Magnesium phosphate cement-based sulfate-resistant maritime work repairing and reinforcing material and preparation method thereof

A magnesium phosphate cement and sulfate-resistant technology, which is applied in the field of building materials, can solve the problems of low alkalinity, poor concrete cohesion, and poor wear resistance, and achieve the effects of high early strength, fast setting and hardening, and strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

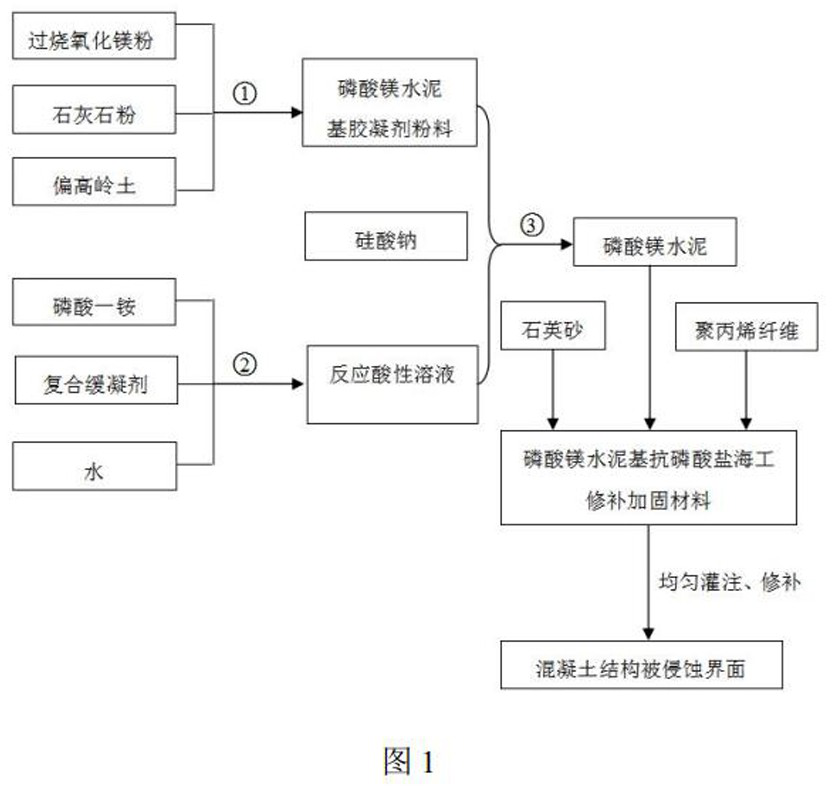

[0028] A magnesium phosphate cement-based anti-sulfuric acid marine repair and reinforcement material, which is made of magnesium phosphate cement, quartz sand, polypropylene fiber and water:

[0029] Magnesium phosphate cement-based gelling agent powder is calculated by mass percentage: 80.0% overburned magnesium oxide, 6.0% limestone powder, and 14.0% metakaolin.

[0030] The massfraction of described overburned magnesium oxide powder is 92%, and the specific surface area of overburned magnesium oxide powder ; The limestone powder, 0.063mm square hole sieve remaining 3%; The average particle size of the metakaolin is 1.5~2.5µm, the specific surface area .

[0031] Magnesium phosphate cement is calculated by mass percentage: magnesium phosphate cement-based gelling powder 63.0%, monoammonium phosphate 22%, composite retarder 11%, and sodium silicate 4%.

[0032] The main particle size of the monoammonium phosphate is 40 / 350~60 / 245 mesh / μm, and the composite retarder is ...

Embodiment 2

[0046] A magnesium phosphate cement-based anti-sulfuric acid marine repair and reinforcement material, which is made of magnesium phosphate cement, quartz sand, polypropylene fiber and water:

[0047] Among them, the magnesium phosphate cement-based gelling agent powder is calculated by mass percentage: 82.0% of overburned magnesium oxide, 5.0% of limestone powder, and 13.0% of metakaolin;

[0048] Magnesium phosphate cement is calculated by mass percentage: magnesium phosphate cement-based gelling powder 64.0%, monoammonium phosphate 21%, composite retarder 11%, sodium silicate 4%;

[0049] Magnesium phosphate cement-based sulfate-resistant repair and reinforcement materials are calculated by mass fraction: magnesium phosphate cement 55.0%, quartz sand 44.0%, polypropylene fiber 1.0%.

[0050] The preparation method and use method of the magnesium phosphate cement-based sulfate-resistant offshore repair reinforcement material in Example 2 are the same as those in Example 1. ...

Embodiment 3

[0055] A magnesium phosphate cement-based anti-sulfuric acid marine repair and reinforcement material, which is made of magnesium phosphate cement, quartz sand, polypropylene fiber and water:

[0056] Among them, the magnesium phosphate cement-based gelling agent powder is calculated by mass percentage: 80.0% of overburned magnesium oxide, 5.0% of limestone powder, and 15.0% of metakaolin;

[0057] Magnesium phosphate cement is calculated by mass percentage: magnesium phosphate cement-based gelling powder 65.0%, monoammonium phosphate 22%, composite retarder 10%, sodium silicate 3%;

[0058] Magnesium phosphate cement-based sulfate-resistant repair and reinforcement materials are calculated by mass fraction: magnesium phosphate cement 56.0%, quartz sand 43.2%, polypropylene fiber 0.8%.

[0059] The preparation method and use method of the magnesium phosphate cement-based sulfate-resistant marine repair reinforcement material in Example 3 are the same as in Example 1.

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com