Oil circuit quick change joint concentric single interface structure

A single interface, oil circuit technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of automatic connection of high and low pressure oil circuits, high labor intensity, and singleness, so as to avoid energy waste and reduce labor intensity , to ensure the effect of timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

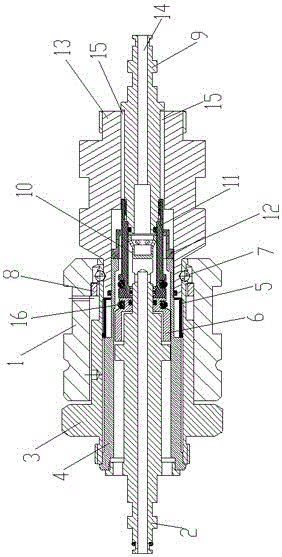

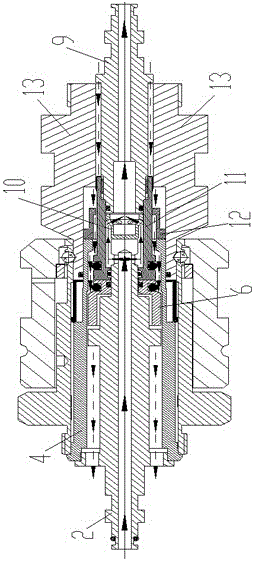

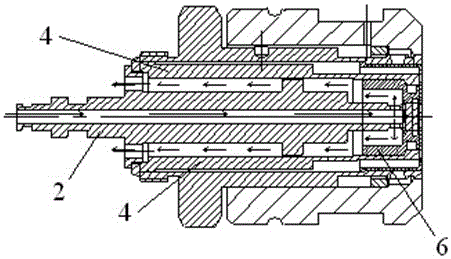

[0015] Such as figure 1 , figure 2 with image 3 As shown, a concentric single-interface structure of an oil circuit quick change joint, including a female joint and a male joint. The movable overcoat 5 and the movable inner sleeve 6 of the vaginal opening are composed of a reset spring 16 arranged on the movable inner sleeve 6 of the female opening. The sleeve 6 is arranged between the female opening core 2 and the female opening fixed inner sleeve 4, and the female opening movable overcoat 5 is arranged between the female opening fixed inner sleeve 4 and the female opening fixed outer sleeve 3; the male joint is mainly composed of a ring core 9 , a first-ring movable cap 10, a second-ring fixed sleeve 11, a third-ring movable sleeve 12 and a fourth-ring fixed sleeve 13, the front end of the first-ring core 9 is connected to the female mouth core 2 of the female connector through the first-ring movable cap 10, The second ring fixed sleeve 11 is clamped on the front part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com