A kind of semi-permeable travertine dry granule and preparation method thereof

A technology of dry granules and travertine, applied in the field of new dry granules and their preparation, semi-permeable travertine dry granules and their preparation fields, can solve the problems of difficult product quality control, low density of dry granule products, unfavorable use, etc. Realistic, Inexpensive, Clearly Textured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

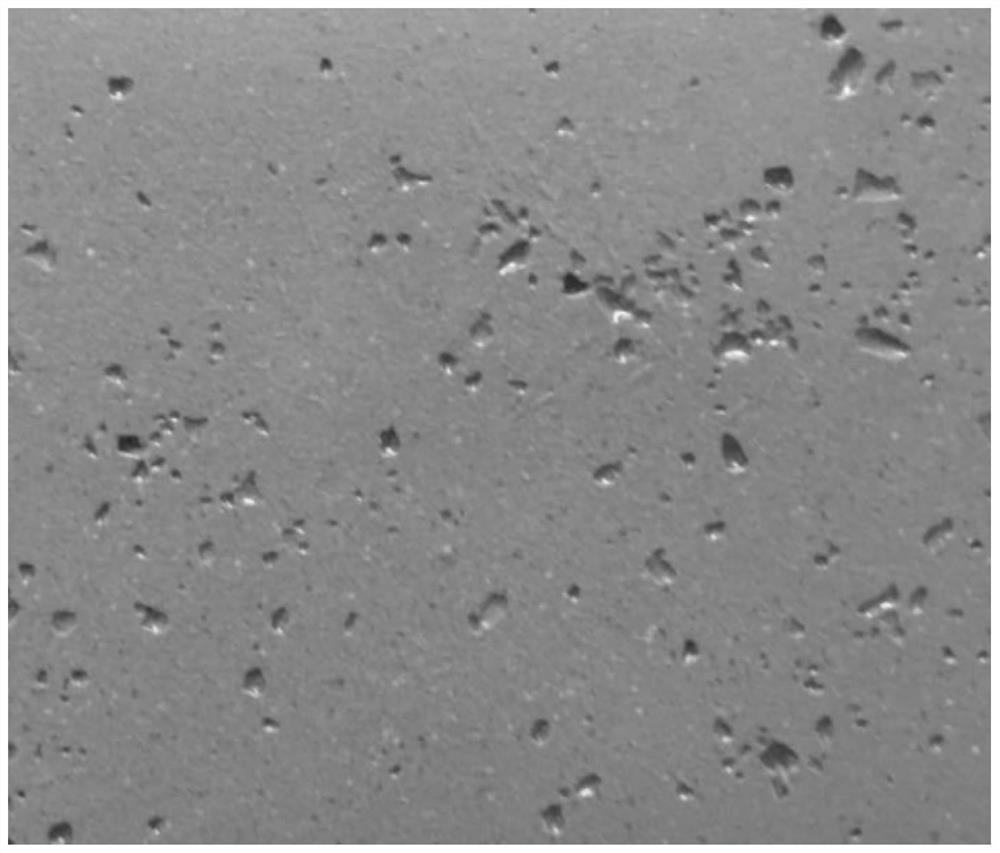

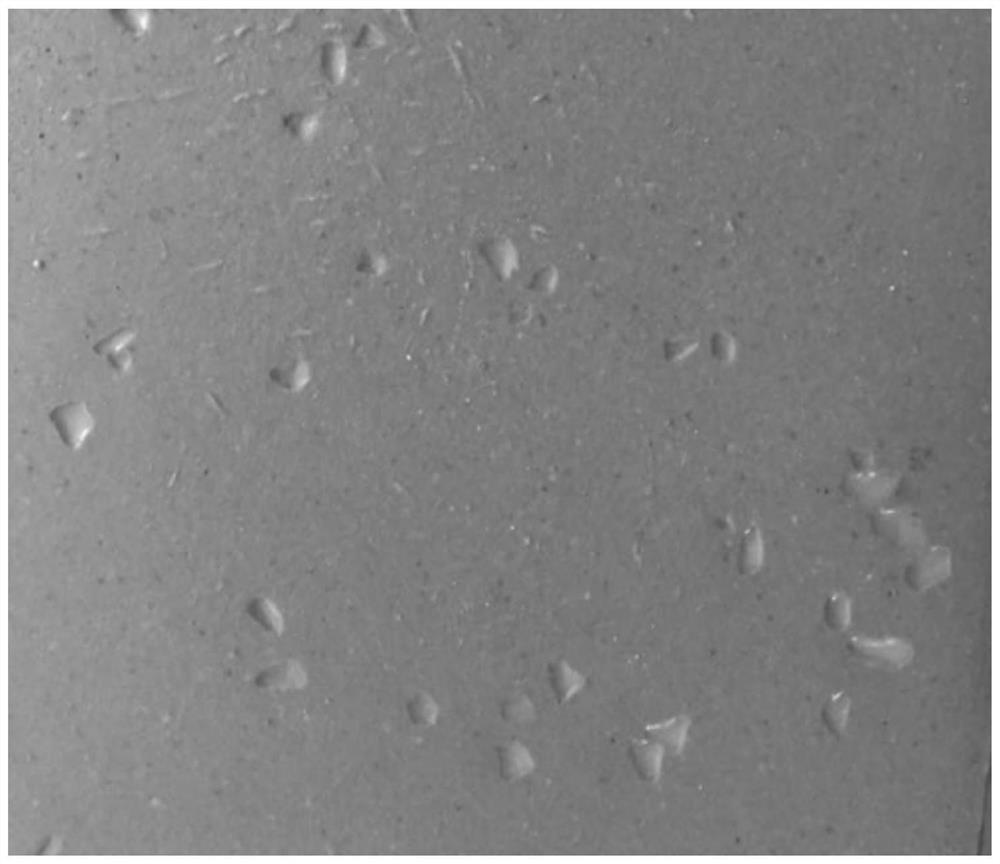

Image

Examples

preparation example Construction

[0027] A method for preparing semi-permeable travertine dry granule bricks, comprising distributing the above-mentioned semi-permeable travertine dry granules on a glaze layer and firing them.

[0028] As a further improvement of the above preparation method, the firing temperature of the dry semi-permeable travertine brick is 1180°C to 1230°C.

Embodiment 1

[0032] Semi-permeable travertine dry granules, its raw material composition is: 30 parts of feldspar, 35 parts of limestone, 5 parts of ball soil, 20 parts of flour, and 20 parts of walnut shell powder. After granulation, it is dried until the moisture content is 4-7%, and the particle gradation of the dry granules is 10-60 mesh.

Embodiment 2

[0034] Semi-permeable travertine dry granules, its raw materials are composed of 35 parts of feldspar, 35 parts of limestone, 5 parts of ball soil, 25 parts of flour, and 10 parts of walnut shell powder. After granulation, it is dried until the moisture content is 4-7%, and the particle gradation of the dry granules is 10-60 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com