Wireless passive temperature sensing system for auxiliary converter cabinet of electric locomotive

An electric locomotive, wireless passive technology, applied in the field of temperature sensing, can solve problems such as limited detection area, easy breakage of optical fiber, complex wiring, etc., achieve excellent resistance to high voltage and electromagnetic radiation, wide operating temperature range, and avoid chemical leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

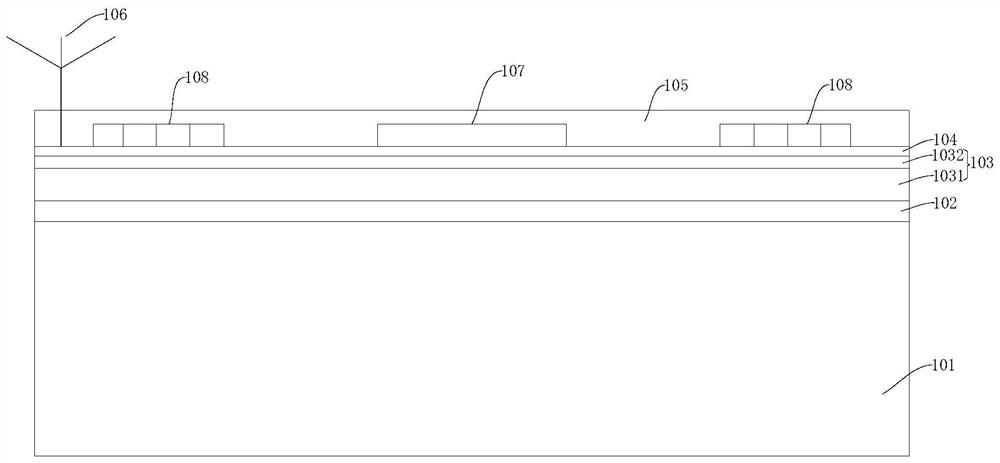

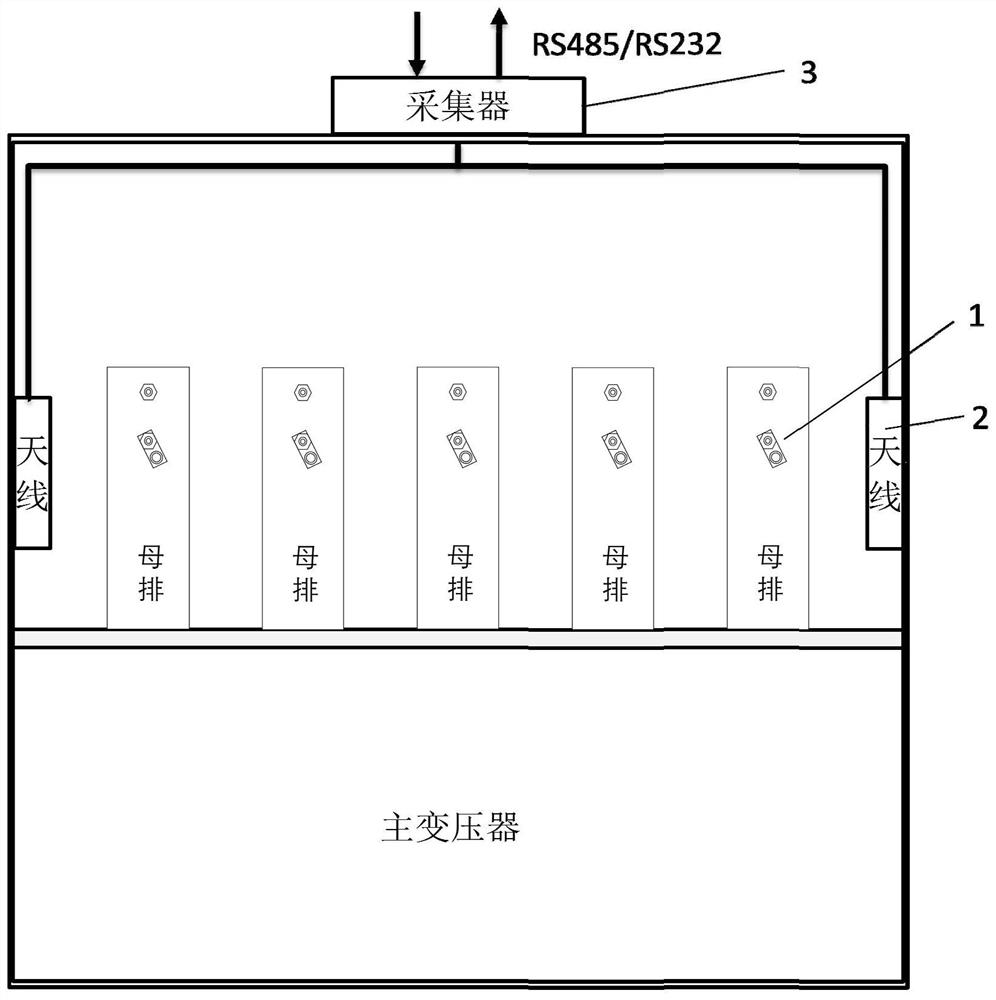

[0036] Such as figure 1 As shown, the wireless passive temperature sensing system for the electric locomotive auxiliary converter cabinet of this embodiment includes a surface acoustic wave temperature sensing unit 1, an antenna unit 2 and an acquisition unit 3; wherein the surface acoustic wave temperature sensing unit 1 is installed in the electric locomotive auxiliary At the temperature to be measured in the converter cabinet, the surface acoustic wave temperature sensing unit 1 is connected to the acquisition unit 3 through the antenna unit 2; the surface acoustic wave temperature sensing unit 1 includes a substrate 101, a piezoelectric substrate 103, an antenna module 106, an interdigital Transducer 107 and reflection grid 108; Piezoelectric substrate 103 comprises acoustic wave conduction substrate 1031 and the piezoelectric film 1032 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com