A switch matrix multi-beam component and a switch matrix multi-beam extended component

A switch matrix and multi-beam technology, applied in the field of radio frequency, can solve the problems of low integration of microwave switch matrix, limit the application range of switch matrix, complex system redundancy, etc., reduce the number of external interfaces, reduce system complexity, The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

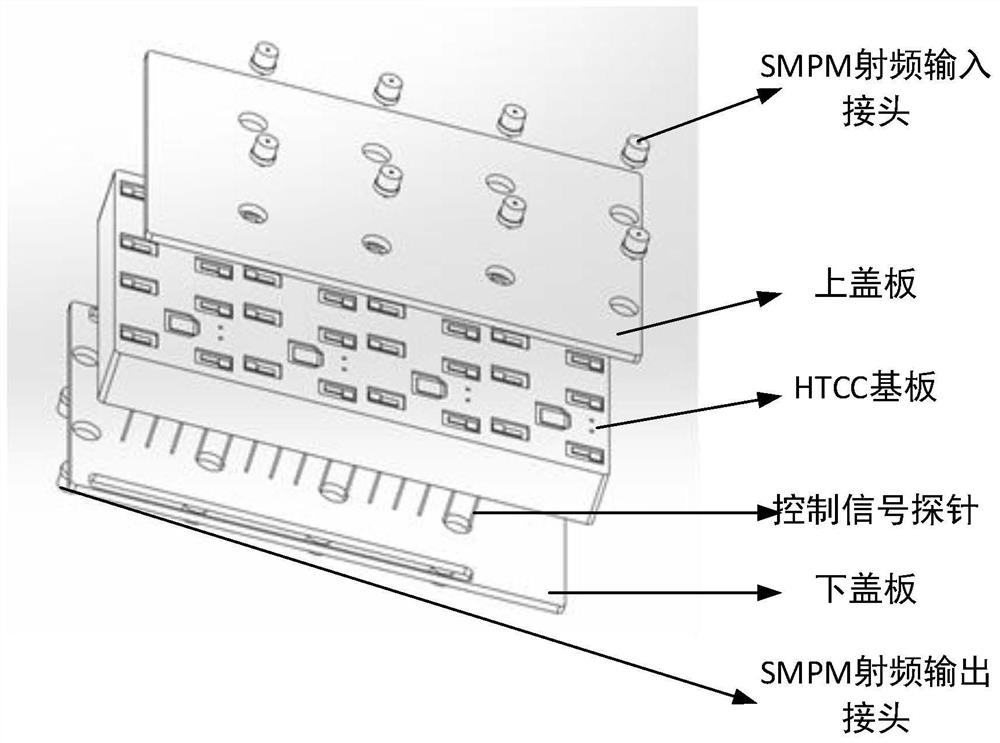

[0030] Such as figure 1 As shown, this embodiment provides an 8×8 tile-type switch matrix multi-beam component (tile type means that chips are divided into functions and stacked horizontally on the substrate and assembled vertically, that is, one functional area per layer), including the above The top cover with 8 sub-Miniature Push-on Micro (SMPM) RF input connectors, the HTCC (High- temperature co-fired ceramics, high temperature co-fired ceramics) substrate, lower cover with 8 ultra-miniature push-in connector RF output connectors;

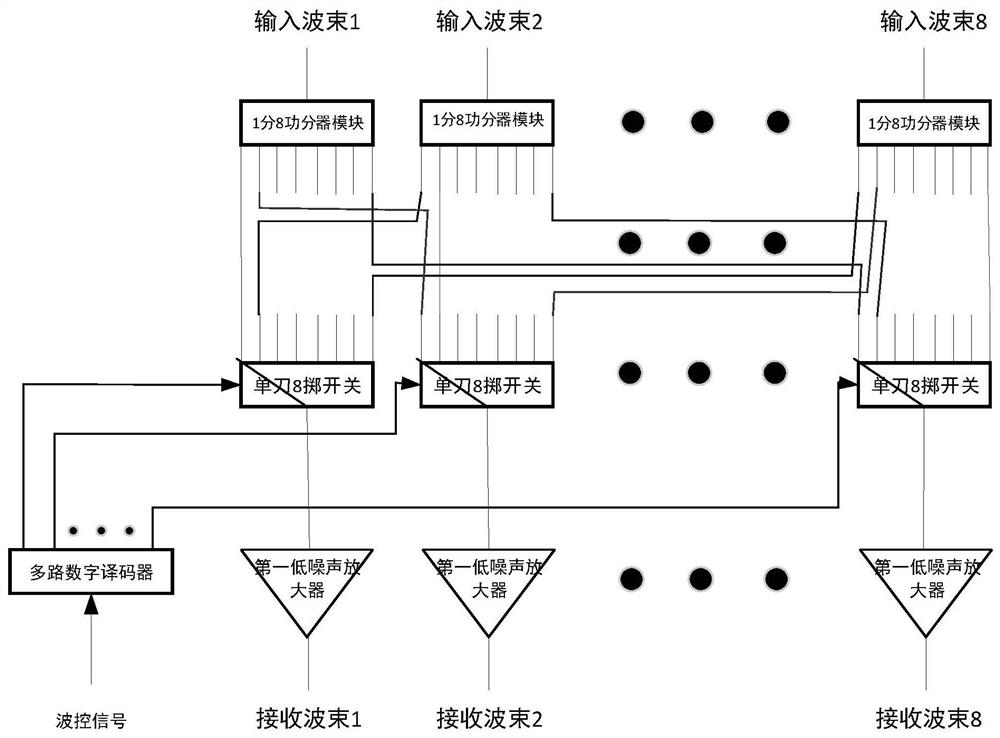

[0031] The HTCC substrate containing the tile-type switch matrix circuit includes 8 one-to-8 power divider modules on the top layer, 8 single-pole 8-throw switches on the bottom layer, 8 low-noise amplifiers, a multi-channel digital decoder and Two rows of control signal probes, and a multilayer structure radio frequency interconnection layer between the top layer and the bottom layer, the multilayer structure radio frequency interconnection l...

Embodiment 2

[0041] This embodiment provides an HTCC-based 2×4 tile-type switch matrix multi-beam component, which includes an upper cover plate with 2 SMPM RF input connectors arranged in sequence from top to bottom, including a 2×4 tile-type The HTCC substrate of the switch matrix circuit, the lower cover with 4 SMPM RF output connectors; the HTCC substrate containing the 2×4 tile switch matrix circuit is layered and laid out using the HTCC packaging process, including the 2 on the top layer A one-to-four power divider module, four single-pole double-throw switches located on the bottom layer, four first low-noise amplifiers, a multi-channel digital decoder and two rows of control signal probes, and the top and bottom layers between the A radio frequency interconnection layer with a multilayer structure; the radio frequency interconnection layer with a multilayer structure implements beam signal transmission through multilayer radio frequency wiring.

[0042] The working flow chart of th...

Embodiment 3

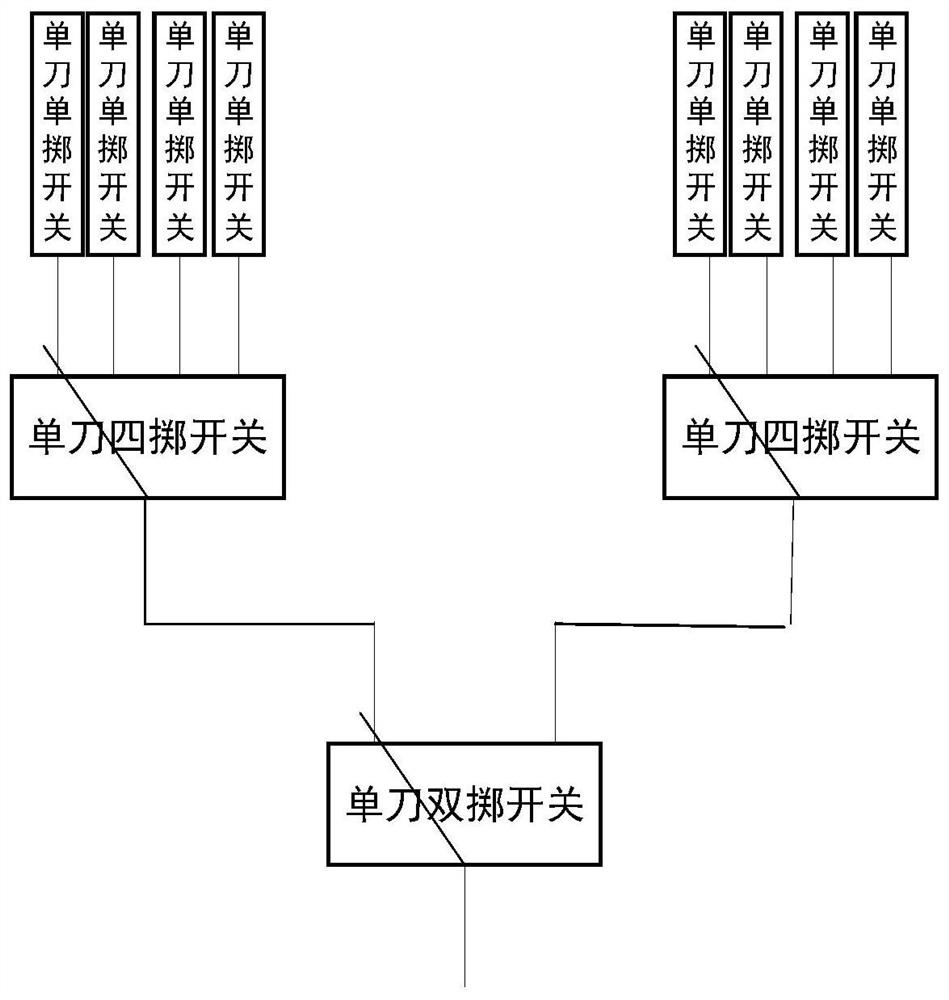

[0046] This embodiment provides an HTCC-based 16×16 tile-type switch matrix multi-beam expansion component, including an upper cover with 16 SMPM RF input connectors arranged sequentially from top to bottom, including 16 one-point HTCC substrate of two power dividers, copper-molybdenum-copper upper substrate with fur buttons, HTCC substrate array with tile switch matrix circuit, copper-molybdenum-copper lower substrate with fur buttons, 16 SPDT switches HTCC substrate, a lower cover plate with 16 SMPM RF output connectors, the HTCC substrate containing single-pole double-throw switches also contains the first multi-channel digital decoder and two rows of control signal probes; the tile-type The total number of input beams of the HTCC substrate array of the switch matrix circuit is 32;

[0047] The HTCC substrate array containing the tile-type switch matrix circuit is composed of 4 HTCC substrates containing the 8×8 tile-type switch matrix circuit obtained in Embodiment 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com