Nickel-manganese-cobalt composite hydroxide, production method for nickel-manganese-cobalt composite hydroxide, lithium-nickel-manganese-cobalt composite oxide, and lithium ion secondary battery

A composite hydroxide, composite oxide technology, applied in secondary batteries, nickel compounds, chemical instruments and methods, etc., can solve the problems of output characteristics and battery capacity reduction, deterioration of reactivity of lithium ion secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

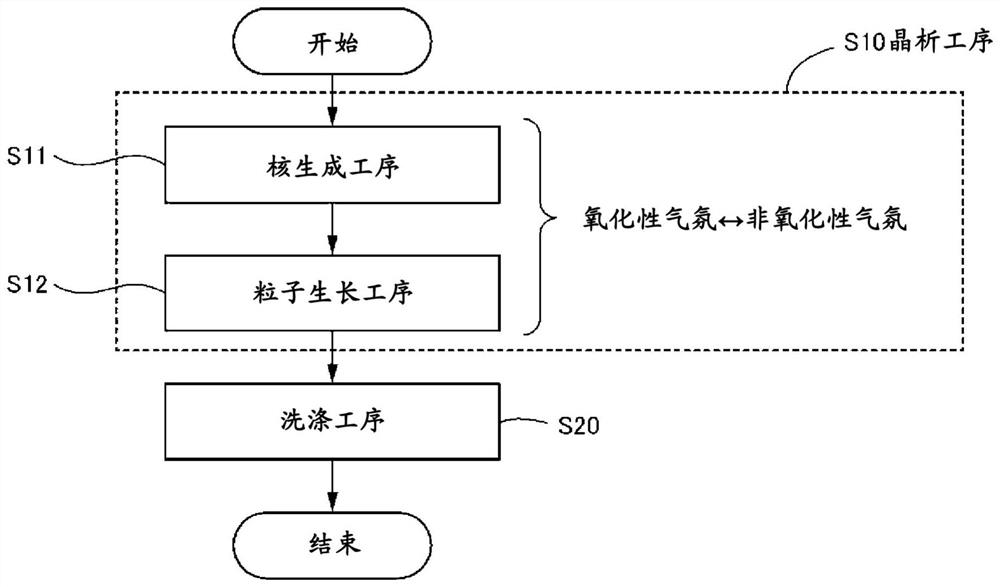

Method used

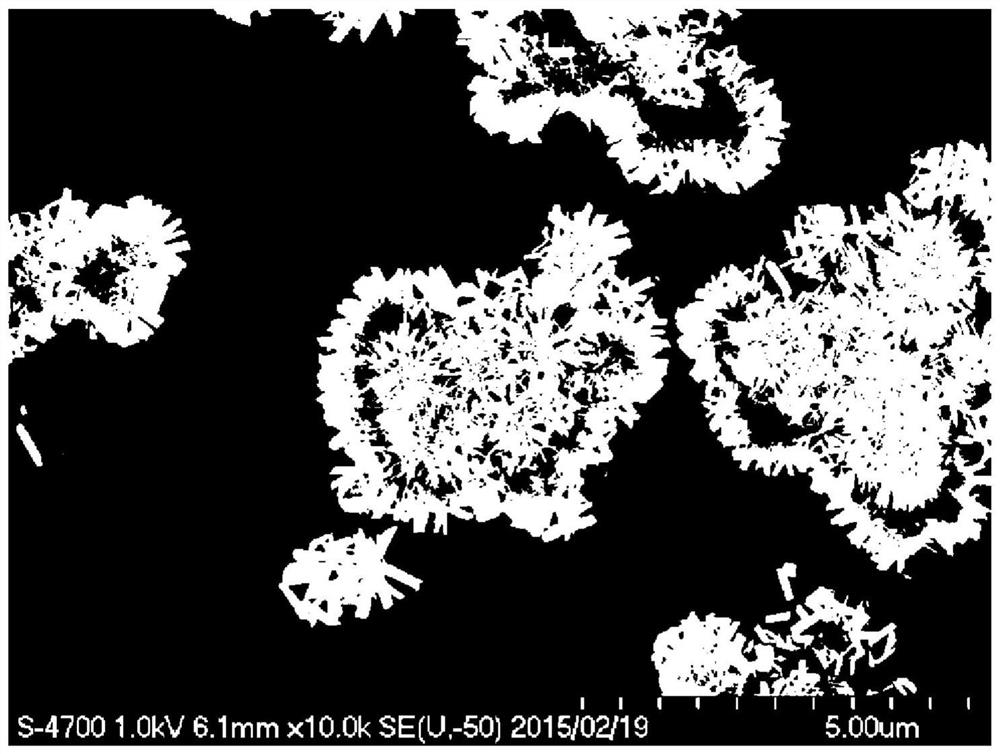

Image

Examples

Embodiment 1

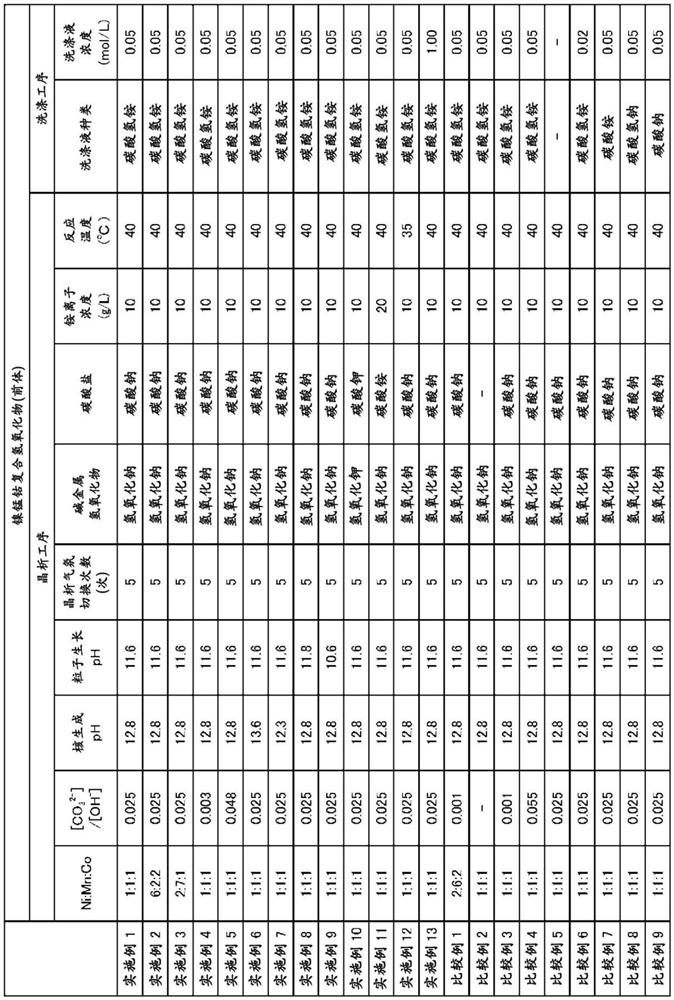

[0253] In Example 1, the temperature in the tank was set to 40° C. while adding 0.9 L of water and stirring in the crystallization reaction tank (5 L) in the crystallization step.

[0254] In the water in the reaction tank, 25% sodium hydroxide aqueous solution and 25% ammonia water as an ammonium ion donor were added in an appropriate amount, and the pH of the reaction solution in the tank was adjusted to 12.8 as the pH measured based on the liquid temperature of 25°C. In addition, the ammonium ion concentration of the reaction solution was adjusted to 10 g / L.

[0255] Next, nickel sulfate, manganese sulfate, and cobalt chloride were dissolved in water to prepare a 2.0 mol / L raw material solution. In this raw material solution, the element molar ratio of each metal was adjusted to Ni:Mn:Co=1:1:1. Further, sodium hydroxide as an alkali metal hydroxide and sodium carbonate as a carbonate were mixed so that [CO 3 2- ] / [OH - ] was dissolved in water so that it became 0.025, a...

Embodiment 2

[0261] In embodiment 2, when nickel sulfate, manganese sulfate, cobalt chloride are dissolved in water to make the raw material solution of 2.0mol / L, the mol ratio of the nickel in the raw material solution, manganese, cobalt is adjusted to Ni:Mn: Except that Co=6:2:2, nickel-manganese-cobalt composite hydroxide was obtained in the same manner as in Example 1.

Embodiment 3

[0263] In embodiment 3, when nickel sulfate, manganese sulfate, cobalt chloride are dissolved in water to make the raw material solution of 2.0mol / L, the mol ratio of the nickel in the raw material solution, manganese, cobalt is adjusted to Ni:Mn: Except that Co=2:7:1, it carried out similarly to Example 1, and obtained the nickel-manganese-cobalt composite hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com