A screw compressor fault diagnosis method and system

A screw compressor and fault judgment technology, applied in the direction of machine/engine, etc., can solve the problems of the braking system supplying compressed air, the inability to ensure the effectiveness of the braking force of locomotives and vehicles, and the loss of wind blowing ability, so as to ensure safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

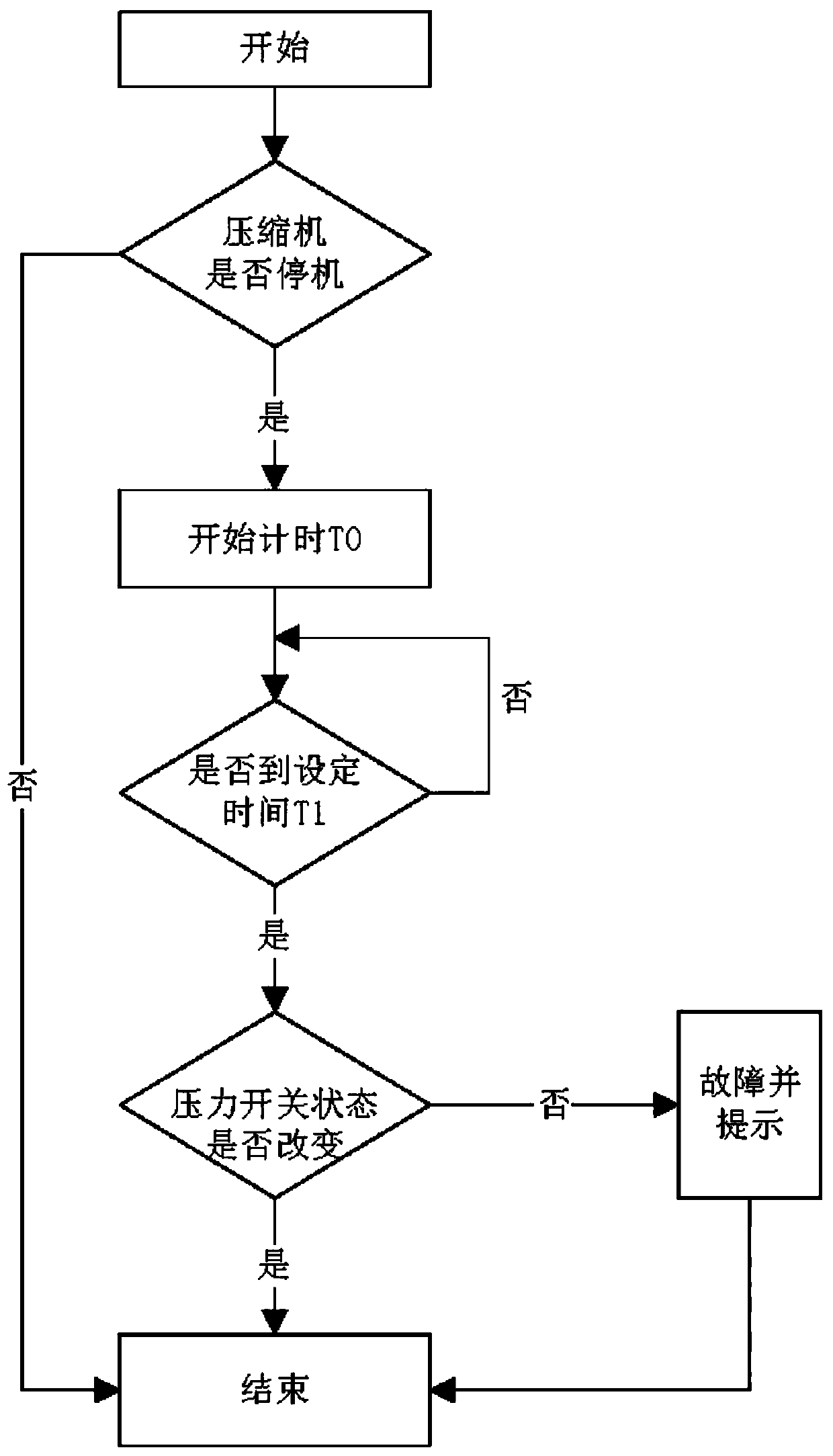

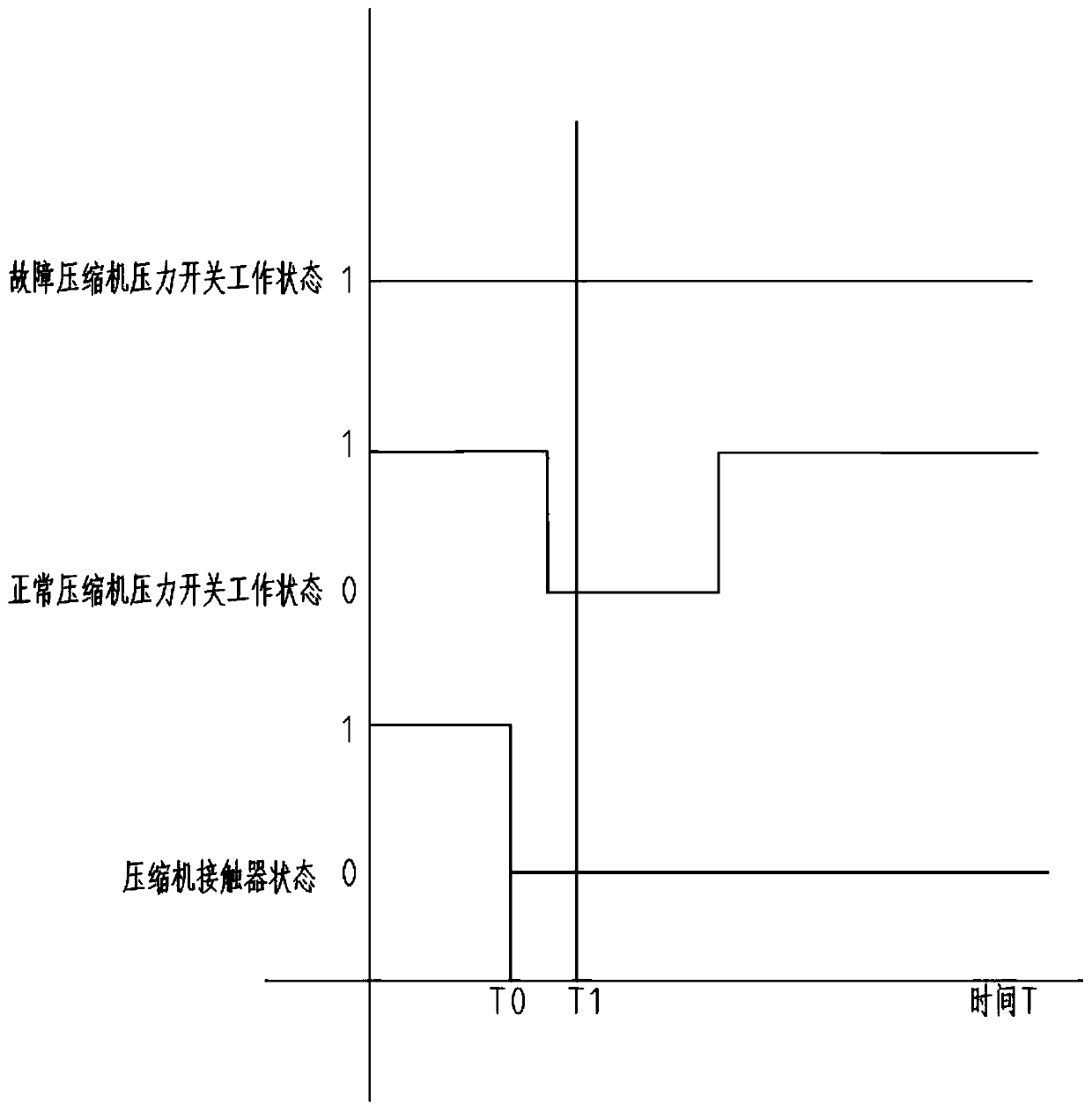

[0025] The flow chart of the fault judgment method is attached figure 1 , the comparison chart of the pressure switch status under normal and fault status is shown in the attachment figure 2 .

[0026] Screw compressor failure judgment method of the present invention comprises the following steps:

[0027] Step A, monitor whether the screw compressor is shut down, and jump to step B if the screw compressor is shut down;

[0028] Step B: From the moment the screw compressor stops, after a set period of time, check whether the normally closed contact of the pressure switch is disconnected. If the normally closed contact of the pressure switch is not disconnected, it is judged that the screw compressor is faulty. When the screw compressor fails, the fault status is sent to the driver's cab for display.

[0029] In step A, determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com