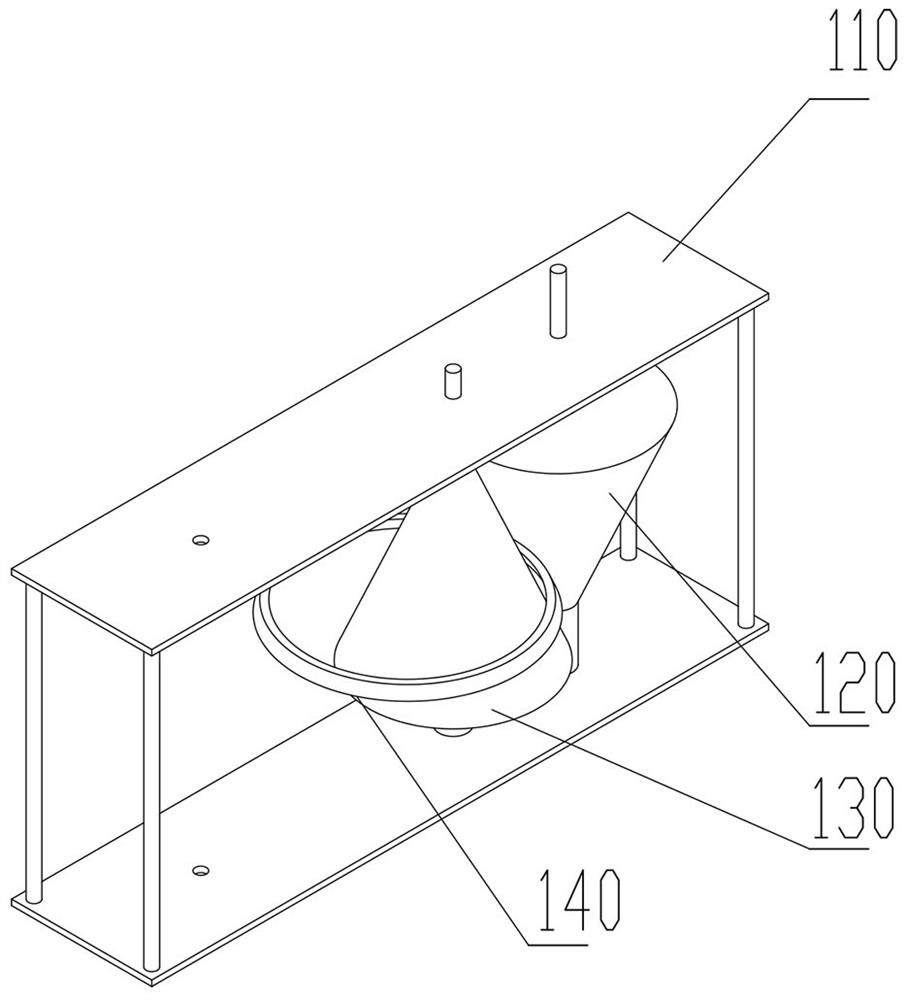

[0026]A feed feeding device for aquaculture, comprising a speed regulating device 100, a reciprocating moving device 200, and a feeding device 300, the speed regulating device 100 comprising a speed regulating frame 110, a main friction wheel 120, a slave friction wheel 130, and a friction ring 140, which reciprocate The device 200 includes a cylindrical cam 210, a cam frame 220, a guide frame 230, and a cam block 240. The feeding device 300 includes a feeding rack 310, a screw shaft 320, a hopper 330, a feeding tray 340, and a discharging tray 350. The speed regulating device 100 is left The inside of the side is connected to the speed regulating device 100 by rotation, and the upper part on the right side of the speed regulating device 100 is fixedly connected to the feeding device 300; The right side has the slave friction wheel hole 111 that runs throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com