VOCs waste gas treatment equipment

A waste gas treatment equipment, waste gas technology, applied in gas treatment, lighting and heating equipment, air quality improvement and other directions, can solve the problems of large VOCs waste gas, affecting VOCs waste gas treatment efficiency, long recovery time, etc., to achieve efficient and balanced recovery Activity, reduce activity recovery time, and ensure the effect of absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

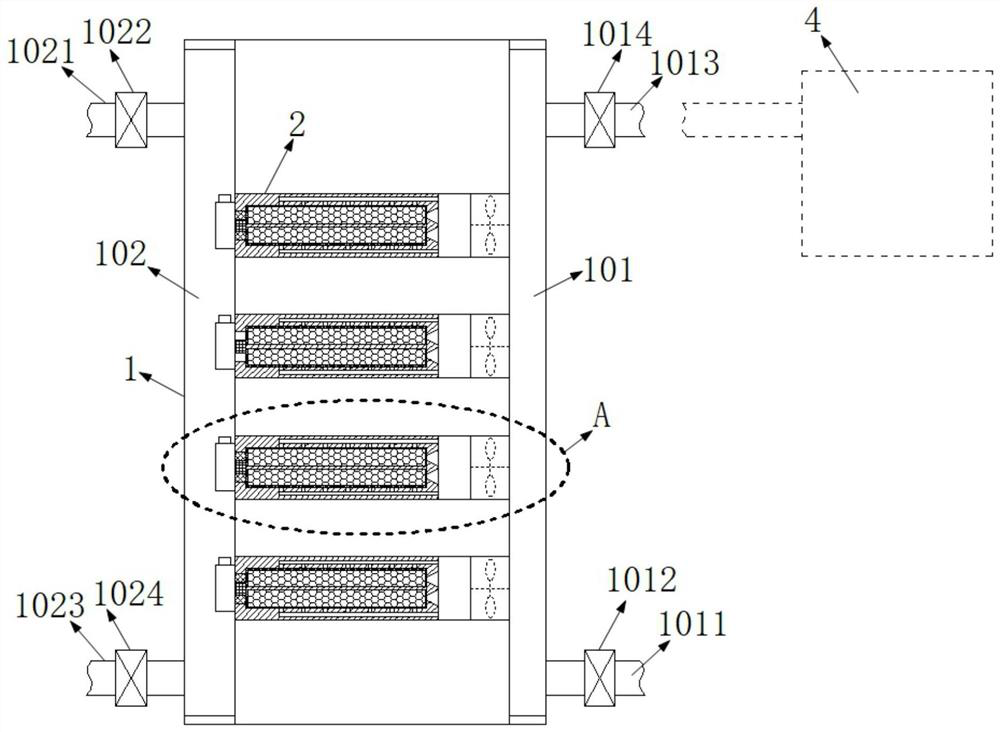

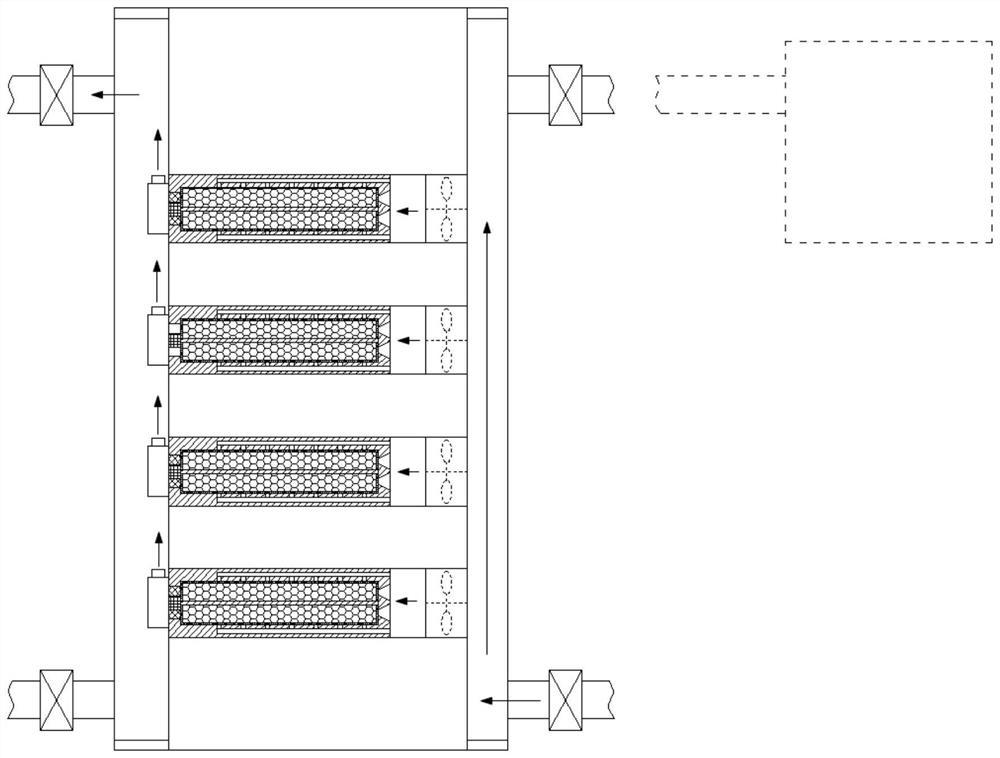

[0052] The waste gas absorbing device 1 includes a waste gas inlet channel 101 and a waste gas outlet channel 102 . One side of the waste gas absorbing device 1 is communicated with a first intake pipe 1011 .

[0053] The first air intake pipe 1011 is provided with an intake electromagnetic valve 1012 , and the other side of the waste gas absorption device 1 is connected with a first air outlet pipe 1021 , and the first air outlet pipe 1021 is connected with the waste gas outlet channel 102 .

[0054] The first intake pipe 1011 is provided with an intake solenoid valve 1012 , and the backflow outlet pipe 1013 is provided with a backflow solenoid valve 1014 .

[0055] The first air outlet pipe 1021 is equipped with an air outlet solenoid valve 1022 , and the backflow inlet pipe 1013 is equipped with a ventilation solenoid valve 1024 .

[0056] One side of the waste gas absorption device 1 is provided with a backflow inlet pipe 1013 connected with the exhaust gas outlet channel ...

Embodiment 2

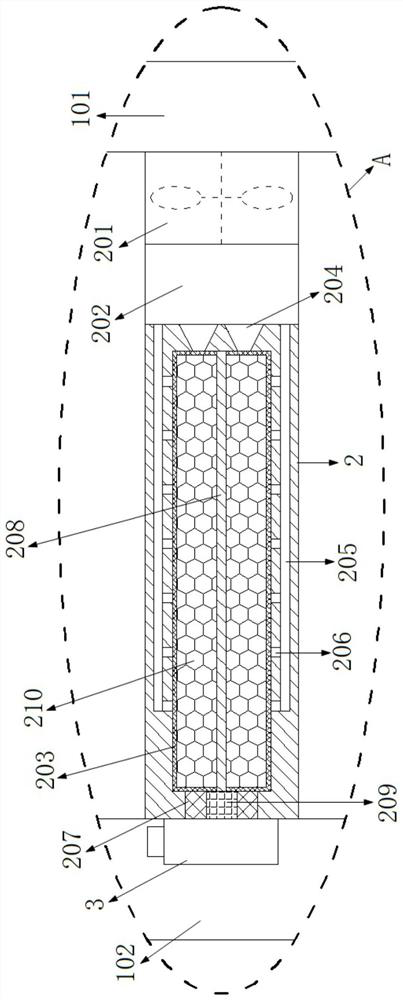

[0058] Exhaust gas absorbing device 1 is provided with a number of exhaust gas absorbing horizontal pipes 2 located between the exhaust gas inlet channel and the exhaust gas outlet channel 102. The exhaust gas absorbing horizontal tube 2 includes a negative pressure fan 201, and the negative pressure fan 201 communicates with the exhaust gas inlet channel 101. The exhaust gas absorption horizontal pipe 2 includes a negative pressure inner chamber 202, which is adjacent to the negative pressure fan 201, and the exhaust gas absorption horizontal pipe 2 includes an activated carbon mesh cover 203, and the activated carbon mesh cover 203 is filled with internal activated carbon 210.

[0059] In the waste gas absorption horizontal pipe 2, a shell structure surrounding the periphery of the activated carbon mesh cover 203 is arranged. A first main port 204 is opened on one side of the shell structure, and the first main port 204 communicates with the activated carbon mesh cover 203. T...

Embodiment 3

[0064] The VOCs waste gas treatment equipment includes a control platform, which is equipped with a main processing controller. The main processing controller communicates with the peripheral ventilation solenoid valve 3, intake solenoid valve 1012, return flow solenoid valve 1014, outlet solenoid valve 1022, The ventilation solenoid valve 1024, the heating rod 208, the negative pressure fan 201 and the organic gas combustion furnace 2 are connected, and the main processing controller is connected with the temperature sensing module 209 through a data line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com