Self-adjusting raw coke oven gas device for single-carbonization-chamber coke oven

A self-regulating, waste gas technology, applied in coke ovens, chemical instruments and methods, using liquid separating agents, etc., can solve problems such as affecting the production process, tie rod breakage, low gas recovery rate, etc., to increase service life, prevent nozzles blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

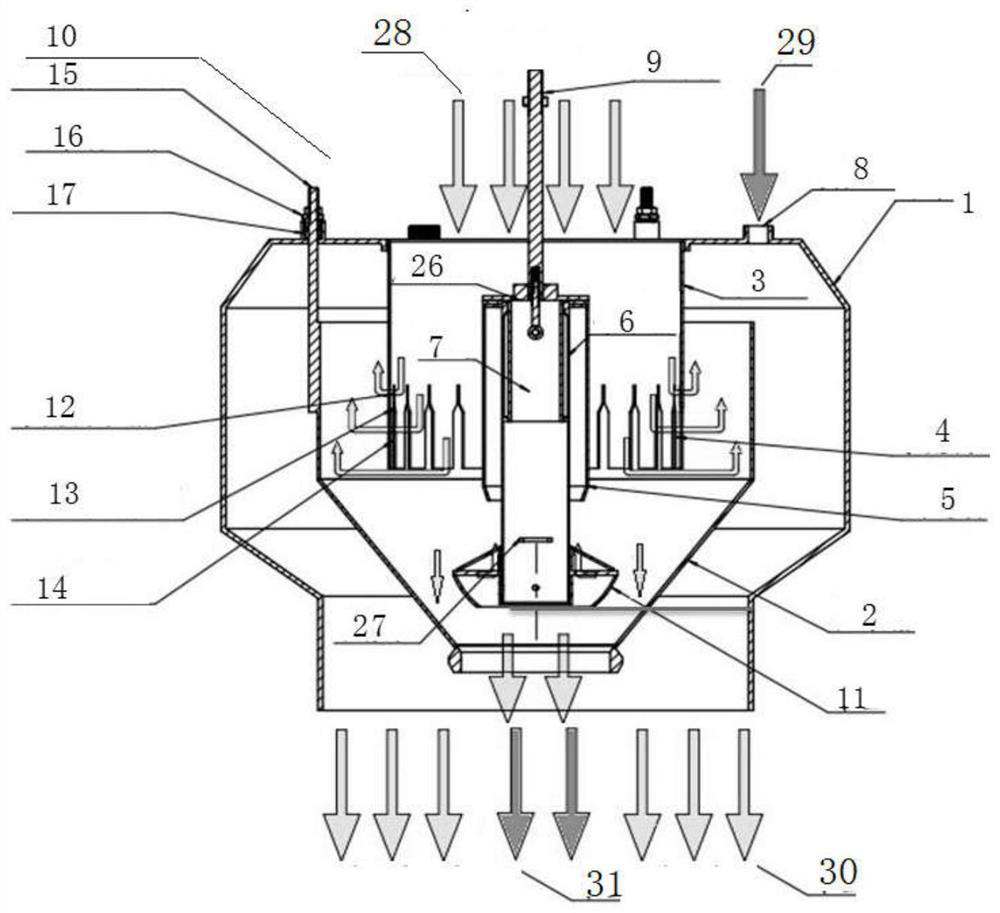

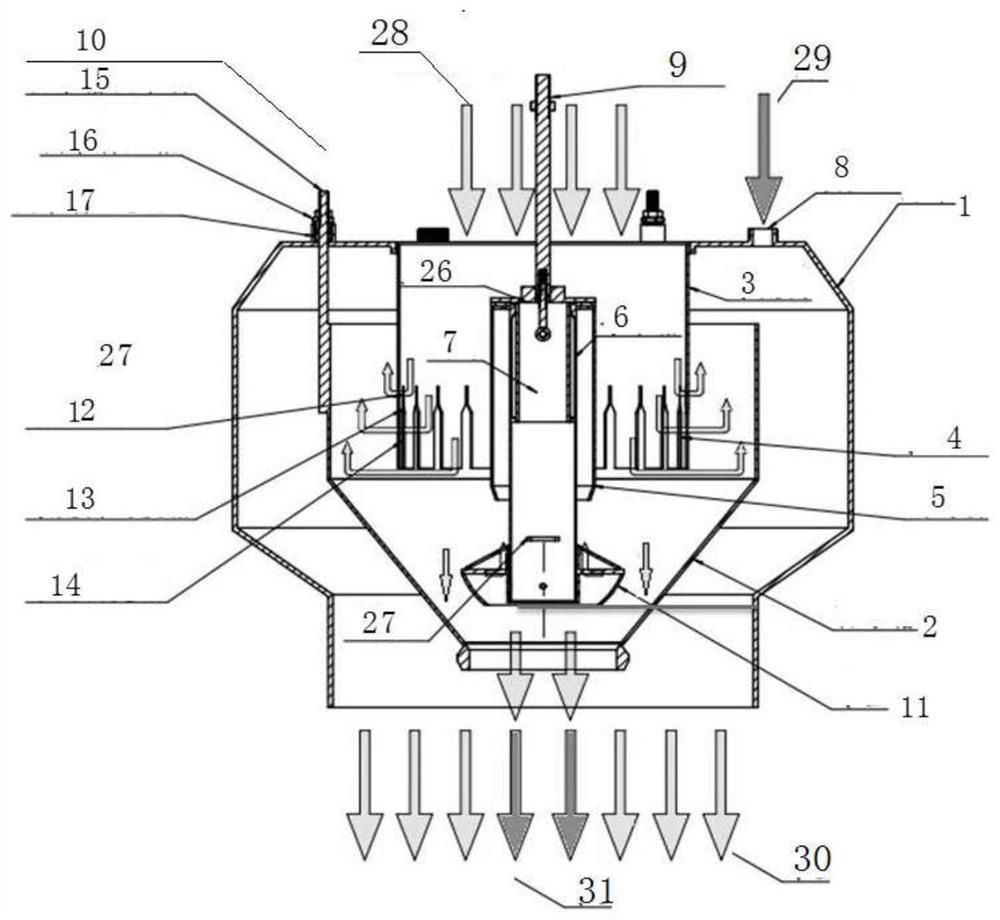

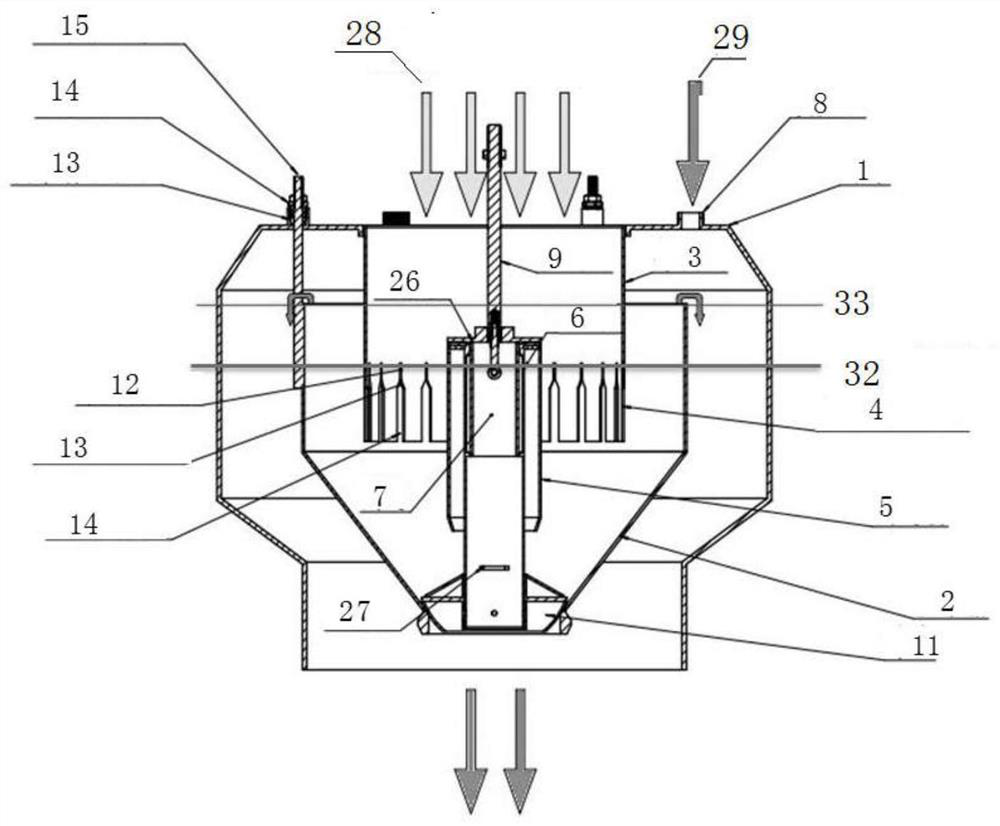

[0037] A self-regulating raw gas device for a coke oven with a single carbonization chamber, comprising a rising pipe, a bridge pipe, a gas collecting pipe, an integrated water seal valve, a first nozzle, and a second nozzle; one end of the bridge pipe is connected to the rising pipe, and the other end is Along the vertical direction, it is connected with the upper end of the integrated water seal valve;

[0038] The bottom of the integrated water seal valve is connected to the top of the air collecting pipe, one end of the piston rod inside the integrated water seal valve is fixedly installed on the top, and the other end extends to the inside of the bridge pipe, and the integrated water seal valve includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com