High-purity tantalum rotating target material and preparation method thereof

A rotating target, high-purity technology, applied in metal processing equipment, metal material coating process, ion implantation plating, etc. Uniform and controllable layer thickness, high purity, and low process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a high-purity tantalum rotating target, which includes the following steps: using an induction plasma spheroidization process to prepare high-purity spherical tantalum powder, and then using the high-purity spherical tantalum powder as a spraying raw material, using low-pressure plasma The spraying process prepares a high-purity tantalum coating on the surface of the rotating substrate, thereby producing a high-purity tantalum rotating target.

[0032] Specifically, the preparation method of the high-purity tantalum rotating target may include the following:

[0033] (1) The high-purity spherical tantalum powder prepared by the induction plasma spheroidization process includes: the original tantalum powder with a particle size of 25-45 μm, a purity ≥ 99.99%, and an oxygen content ≤ 300ppm (the original tantalum powder refers to the existing tantalum powder. In the prior art, tantalum powder which can be obtained by commercia...

Embodiment 1

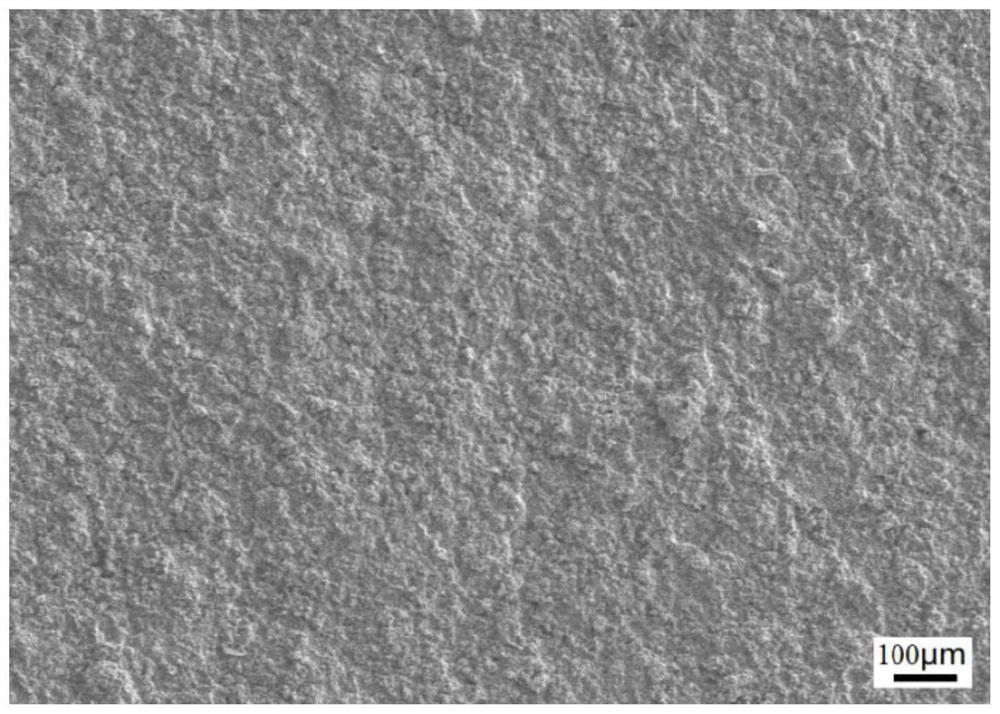

[0043] like figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of high-purity tantalum rotating target material, its preparation method comprises the following steps:

[0044] Step 1. The original tantalum powder with a particle size of 25-45 μm, a purity of 99.99%, and an oxygen content of 280 ppm (the original tantalum powder is the tantalum powder before the induction plasma spheroidization process, and its appearance is as follows: figure 1 Shown in A) as the feed material, the original powder is processed by induction plasma spheroidization process, the hydrogen flow rate is controlled to 80slpm, the plasma power is 80kW, the carrier gas flow rate is 5slpm, the argon flow rate is 90slpm, and the powder feeding rate is 50g / min, and then ultrasonically cleaned and dried to prepare high-purity spherical tantalum powder (the high-purity spherical tantalum powder is the tantalum powder after the induction plasma spheroidization process, and its appearance is as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com