A new type of automatic unloading device for accumulators of explosion-proof vehicles in coal mines

An explosion-proof vehicle, automatic unloading technology, applied in actuator accumulators, fluid pressure actuating devices, servo motor components, etc., can solve problems such as safety production accidents, achieve automatic unloading, ensure personal safety, ensure The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

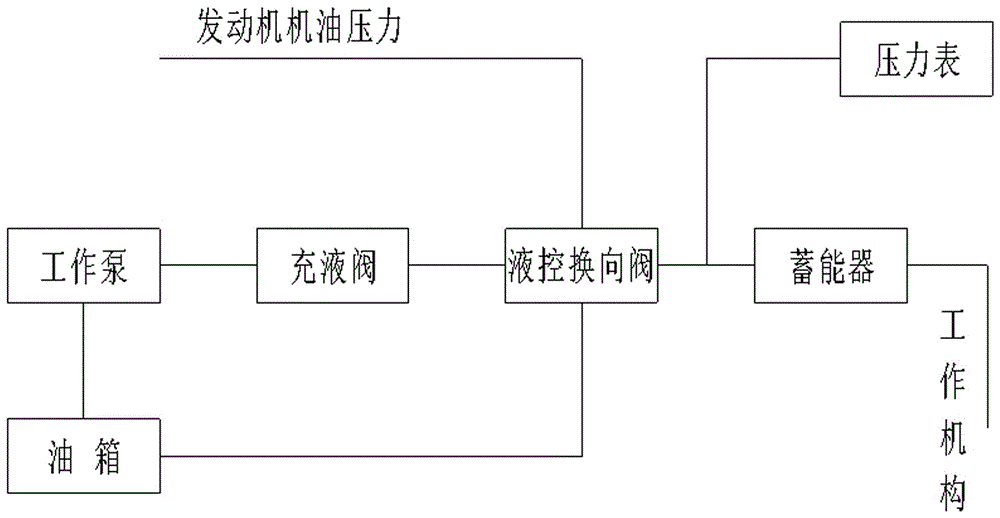

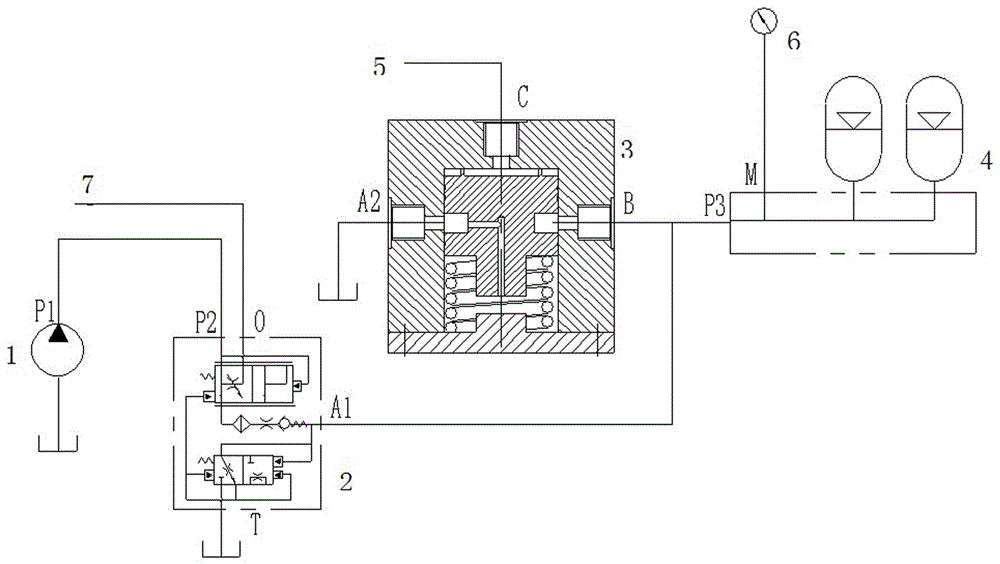

[0017] A novel accumulator automatic unloading device for explosion-proof vehicles in coal mines, comprising a fuel tank, a working pump 1, a liquid filling valve 2, a hydraulic control reversing valve 3 and an accumulator 4 connected in sequence.

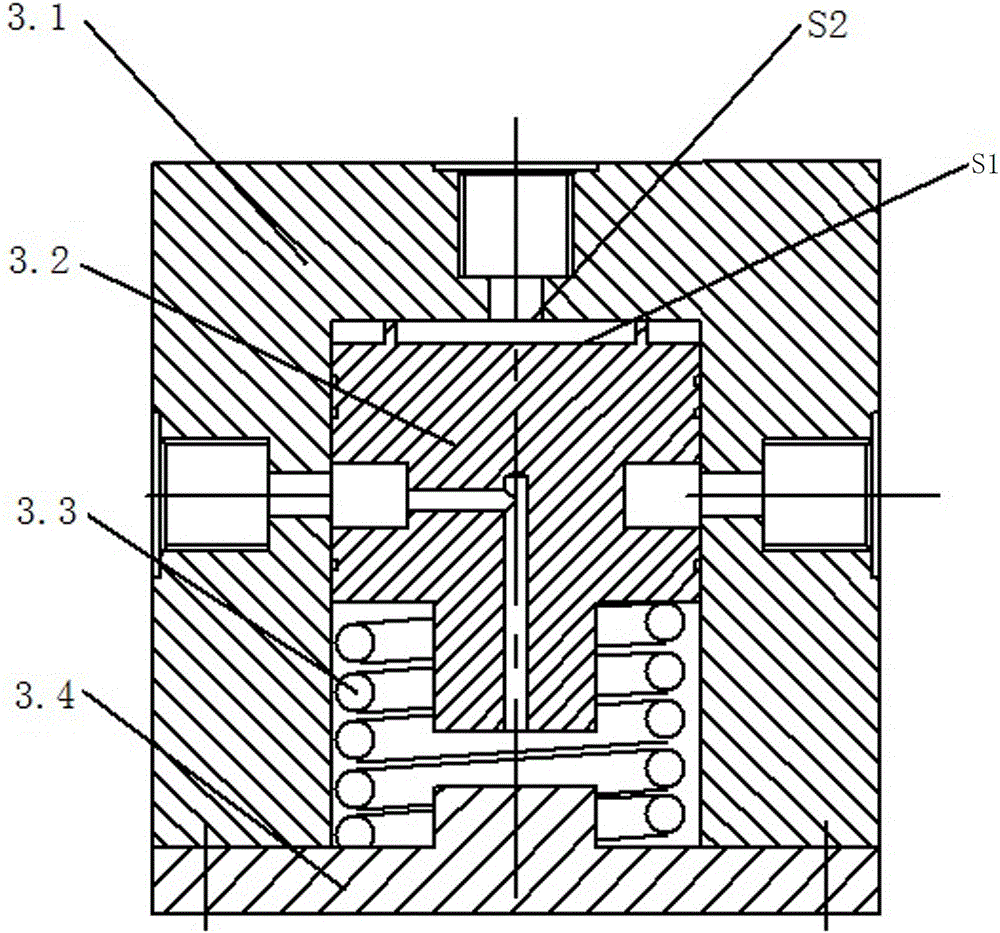

[0018] Such as figure 2 As shown, the hydraulic control reversing valve includes a valve body 3.1, a valve core 3.2, a cover plate 3.4, and a spring 3.3. The valve body 3.1 has a cavity to install the valve core 3.2, and the bottom of the valve body 3.1 is installed with a cover plate 3.4 to seal the cavity. , the bottom of the spool 3.2 is connected to one end of the spring 3.3, the other end of the spring 3.3 is connected to the cover plate 3.4, the spool 3.2 has an annular groove along the circumferential direction, and a through hole is opened from the annular groove to the bottom of the spool, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com