Preparation method of photoelectrochemical sensor for detecting in-situ ratio of Cry1Ab protein in transgenic crop

A photoelectrochemical and sensor technology, which is applied in the field of biosensors, can solve the problems of small semiconductor band gaps, etc., and achieve the effect of improving selectivity, reducing interference, and increasing electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

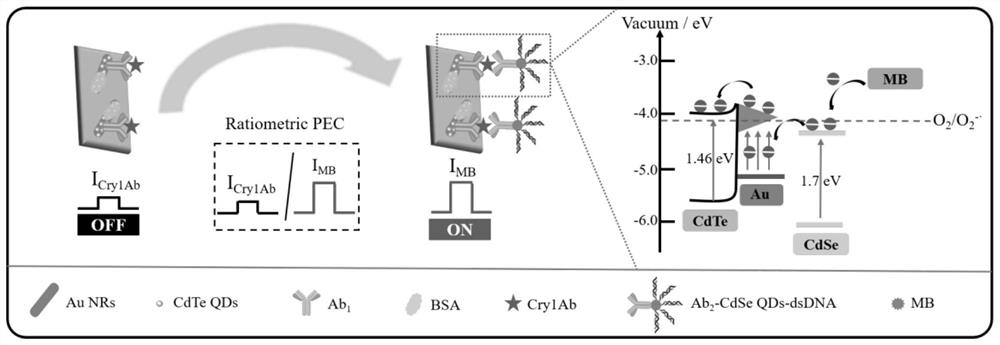

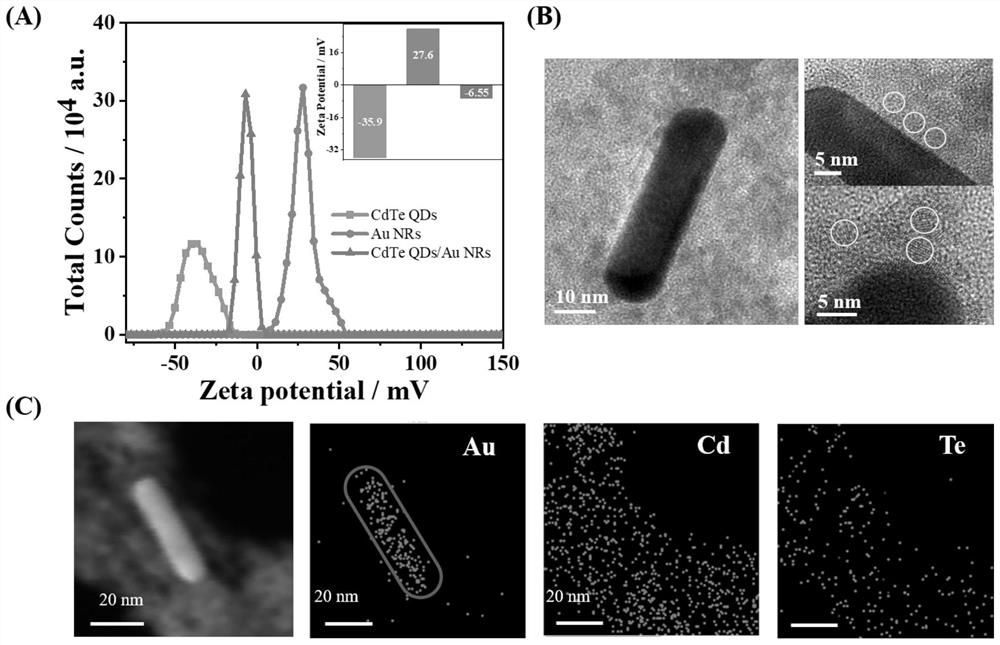

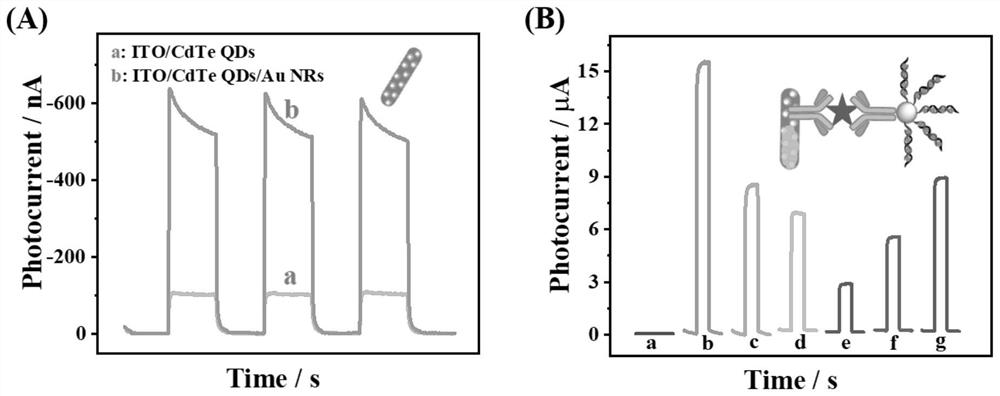

[0047] according to figure 1 Described preparation process:

[0048] (1) Preparation of Au NRs nanomaterials:

[0049] Au NRs were prepared using a seed-mediated growth method. First, 4.5mL H 2 O, 5 mL 0.2M CTAB solution, 500 μL 5 mM HAuCl 4 solution and 610 μL of 10 mM NaBH on ice 4 The solution is mixed. After stirring for 2 min, the mixture was allowed to react undisturbed for 2 h at 30 °C to obtain a gold seed solution. Then, 24mL 0.2M CTAB, 4.8mL 5mM HAuCl 4 solution, 50 μL 0.1M AgNO 3 solution, 32 μL of 1.2M HCl and 2.8 mL of 10 mM ascorbic acid solution were mixed in a 50 mL vial, and then 48 μL of the seed solution was added. The resulting solution was gently stirred for 15 s and left undisturbed for 20 h. The color of the solution changed from colorless to brick red, indicating the formation of Au NRs.

[0050] (2) Preparation of CdTe QDs nanomaterials:

[0051] CdTe QDs were synthesized using a hydrothermal method. First, synthesize the fresh precursor sod...

Embodiment 2

[0066] (1) Preparation of Au NRs nanomaterials:

[0067] Au NRs were prepared using a seed-mediated growth method. First, 4.5mL H 2 O, 5 mL 0.2M CTAB solution, 500 μL 5 mM HAuCl 4 solution and 610 μL of 10 mM NaBH on ice 4 The solution is mixed. After stirring for 2 min, the mixture was allowed to react undisturbed for 2 h at 30 °C to obtain a gold seed solution. Then, 24mL 0.2M CTAB, 4.8mL 5mM HAuCl 4 solution, 50 μL 0.1M AgNO 3 solution, 32 μL of 1.2M HCl and 2.8 mL of 10 mM ascorbic acid solution were mixed in a 50 mL vial, and then 48 μL of the seed solution was added. The resulting solution was gently stirred for 15 s and left undisturbed for 20 h. The color of the solution changed from colorless to brick red, indicating the formation of Au NRs.

[0068] (2) Preparation of CdTe QDs nanomaterials:

[0069] CdTe QDs were synthesized using a hydrothermal method. First, synthesize the fresh precursor sodium tellurium hydride (NaHTe): add 0.0638g tellurium powder and ...

Embodiment 3

[0084] (1) Preparation of Au NRs nanomaterials:

[0085] Au NRs were prepared using a seed-mediated growth method. First, 4.5mL H 2 O, 5 mL 0.2M CTAB solution, 500 μL 5 mM HAuCl 4 solution and 610 μL of 10 mM NaBH on ice 4 The solution is mixed. After stirring for 2 min, the mixture was allowed to react undisturbed for 2 h at 30 °C to obtain a gold seed solution. Then, 24mL 0.2M CTAB, 4.8mL 5mM HAuCl 4 solution, 50 μL 0.1M AgNO 3 solution, 32 μL of 1.2M HCl and 2.8 mL of 10 mM ascorbic acid solution were mixed in a 50 mL vial, and then 48 μL of the seed solution was added. The resulting solution was gently stirred for 15 s and left undisturbed for 20 h. The color of the solution changed from colorless to brick red, indicating the formation of Au NRs.

[0086] (2) Preparation of CdTe QDs nanomaterials:

[0087] CdTe QDs were synthesized using a hydrothermal method. First, synthesize the fresh precursor sodium tellurium hydride (NaHTe): add 0.0638g tellurium powder and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com