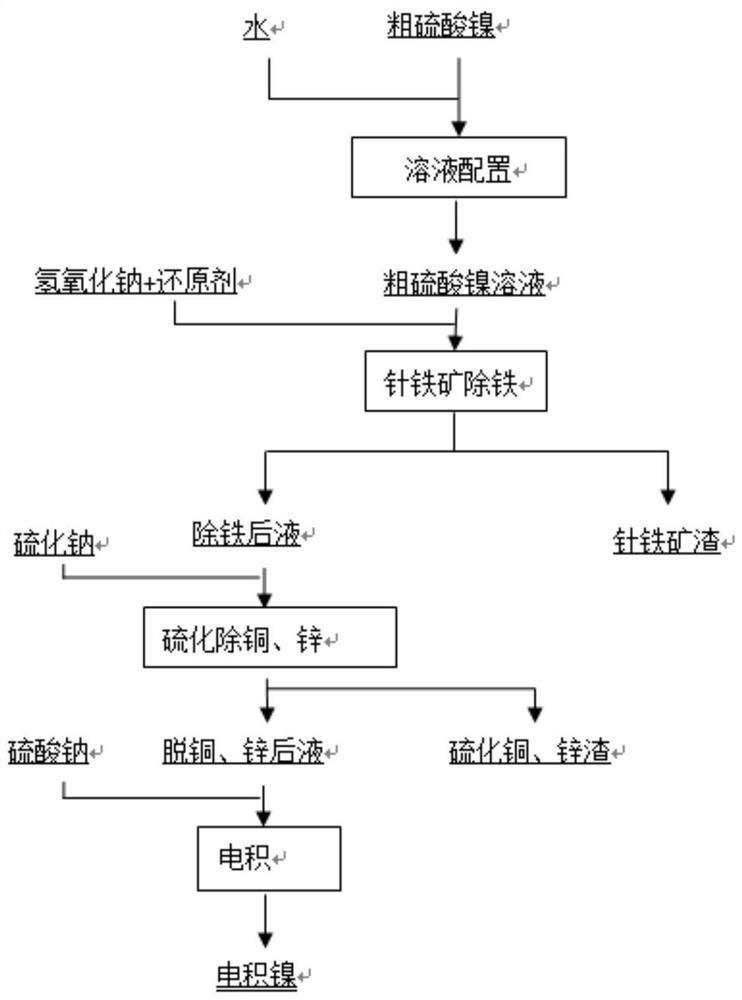

Method for preparing electrodeposited nickel by using crude nickel sulfate

A technology of nickel sulfate and electrowinning, applied in electrolytic process, electrolytic components, photographic technology, etc., can solve problems such as low production efficiency, high requirements for raw material composition, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Configuration of crude nickel sulfate solution. Dissolve 1t of crude nickel sulfate with water, turn on stirring and pass steam, control the dissolving temperature at 70°C, and dissolve the time in 30 minutes; 2m after dissolving 3 Composition of crude nickel sulfate solution in solution: Ni88.4g / L, Cu 4.08g / L, Fe 10.5g / L, As 0.56g / L, Pb0.034g / L, Zn 23.75g / L, H 2 SO 4 50g / L.

[0032] (2) Goethite iron removal. The temperature of the crude nickel sulfate solution was heated to 93 ° C, and 24 kg of goethite crystal seeds were added to the dissolved nickel sulfate solution; 2 gas, and control the concentration of ferric iron not to exceed 2g / L; then adjust the pH of the solution to 3.0 with sodium hydroxide, and react until the precipitate in the solution is no longer produced. Filter, the filter residue is goethite slag. 2.2m 3 Components in the liquid after filtration: Ni 78.6g / L, Cu 3.6g / L, Fe 0.004g / L, As 0.35g / L, Pb 0.015g / L, Zn 21.4g / L.

[0033] (3) Sulfu...

Embodiment 2

[0037] (1) Configuration of crude nickel sulfate solution. Dissolve 1t of crude nickel sulfate with water, turn on stirring and pass steam, control the dissolving temperature at 70°C, and dissolve the time in 30 minutes; 2.1m after dissolving 3 Composition of crude nickel sulfate solution in solution: Ni100g / L, Cu 6.2g / L, Fe 11.4g / L, As 2.2g / L, Pb 0.056g / L, Zn 27.8g / L, H 2 SO 4 65g / L.

[0038] (2) Goethite iron removal. The temperature of the crude nickel sulfate solution was heated to 90°C, and 25.2 kg of goethite crystal seeds were added to the dissolved nickel sulfate solution; 2 gas, and control the concentration of ferric iron not to exceed 2g / L; then adjust the pH of the solution to 3.5 with sodium hydroxide, and react until the precipitate in the solution is no longer produced. Filter, the filter residue is goethite slag. 2.3m 3 Components in the liquid after filtration: Ni 91g / L, Cu 5.4g / L, Fe 0.004g / L, As 0.055g / L, Pb 0.03g / L, Zn 25.2g / L.

[0039] (3) Sulfuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com