Vegetable dehydration equipment

A vegetable dehydration and equipment technology, applied in the fields of application, food science, food processing, etc., can solve the problems of incomplete dehydration and difficult cleaning of fillings, and achieve the effects of improving dehydration efficiency, preventing reabsorption of water, and reducing eccentric force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

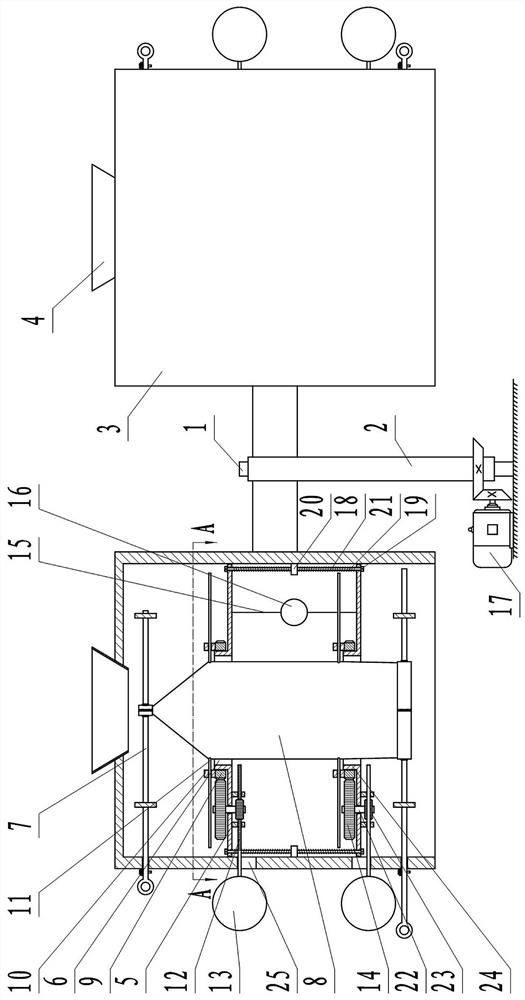

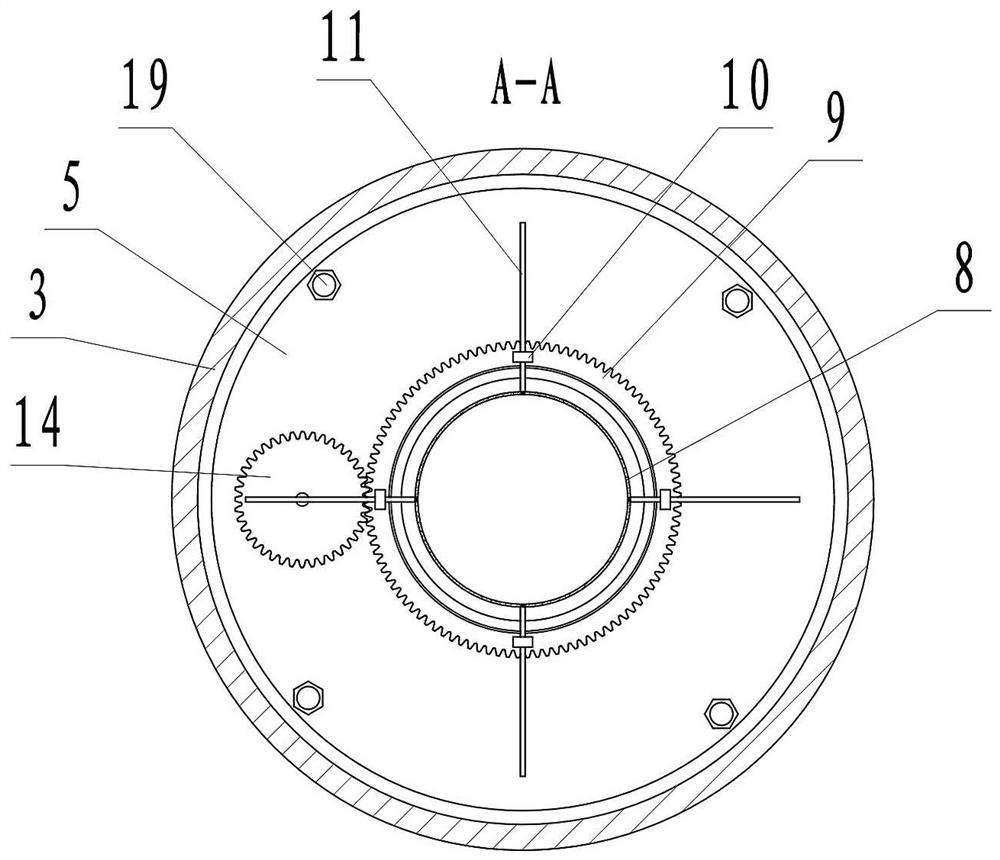

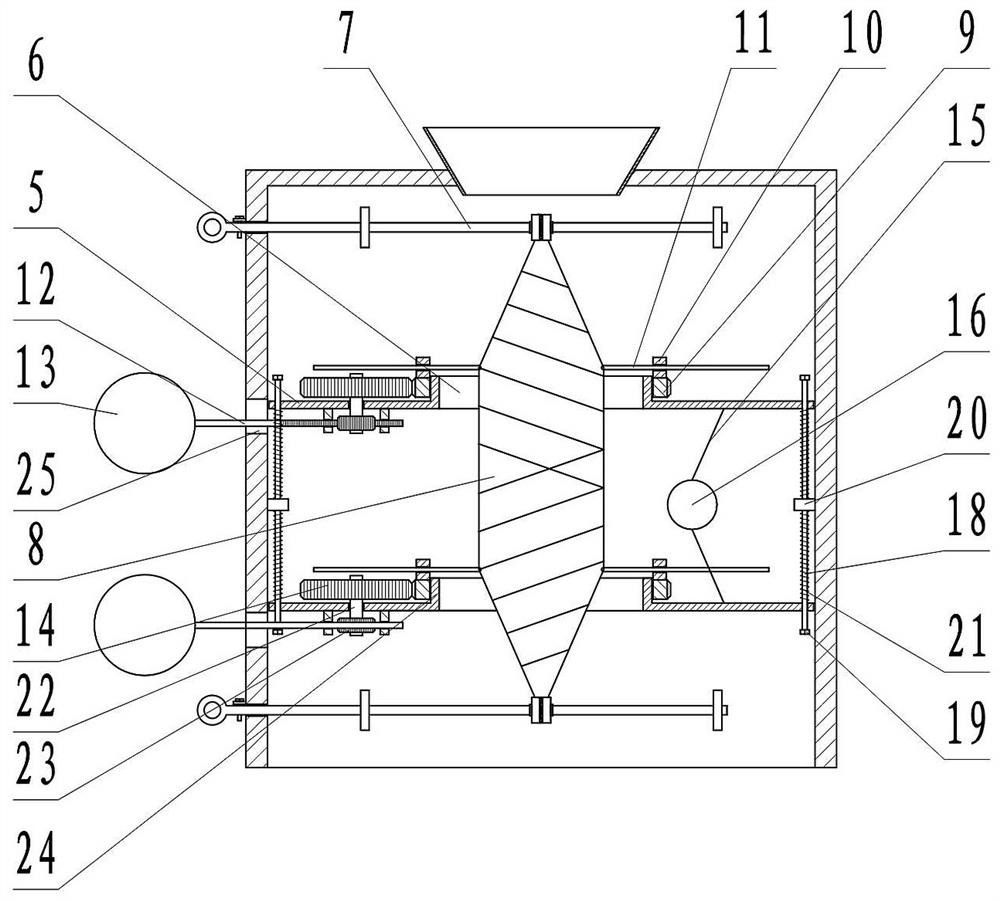

[0023] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Depend on Figure 1 to Figure 4 Given, the present invention includes a vertical support rod 1, the support rod 1 is covered with a rotatable sleeve 2, and the outer circumference of the sleeve 2 is fixed with a plurality of boxes 3; the lower end of the box 3 is open, and the upper end is provided with a feeding port 4; each box body 3 is provided with two upper and lower support plates 5, and the two support plates 5 can move up and down and reset; the middle part of the support plate 5 has a central hole 6, and the upper and lower parts of the box body 3 are respectively installed There is a sealing device 7, and a cloth bag 8 connecting up and down is installed between the upper and lower sealing devices 7. The upper and lower ends of the cloth bag 8 are respectively connected to the upper and lower sealing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com