Layer-stranded optical fiber ribbon cable and production process thereof

A fiber optic ribbon and layer-stranded technology, which is applied in the field of layer-stranded optical fiber ribbon cable and production technology, can solve the problems of high resin coating modulus, poor flexibility, and small space occupied by optical fibers in loose tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

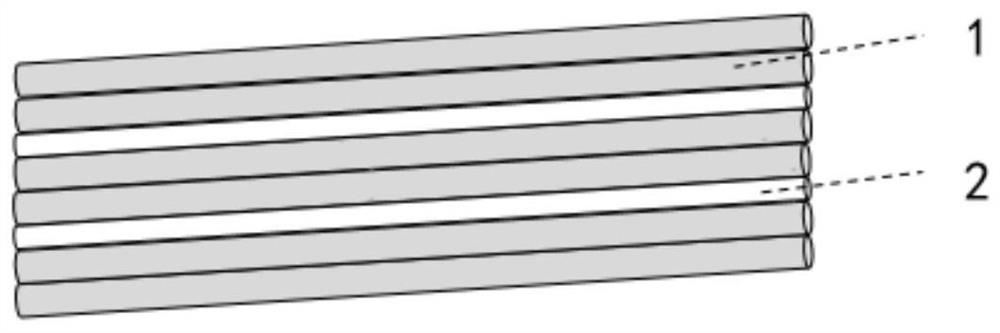

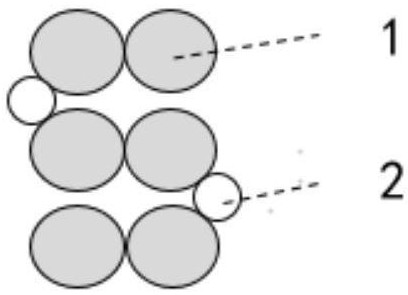

[0033] Such as Figure 6 As shown, Embodiment 1 provides a layer-stranded optical fiber ribbon cable, including a plurality of loose tubes 3 in a twisted state and an optical fiber unit installed in the loose tube 3, and the fiber unit and the loose tube A water-blocking filler 4 is filled between them, a central strength member 8 is placed inside a plurality of stranded loose tubes, and a water-blocking tape 7, a metal tape 9 and a sheath layer 6 are placed outside, and the optical fiber unit includes a plurality of bendable The optical fiber ribbon 5, the bendable optical fiber ribbon 5 is a continuous and alternate arrangement of the optical fiber bundle 1 and the bonding layer 2, the optical fiber bundle 1 is formed by combining two optical fibers through UV curing of a photocurable resin, and the bonding layer 2 It is a hot-melt adhesive resin continuously coated between the fiber bundles; the fiber bundle 1 can be bent freely along the axial direction of the adhesive lay...

Embodiment 2

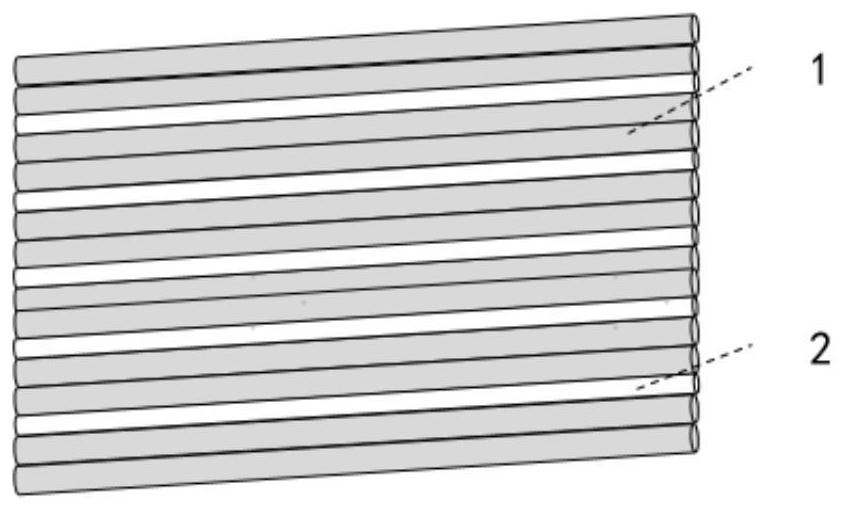

[0052] The structure of embodiment 2 is as Figure 7 As shown, it differs from Embodiment 1 in that: the number of cores of the optical cable is 216 cores, the loose tube 3 is 6 twisted PBT sleeves, and the water blocking filler 4 is Water-blocking powder, the outer diameter of the bonding layer 2 is 120% of the diameter of the optical fiber, the photocurable resin is epoxy resin, the viscosity is 15000cps, the UV curing degree is 70%, and the test condition of MFI (melt index) is: 230 ℃, 2.16kg. The formula used for the bonding layer resin is as follows: 92% polyacrylate, 4% aminosilane, 4% dialkyl peroxide, wherein the melt index of polyacrylate is 40g / 10min, The flexural modulus is 400Mpa; the number of functional groups in the molecular structure of aminosilane is 3. Among them, the peeling force of the bonding layer and the optical fiber bundle is tested on a tensile testing device using a 180° clamp, the tensile rate is 25mm / min, and the peeling force is 1.3N.

Embodiment 3

[0054] The structure of embodiment 3 is as Figure 6 As shown, it is different from Embodiment 1 in that: the number of cores of the optical cable is 300 cores, the water blocking filler 4 is water blocking powder, and the central strengthening member 8 is GRP. fiber optic ribbon image 3 , 4 As shown, the optical fiber ribbon in a loose tube has 5 layers, and the optical fiber in the optical fiber ribbon has 12 cores. The outer diameter of the bonding layer 2 is 80% of the diameter of the optical fiber. The optical fiber bundle includes two colored optical fibers and a photocurable resin. The photocurable resin is epoxy resin with a viscosity of 13000cps and a UV curing degree of 63%. The test condition of MFI (melt index) is: 230°C , 2.16kg. The formula used for the bonding layer resin is as follows by weight: 90% polyurethane, 4% aminosilane, 6% peroxycarbonate, the melt index of the polyurethane is 60g / 10min, and the flexural modulus is 400Mpa , In the molecular struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com