Layer-stranded optical fiber ribbon cable and production process

A technology of optical fiber ribbon and layer stranding, which is applied in the field of layer stranding optical fiber ribbon cable and production technology, and can solve the problems of restricting the mobility of the optical fiber bundle in the optical fiber ribbon, low installation efficiency, and the inability of effective bending and curling of the optical fiber bundle and other issues to achieve the effect of improving physical properties or temperature performance, avoiding damage or destruction, and ensuring peelable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

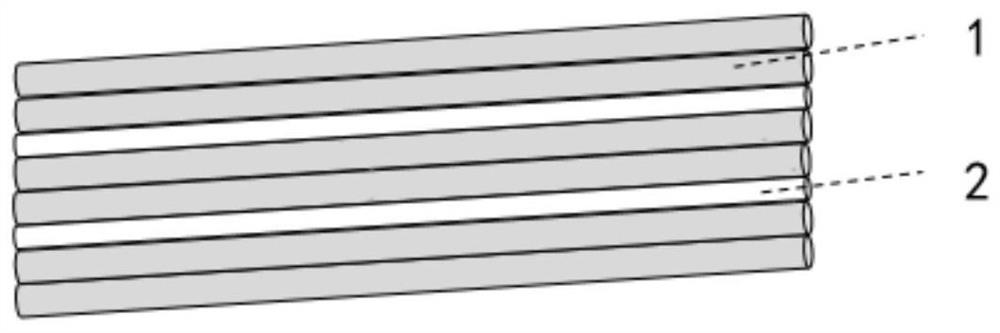

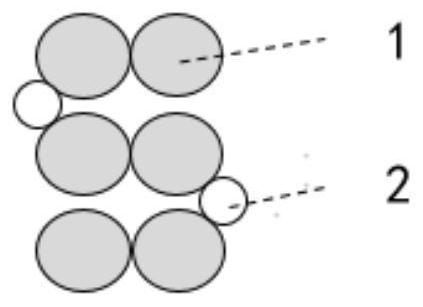

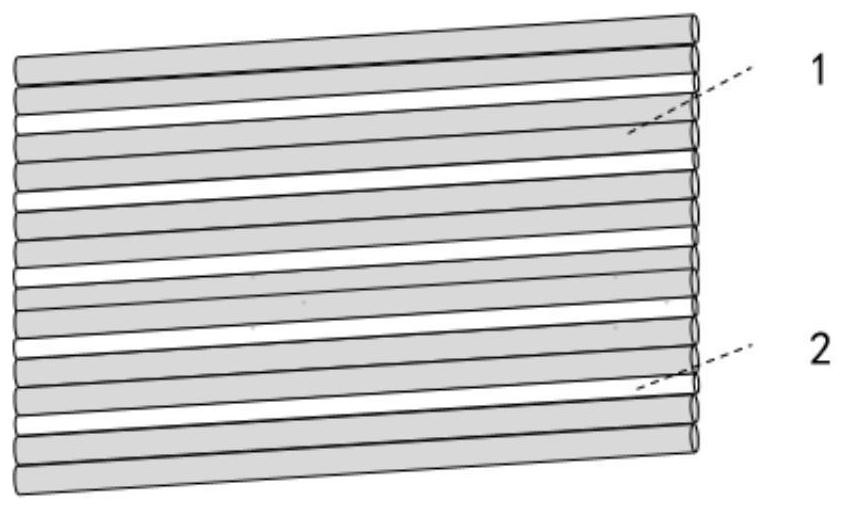

[0033] Such as Image 6 As shown, Embodiment 1 provides a layer-stranded optical fiber ribbon cable, including a plurality of loose tubes 3 in a twisted state and an optical fiber unit installed in the loose tube 3, and the fiber unit and the loose tube A water-blocking filler 4 is filled between them, a central strength member 8 is placed inside a plurality of stranded loose tubes, and a water-blocking tape 7, a metal tape 9 and a sheath layer 6 are placed outside, and the optical fiber unit includes a plurality of bendable The optical fiber ribbon 5, the bendable optical fiber ribbon 5 is a continuous and alternate arrangement of the optical fiber bundle 1 and the bonding layer 2, the optical fiber bundle 1 is formed by combining two optical fibers through UV curing of a photocurable resin, and the bonding layer 2 It is a hot-melt adhesive resin continuously coated between the fiber bundles; the fiber bundle 1 can be bent freely along the axial direction of the adhesive laye...

Embodiment 2

[0052] The structure of embodiment 2 is as Figure 7 As shown, it differs from Embodiment 1 in that: the number of cores of the optical cable is 216 cores, the loose tube 3 is 6 twisted PBT sleeves, and the water blocking filler 4 is Water-blocking powder, the outer diameter of the bonding layer 2 is 120% of the diameter of the optical fiber, the photocurable resin is epoxy resin, the viscosity is 15000cps, the UV curing degree is 70%, and the test condition of MFI (melt index) is: 230 ℃, 2.16kg. The formula used for the bonding layer resin is as follows: 92% polyacrylate, 4% aminosilane, 4% dialkyl peroxide, wherein the melt index of polyacrylate is 40g / 10min, The flexural modulus is 400Mpa; the number of functional groups in the molecular structure of aminosilane is 3. Among them, the peeling force of the bonding layer and the optical fiber bundle is tested on a tensile testing device using a 180° clamp, the tensile rate is 25mm / min, and the peeling force is 1.3N.

Embodiment 3

[0054] The structure of embodiment 3 is as Image 6 As shown, it is different from Embodiment 1 in that: the number of cores of the optical cable is 300 cores, the water blocking filler 4 is water blocking powder, and the central strengthening member 8 is GRP. fiber optic ribbon image 3 , 4 As shown, the optical fiber ribbon in a loose tube has 5 layers, and the optical fiber in the optical fiber ribbon has 12 cores. The outer diameter of the bonding layer 2 is 80% of the diameter of the optical fiber. The optical fiber bundle includes two colored optical fibers and a photocurable resin. The photocurable resin is epoxy resin with a viscosity of 13000cps and a UV curing degree of 63%. The test condition of MFI (melt index) is: 230°C , 2.16kg. The formula used for the bonding layer resin is as follows by weight: 90% polyurethane, 4% aminosilane, 6% peroxycarbonate, the melt index of the polyurethane is 60g / 10min, and the flexural modulus is 400Mpa , In the molecular struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com