Electrochemical test device for simulating buried pipeline steel stress corrosion under acid rain leaching condition

A technology of stress corrosion and testing equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, and the use of repeated force/pulsation force to test the strength of materials, etc., which can solve the problems of less research on biological factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

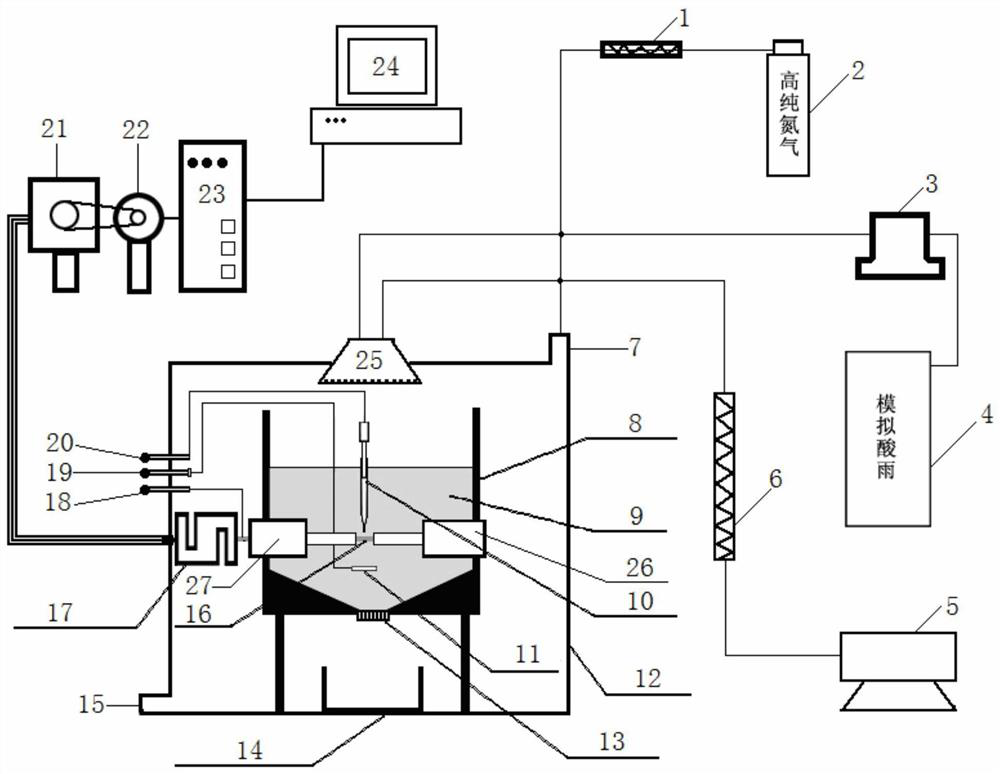

[0018] Such as figure 1 As shown, the electrochemical test device for stress corrosion of buried pipeline steel under simulated acid rain leaching conditions of the present invention mainly includes: gas purification device 1, high-purity nitrogen cylinder 2, constant flow pump 3, simulated acid rain box 4, compressor 5 , Gas purification device 2 6, air inlet 7, test chamber 8, soil 9, reference electrode 10, Pt electrode 11, anaerobic box 12, filter funnel 13, filtrate receiver 14, gas outlet 15, pipeline steel electrode 16 , weighing sensor 17, WE terminal 18, CE terminal 19, RE terminal 20, worm gear reducer 21, stepper motor 22, control box 23, computer 24, nozzle 25, etc. The specific structure is as follows:

[0019] Test box 8 and filtrate receiver 14 are arranged in anaerobic box 12, and filtrate receiver 14 is positioned at the bottom of test box 8, and nozzle 25 is installed in the middle of the top of anaerobic box 12, and nozzle 25 is positioned at the top of test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com