Forming device for linear motor stator processing and production

A technology of linear motor and forming device, used in positioning device, feeding device, storage device, etc., can solve the problems of stator blanking, affecting stamping, inconvenient for dust cleaning, etc., to achieve stable up and down movement, convenient clamping and stamping molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

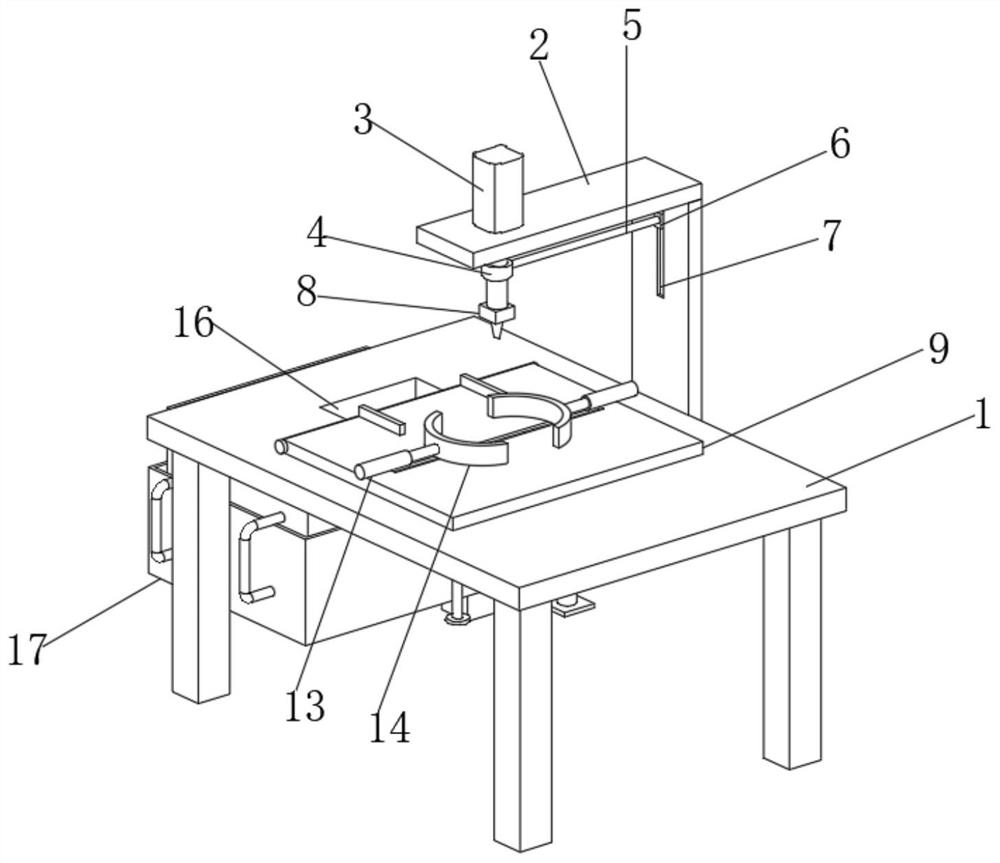

[0031] see Figure 1-3 , the present invention provides a technical solution: a linear motor stator processing and production forming device, including an operating frame 1, the top outer wall of the operating frame 1 is fixedly connected with a mounting frame 2, and the top outer wall of the mounting frame 2 is fixedly connected with a cylinder 3, The outer wall of the cylinder 3 is sleeved with a sleeve block 4, the outer wall of one side of the sleeve block 4 is fixedly connected with a connecting rod 5, the end of the connecting rod 5 away from the sleeve block 4 is fixedly connected with a first slider 6, and the outer wall of one side of the mounting frame 2 There is a first chute 7, the outer wall of the first slider 6 is slidingly connected with the inner wall of the first chute 7, one end of the cylinder 3 is fixedly connected with a stamping device 8, and the top outer wall of the operation frame 1 is movably connected with a processing console 9 The outer wall of th...

Embodiment 2

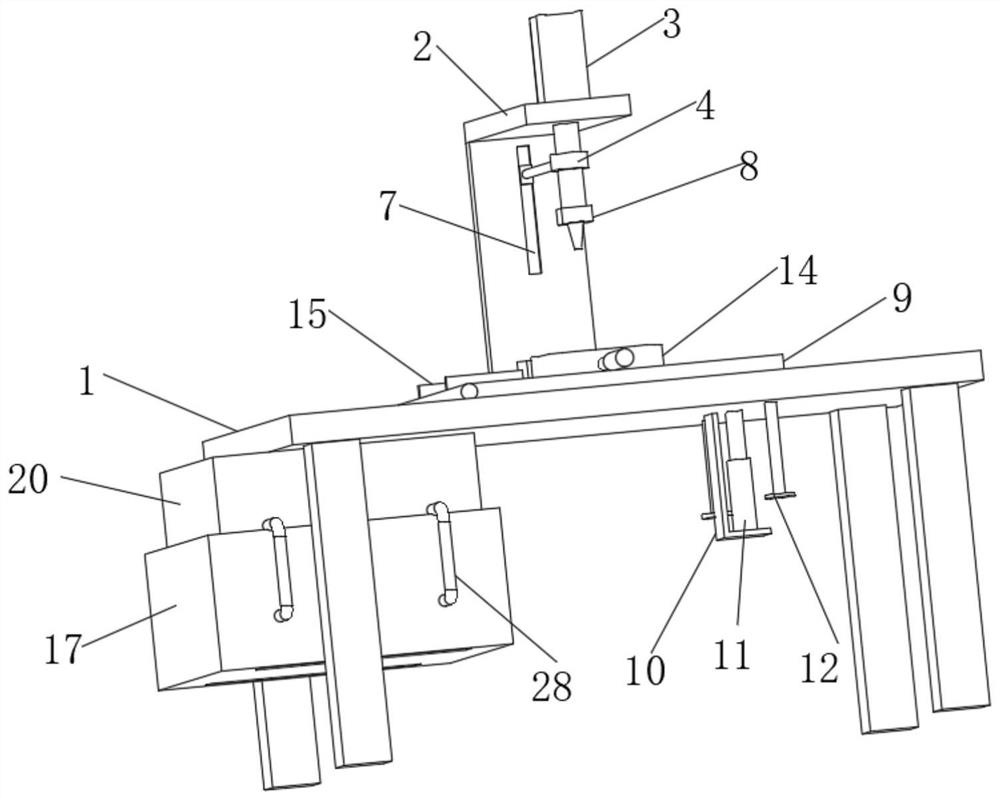

[0034] see Figure 4-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the inner wall of the operating frame 1 is provided with a feeding opening 16, and the top outer wall of the processing operation table 9 close to the feeding opening 16 is fixedly connected with a limit block 15, The outer wall of the bottom of the operating frame 1 is fixedly connected with a support column, and a waste box 17 is arranged between the outer walls of the support column. Block 19, the inner wall of the waste box 17 is provided with a receiving box 20, the outer walls of both sides of the receiving box 20 are fixedly connected with the outer wall of the second slide block 19 away from the second chute 18, and the inner wall of the receiving box 20 is provided with a material box 21 One side inner wall of the material box 21 is movably connected with an inclined plate 22, and the inclined plate 22 is arranged in an array with the vertical direction ...

Embodiment 3

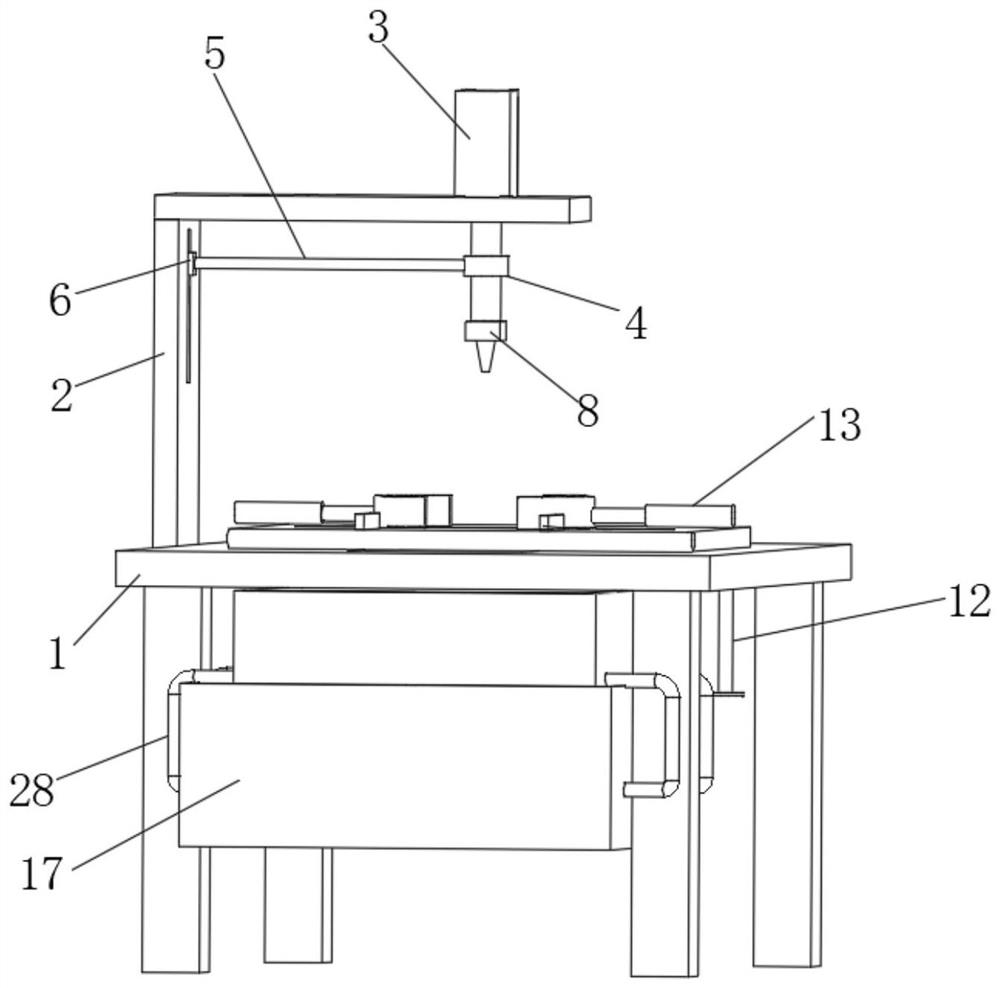

[0037] see Figure 8-9 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom of the inner wall of the waste box 17 is fixedly connected with an air bag 25, and the inner wall of the air bag 25 is fixedly connected with a rebound sponge 26, and the rebound sponge 26 A second spring 27 is fixedly connected between the outer walls of the airbag 25, and a delivery tube 28 is fixedly connected to the inner wall of the airbag 25. The end of the delivery tube 28 away from the airbag 25 is interspersed and arranged inside the receiving box 20 and the material box 21, and the delivery tube 28 is far away from the airbag 25. One end of the nozzle is fixedly connected with a nozzle 29, and the outer wall of the bottom of the receiving box 20 and the material box 21 is provided with a dust outlet 30.

[0038] In this embodiment, the dust generated by stamping falls into the material box 21 together with the inclination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com