A preparation method of microcapsules for controlling cement hydration heat for low temperature well cementing

A technology of cement hydration and microcapsules, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of low phase transition temperature, insensitive temperature response, and high phase transition point temperature of paraffin wax materials, and achieve good compatibility, Reduce the discharge of heat of hydration to the outside and realize the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

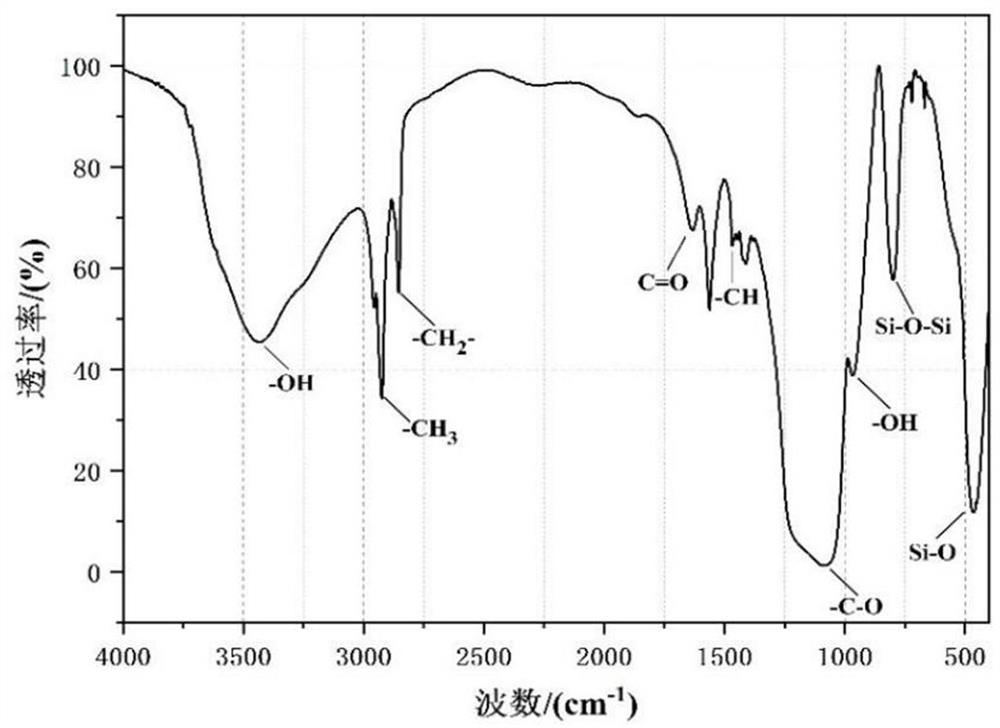

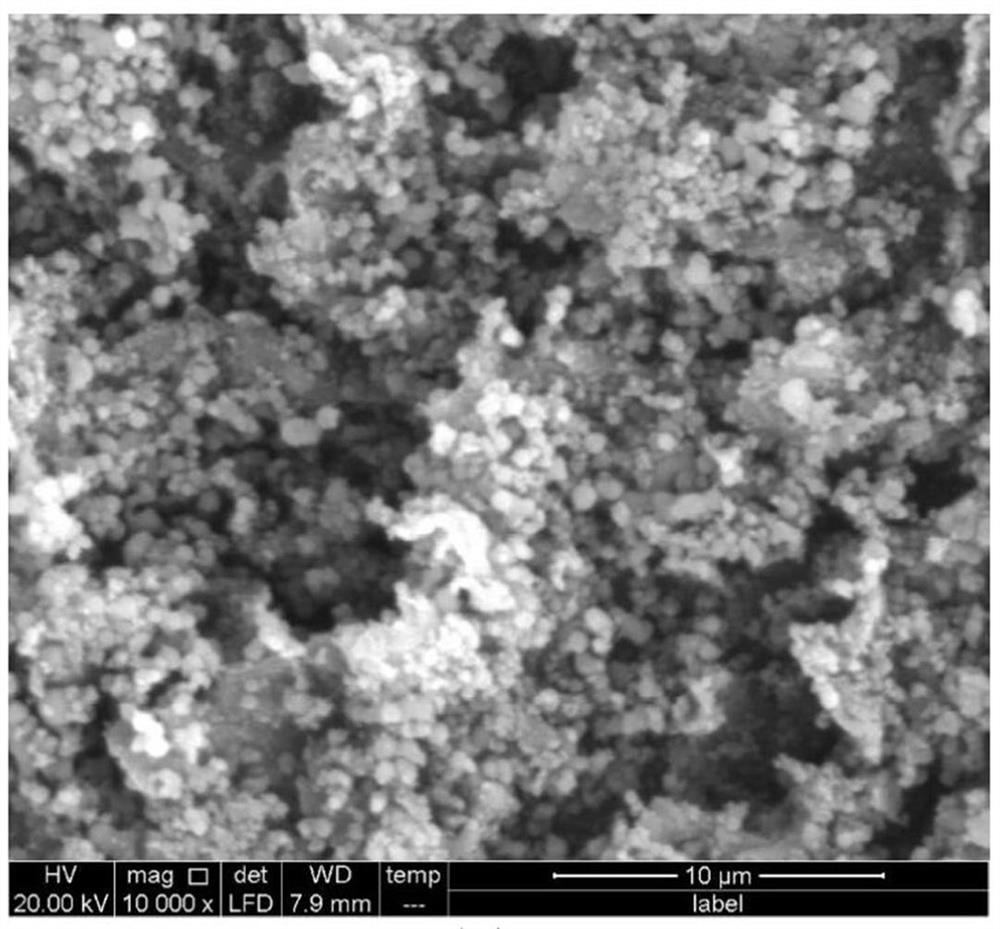

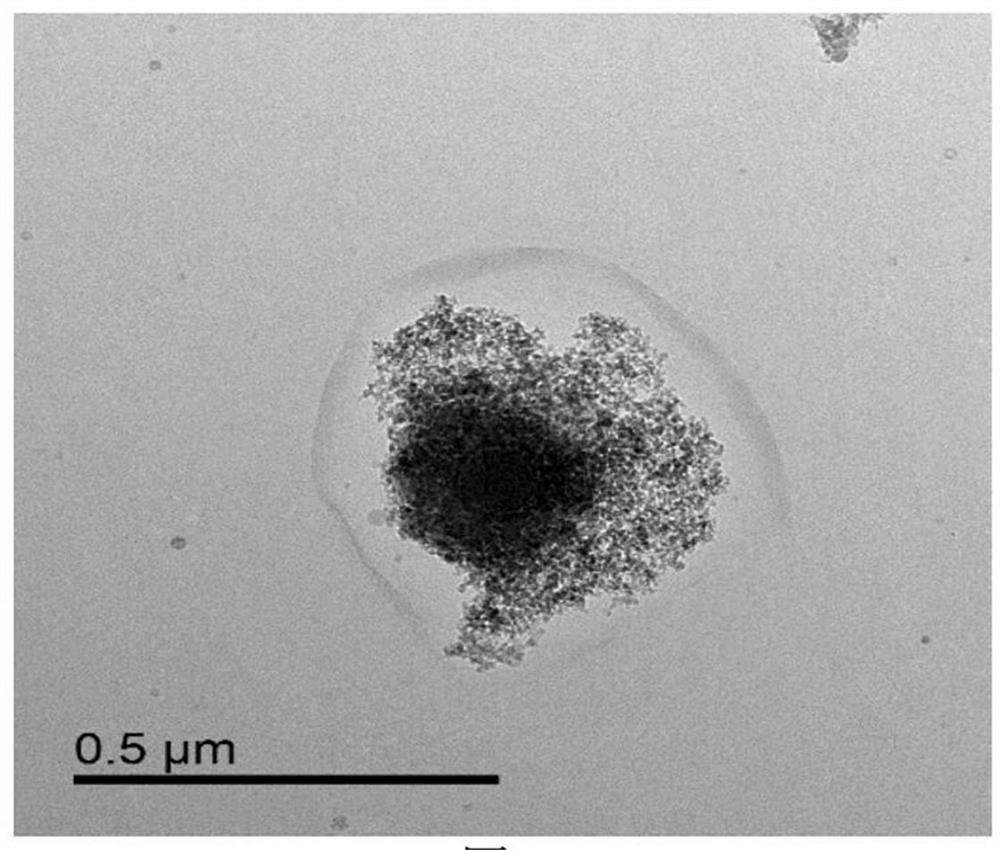

[0034] Weigh 10 g of sodium silicate, add it into 50 mL of deionized water at 45°C and stir magnetically for 10 min to dissolve it completely. Add 5g lauryl alcohol and 5g n-capric acid mixed solution, 0.05g CTBA and 0.05g OP-10 into a three-necked flask, keep heating in a water bath at 45°C, stir with a stirrer at a speed of 2000rpm for 30min, so that lauryl alcohol and n-capric acid are evenly dispersed And form an oil-in-water (O / W) emulsion, and add hydrochloric acid to adjust the pH value to 1.5. Transfer the above emulsion to a 50°C constant temperature water bath, and at the same time, add the prepared sodium silicate solution dropwise into the three-necked flask with a separatory funnel, and stir at a speed of 300rpm for 2h, then transfer the product to a beaker to naturally Cool to room temperature, filter with suction, wash with absolute ethanol and deionized water, and freeze-dry.

Embodiment 2

[0036]Weigh 12g of sodium silicate, add it into 80mL of deionized water at 45°C and stir magnetically for 10min to dissolve it completely. Add 6g of lauryl alcohol and 6g of n-capric acid mixed solution, 0.03g of CTBA and 0.07g of OP-10 into a three-necked flask, keep heating in a water bath at 45°C, stir with a stirrer at a speed of 2000rpm for 30min, so that lauryl alcohol and n-capric acid are evenly dispersed And form an oil-in-water (O / W) emulsion, and add hydrochloric acid to adjust the pH value to 2. The above emulsion was transferred to a 60°C constant temperature water bath, and at the same time, the prepared sodium silicate solution was added dropwise into the three-neck flask with a separatory funnel, and stirred at a speed of 500rpm for 2h, and then the product was transferred to a beaker and naturally Cool to room temperature, filter with suction, wash with absolute ethanol and deionized water, and freeze-dry.

Embodiment 3

[0038] Weigh 15g of sodium silicate, add it into 50mL of deionized water at 45°C and stir magnetically for 10min to dissolve it completely. Add 7g lauryl alcohol and 7g n-capric acid mixed solution, 0.02g CTBA and 0.08g OP-10 into a three-necked flask, keep heating in a water bath at 45°C, stir with a stirrer at a speed of 2000rpm for 30min, so that lauryl alcohol and n-capric acid are evenly dispersed And form an oil-in-water (O / W) emulsion, and add hydrochloric acid to adjust the pH value to 2.5. Transfer the above emulsion to a 70°C constant temperature water bath, and at the same time, add the prepared sodium silicate solution dropwise into the three-necked flask with a separatory funnel, and stir at a speed of 600rpm for 2.5h, and then transfer the product into a beaker Naturally cooled to room temperature, suction filtered, washed with absolute ethanol and deionized water, and freeze-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com