Dynamic membrane forming control method applicable to anaerobic digestion of excess sludge

A technology of excess sludge and anaerobic digestion, applied in sludge treatment, biological sludge treatment, waste fuel, etc., can solve problems such as poor solid-liquid separation effect, damage to dynamic membrane, high replacement cost, etc., and achieve gas saving The effect of recycling energy consumption, reducing damage, and facilitating upgrading and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

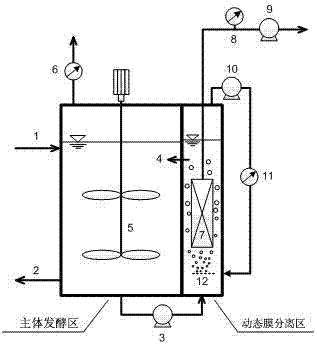

[0024] use figure 1 The process shown treats residual sludge from municipal sewage treatment plants. It is composed of the main fermentation area and the dynamic membrane separation area, of which the effective volume of the latter is only 3% of the former. The main fermentation area is equipped with a mud inlet pipe 1, a mud discharge pipe 2, a stirring device 5 and a gas metering device 6; the dynamic membrane separation area is equipped with a dynamic membrane module 7, a pressure gauge 8, an outlet pump 9 and a biogas circulation system. The circulation system is composed of a diaphragm vacuum pump 10, a gas flow meter 11 and a biogas diffusion pipe 12; the two areas are connected by a sludge return pump 3 and a sludge return pipe 4. The remaining sludge enters the reactor system from the sludge inlet pipe 1, and is stirred and mixed by the stirring device 5 in the main fermentation area; the sludge in the main fermentation area enters the dynamic membrane separation area...

Embodiment 2

[0027] use figure 1 The process shown treats residual sludge from municipal sewage treatment plants. Inlet sludge concentration (MLSS) is 5-8 g / L, and sludge concentration (MLSS) in the dynamic membrane separation zone is 18-22 g / L. The dynamic membrane module 7 adopts a polyester mesh module with a pore size of 39 μm and a membrane area of 0.038 m 2 , the membrane flux is 15 L / (m 2 · h), using continuous membrane filtration to operate. Using the invented method to operate, in a biogas cycle cycle, the closing time of the biogas circulation is 20 minutes, the opening time is 3 minutes, and the biogas circulation intensity is 25 m 3 / (m 2 h). The turbidity of the effluent is less than 150 NTU, the MLSS of the effluent is less than 120 mg / L, and the physical cleaning cycle of the dynamic membrane module is 5-10 days.

Embodiment 3

[0029] use figure 1 The process shown treats residual sludge from municipal sewage treatment plants. Inlet sludge concentration (MLSS) is 5-8 g / L, and sludge concentration (MLSS) in the dynamic membrane separation zone is 18-22 g / L. The dynamic membrane module 7 adopts a polyester mesh module with a pore size of 39 μm and a membrane area of 0.038 m 2 , the membrane flux is 15 L / (m 2 · h), using continuous membrane filtration to operate. Using the invented method to operate, in a biogas cycle cycle, the closing time of the biogas circulation is 20 minutes, the opening time is 1 minute, and the biogas circulation intensity is 50 m 3 / (m 2 h). The turbidity of the effluent is less than 160 NTU, the MLSS of the effluent is less than 140 mg / L, and the physical cleaning cycle of the dynamic membrane module is 7-20 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com