Moisturizing cream capable of relieving arthralgia and improving joint vitality as well as preparation method and use method of moisturizing cream

A technology for joint pain and moisturizing cream, which is applied in the field of moisturizing cream and its preparation, can solve the problems of poor use effect and achieve the effects of relieving joint fatigue, improving utilization rate, and improving use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A moisturizer that can relieve joint pain and improve joint vitality, each component and its corresponding quality are as shown in Table 2, and are prepared through the following steps:

[0048] S1, add deionized water, 1,3-propanediol, glycerin, and xanthan gum into the aqueous phase stirring tank, raise the temperature to 80°C, and stir at a speed of 1000r / min for 15min, keep it warm for 30min, then add glucosamine, beet Alkali, stirred at 1000r / min for 15min to obtain the aqueous phase;

[0049] S2, caprylic / capric triglyceride, cetearyl alcohol, cetearyl glucoside, squalane, jojoba seed oil, grape seed oil, glyceryl stearate, phytozil / octyl Lauryl alcohol lauroyl glutamate and tocopheryl acetate were added to the oil phase stirring tank, the temperature was raised to 75°C, and stirred at a speed of 1000r / min for 20 minutes, and kept for 30 minutes to obtain the oil phase;

[0050] S3, pump the water phase and the oil phase into the emulsification tank, and emulsify...

Embodiment 2-12

[0055] A moisturizing cream capable of relieving joint pain and improving joint vitality, the difference from Example 1 is that each component and its corresponding quality are shown in Table 2 and Table 3.

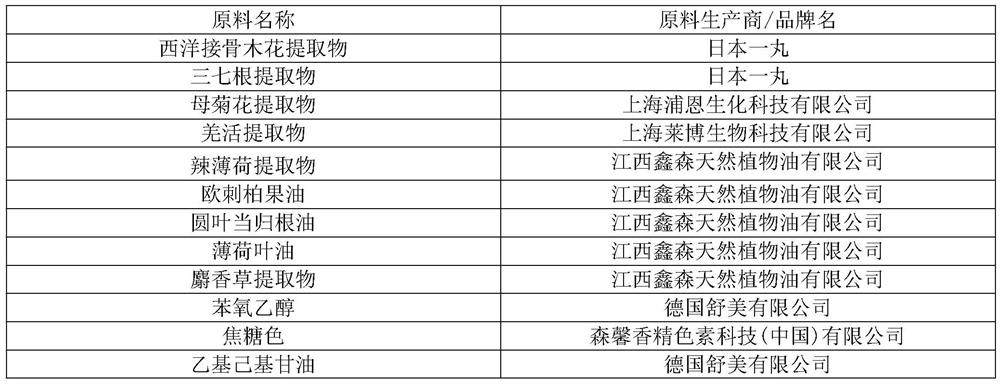

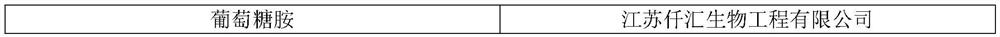

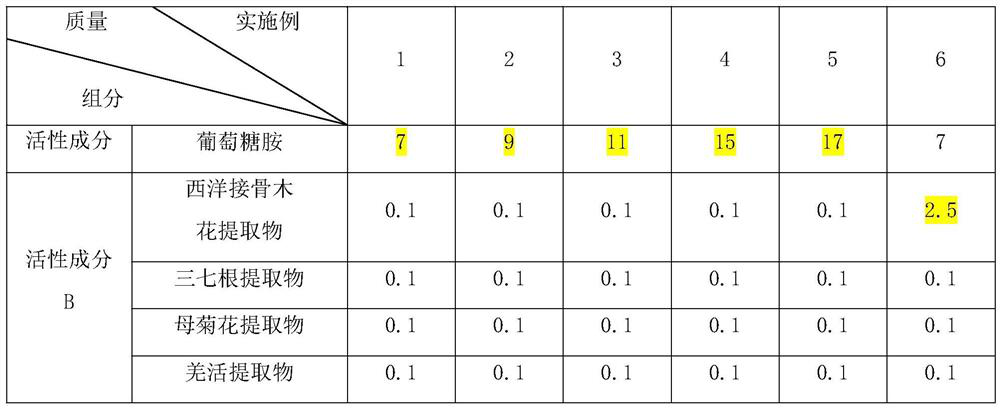

[0056] Each component and its quality (kg) in table 2 embodiment 1-6

[0057]

[0058]

[0059] Each component and its quality (kg) in table 3 embodiment 7-12

[0060]

[0061]

Embodiment 13

[0063] S1, add deionized water, 1,3-propanediol, glycerin, and xanthan gum into the water phase stirred tank, raise the temperature to 85°C, stir and dissolve at a speed of 1800r / min for 15min, keep it warm for 30min, then add glucosamine, Betaine, stirred at 1800r / min for 15min to obtain an aqueous phase;

[0064] S2, caprylic / capric triglyceride, cetearyl alcohol, cetearyl glucoside, squalane, jojoba seed oil, grape seed oil, glyceryl stearate, phytozil / octyl Add lauryl lauroyl glutamate and tocopheryl acetate into the oil phase stirring tank, heat up to 80°C, stir at a speed of 1800r / min for 20min, and keep warm for 30min to obtain the oil phase;

[0065] S3, pump the water phase and the oil phase into the emulsification tank, and homogeneously emulsify at a speed of 3000r / min for 3min to obtain a mixture 1;

[0066] S4, stirring menthol, ethanol and menthol lactate at a speed of 1800r / min for 15min to obtain mixture 2;

[0067] S5, lower the temperature of mixture 1 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com