A blade processing system and method on an integral blisk

A technology of integral blisks and processing systems, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of blade processing accuracy and surface quality that are difficult to guarantee, so as to improve automation and intelligence capabilities and solve processing problems. The effect of high precision requirements and reduced process preparation and operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

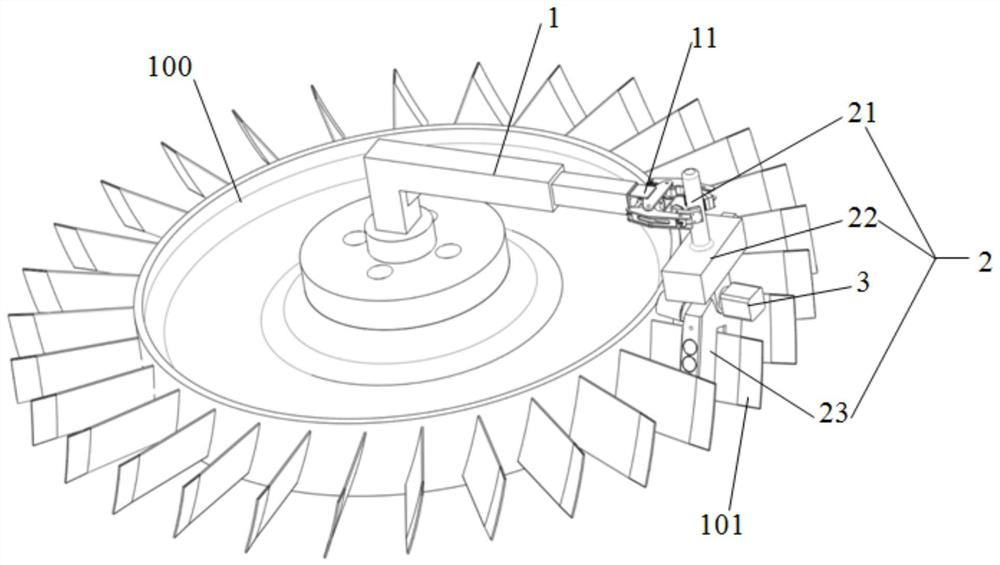

[0032] Embodiment 1 provides a blade processing system on a blisk, which processes blades 101 of a blisk 100 to be processed, and its structure will be described in detail below.

[0033] refer to Figure 1 to Figure 3 , the blade processing system on the integral blisk includes a blisk fixture 1, a blade clamping device 2, a servo motor 3, a numerical control machine tool, an intelligent numerical control module and a machining process knowledge base interface.

[0034] The fixed end of the blisk clamp 1 is used to be fixed to the center of the blisk 100, and the free end of the blisk clamp 1 is provided with a docking rod clamp 11;

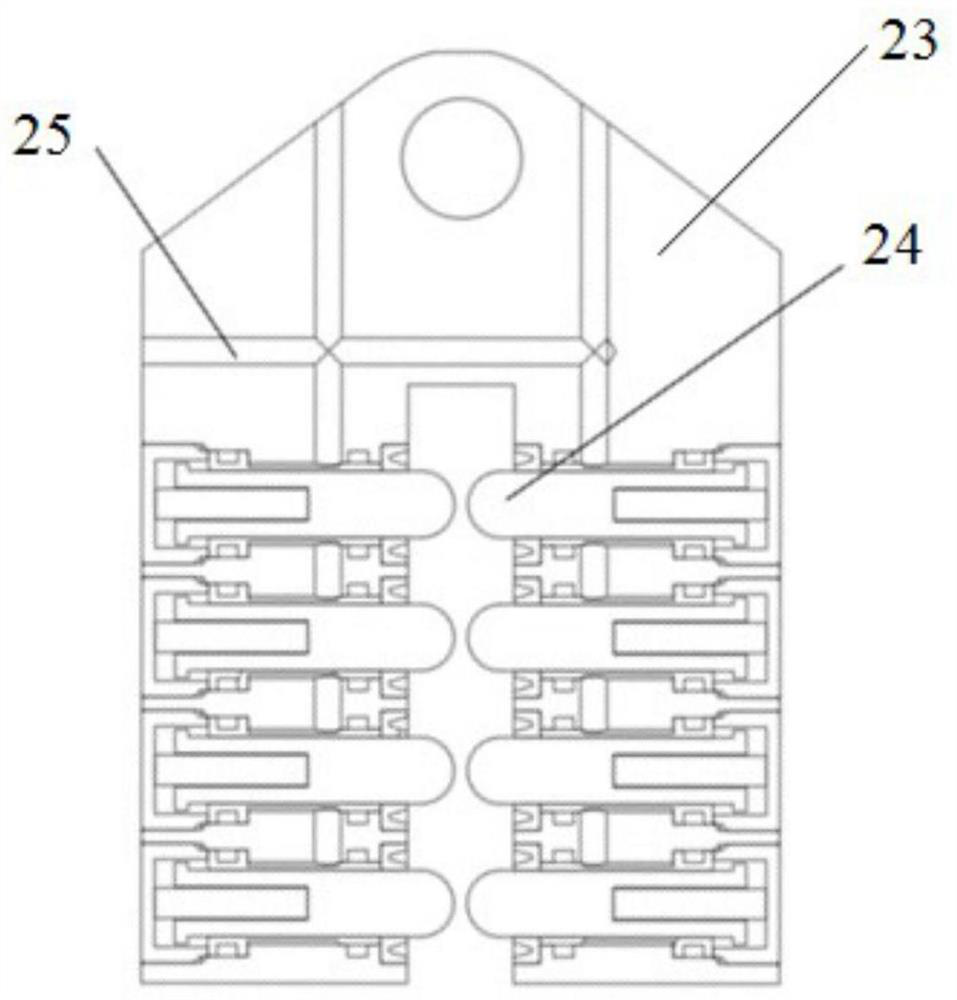

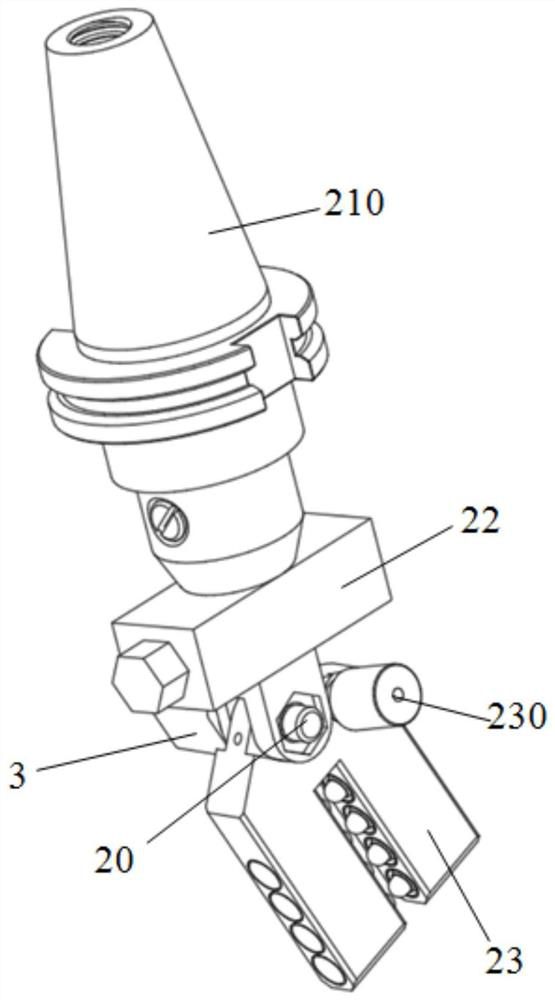

[0035] The blade clamping device 2 includes a docking rod 21, a hydraulic oil conveyor 22, and a blade clamping mechanism 23, and the docking rod 21 and the blade clamping mechanism 23 are respectively arranged on both sides of the hydraulic oil conveyor 22 , and the hydraulic oil conveyor 22 and the blade clamping mechanism 23 are connected th...

Embodiment 2

[0061] Embodiment 2 provides a blade processing method on the blisk, using the blade processing system on the blisk provided in embodiment 1, the method includes the following steps:

[0062] Step S1: installing the blisk 100 on the workbench of the CNC machine tool;

[0063] Step S2: Install the fixed end of the blisk fixture 1 on the center of the blisk 100, and position and fix the blisk 100;

[0064] Step S3: Select the blade 101 to be processed on the blisk 100 on the blisk 100, and control the rotation of the blisk 100 through a numerical control machine tool, so that the blade 101 to be processed reaches a predetermined initial position;

[0065] Step S4: Start the spindle of the CNC machine tool, the spindle of the CNC machine tool starts to move, transport the blade clamping device 2 to the position of the blade 101 to be processed through the CNC machine tool quick connection device 210, start the servo motor 3, and drive the blade clamping mechanism 23 rotates arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com