Deep groove excavation construction technology

A construction technology and deep trench technology, applied in excavation, infrastructure engineering, pipeline laying and maintenance, etc., can solve the problem of increasing the auxiliary process time of trench excavation construction, affecting the efficiency of trench excavation construction, and the installation of supporting devices is time-consuming and laborious To achieve the effect of shortening the auxiliary process time, shortening the construction period and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

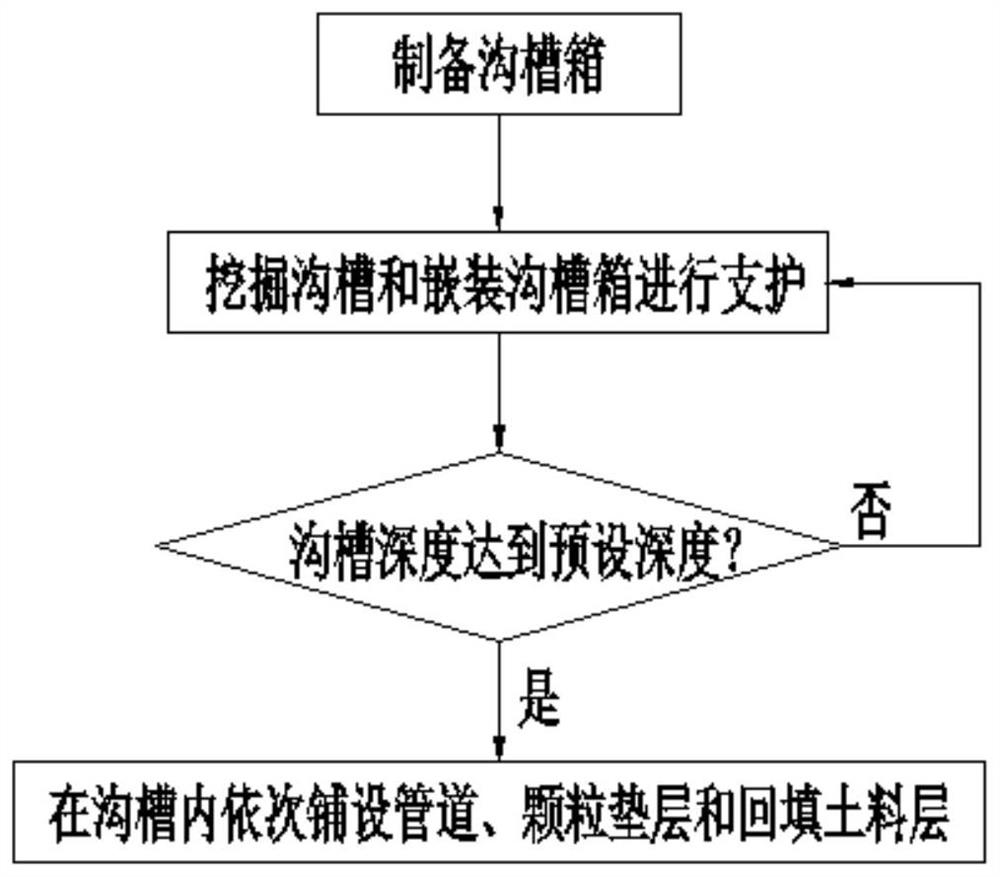

[0021] Such as figure 1 As shown, the present invention provides a kind of deep trench excavation construction technique, comprises the following steps:

[0022] Step 1: prepare a plurality of grooved boxes, the grooved boxes are hollow up and down and include a pair of support plates parallel to each other, a plurality of support bars are fixedly connected between the pair of support plates, and the plurality of support bars are along the The support plates are arranged in a linear array at equal intervals in the length direction; further, preferably, the material of the support plates is wood. The material of the struts is wood. The strut is in the shape of a cylinder with an outer diameter not less than 100mm. The length of the support plate is 4m, and its thickness is not less than 50mm,

[0023] Step 2: When the user needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com