Fabricated building structure convenient for butt joint and grouting

A building structure and assembly technology, which is applied to building components, building structures, buildings, etc., can solve the problems of affecting the construction progress, inconvenient assembly process, and difficult to accurately connect the plug rods, etc., so as to increase stability and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

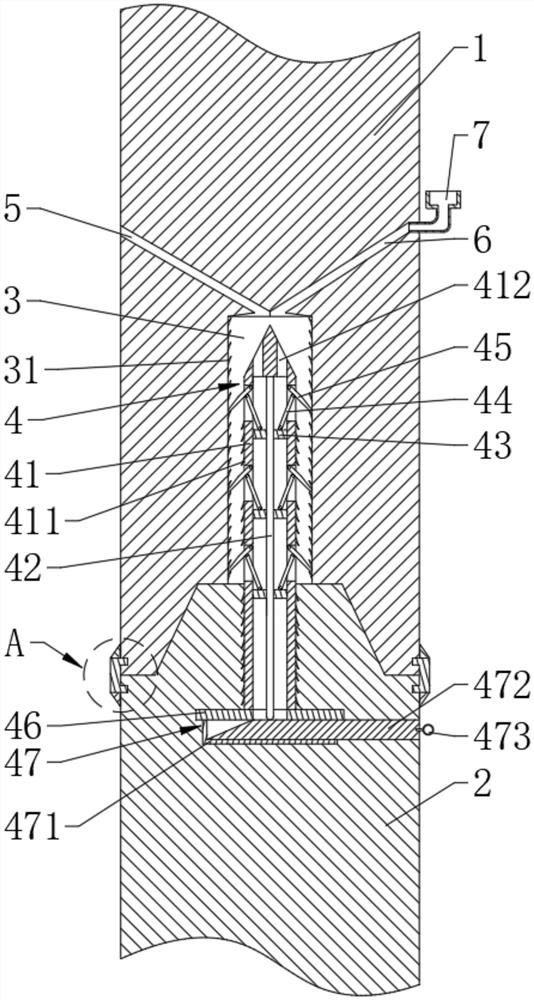

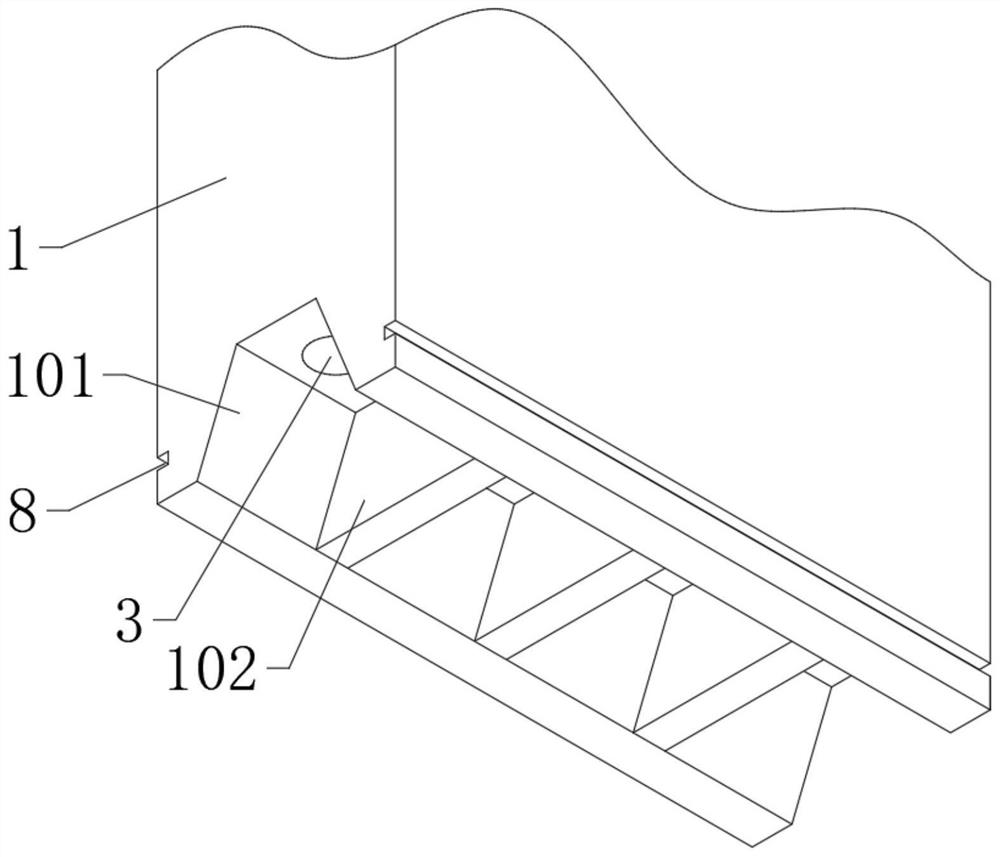

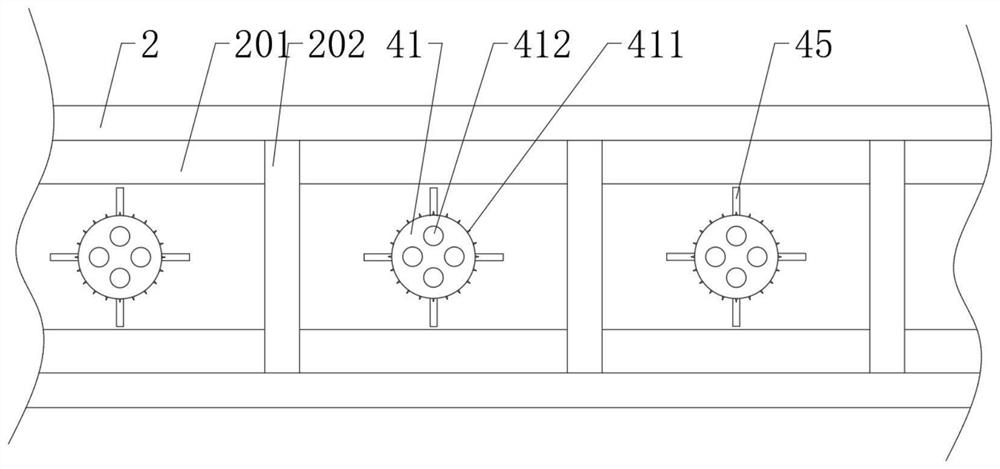

[0033] Such as figure 1 and figure 2 As shown, it is a prefabricated building structure disclosed by the present invention that is convenient for docking and grouting, including an upper wall 1 and a lower wall 2, and a groove 101 is opened at the bottom of the upper wall 1, and a groove 101 is fixedly connected with a Several evenly distributed partitions 102, the cavity 3 is arranged between the adjacent partitions 102 in the groove 101, when the upper wall 1 is made, the cavity 3 can be placed in the mold of the upper wall 1 Cavities 3 of the same size are made into moulds, so that the cavity 3 can be made on the upper body of wall 1; as image 3 As shown, the top of the lower wall 2 is provided with a boss 201, and the boss 201 is spliced in the groove 101. The cross-sections of the boss 201 and the groove 101 are both trapezoidal, and the cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com