Air compressor unloading device and electromagnetic valve adopting same

An unloading device, air compressor technology, applied in mechanical equipment, machinery/engine, liquid variable capacity machinery, etc. Long service life, preventing start-up with load, good exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

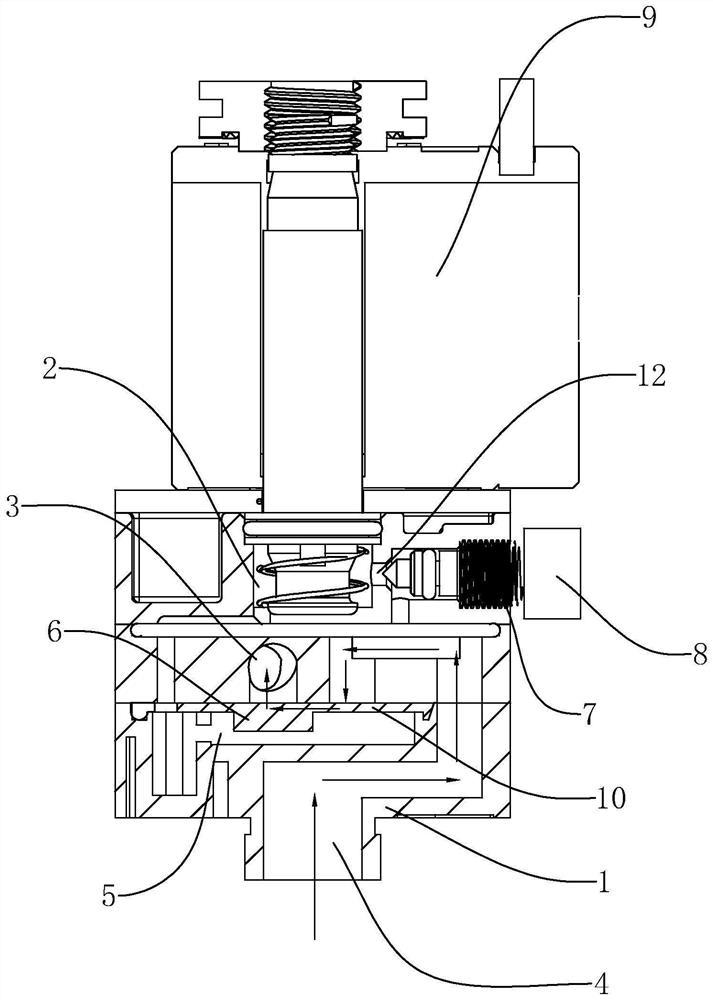

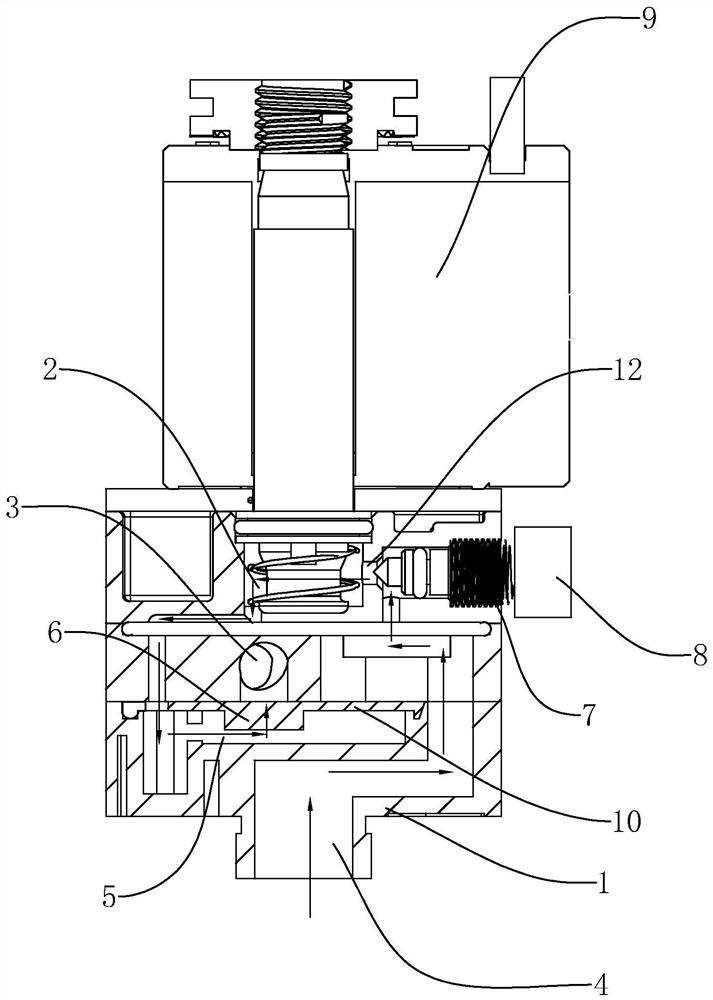

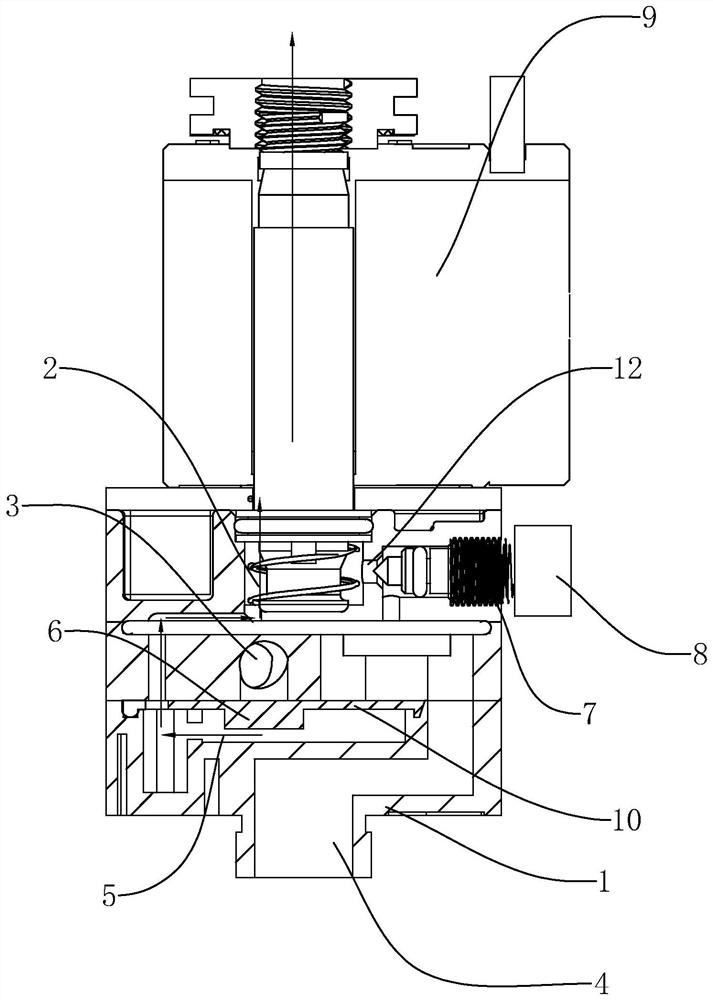

[0021] Such as Figure 1-6 As shown, an air compressor unloading device includes a base 1, and the base 1 is provided with a cavity 2 that can be matched with a solenoid valve 9, and the base 1 is provided with at least one unloading hole 3 and an exhaust port. The intake flow channel 4 connected by the pipe, the intake flow channel 4 communicates with at least one unloading hole 3 to form the first unloading channel (the gas path of the first unloading channel can be found in figure 1 Arrow), the base 1 also has a built-in communication cavity 5, which communicates with the cavity 2, the unloading hole 3, and the air intake channel 4 respectively, and the communication cavity 5 has a built-in device that can conduct or block the first The gasket 6 of the unloading passage, one side of the gasket 6 is provided with a pressure receiving part 10 that can separate the intake flow channel 4 from the communication cavity 5, and the pressure receiving part 10 is provided with a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com