A kind of azeotrope separation coupling process and device

A separation device and azeotrope technology, which can be used in measurement devices, material separation, and analysis of materials, etc., and can solve problems such as minimal separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

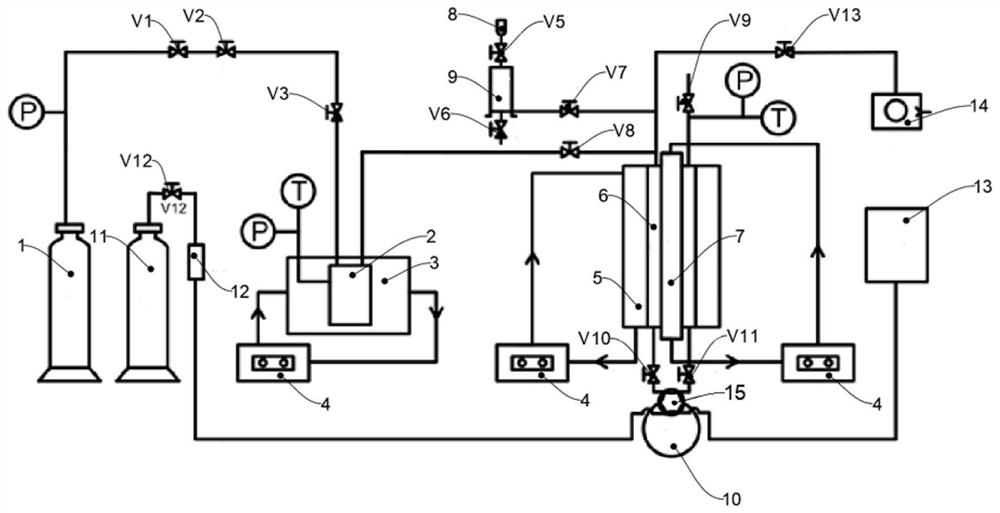

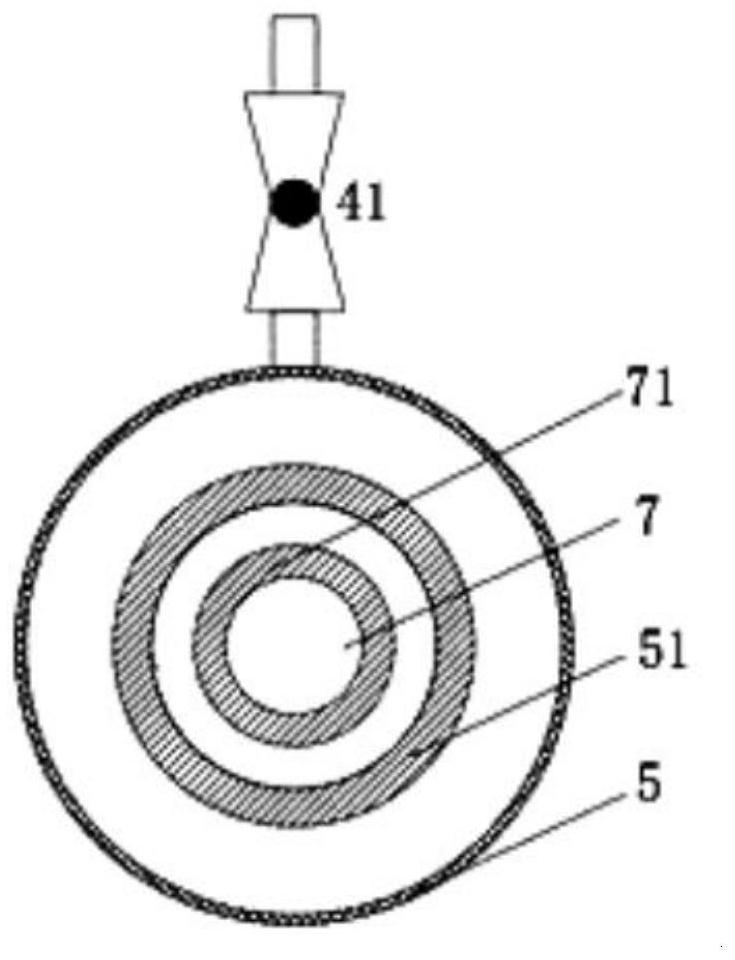

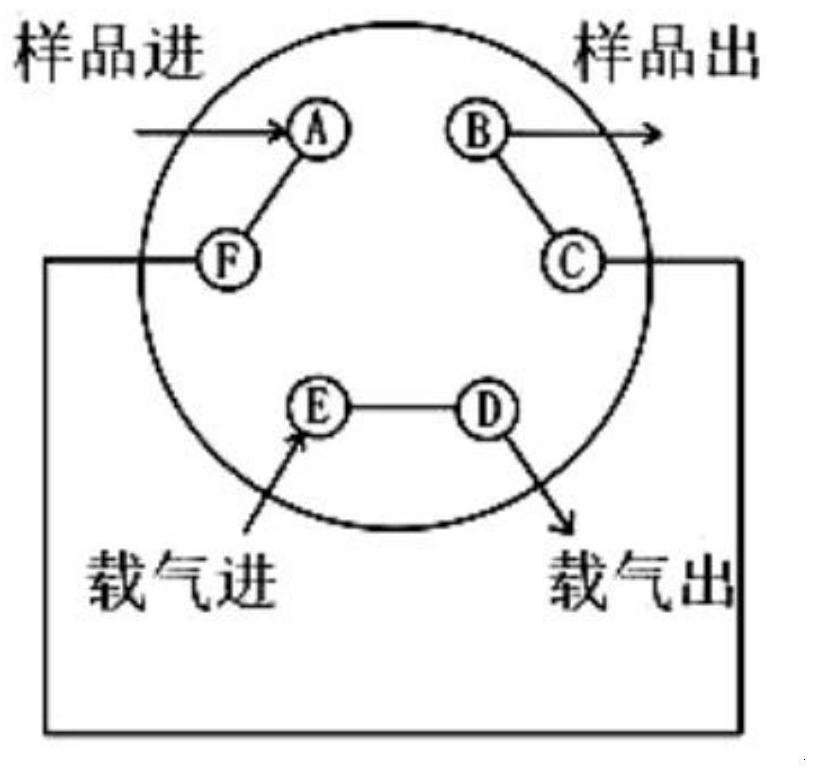

[0040] Such as figure 1 As shown, this embodiment provides an azeotrope separation coupling device, including a supercritical fluid preparation part, an azeotrope separation part, and a sampling part; wherein, the supercritical fluid preparation part is used to prepare supercritical CO 2 Fluid will prepare supercritical CO 2 The fluid is passed into the azeotropic mixture separation part; the azeotropic mixture separation part can use the thermal diffusion effect to separate the azeotropic mixture and dissolve one of the separated phases in supercritical CO 2 In the fluid; the sampling part is used to sample the separated components.

[0041] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com