A kind of high elastic composite polymer material and its preparation process

A composite polymer, high-elasticity technology, applied in branch equipment, telephone structure, electrical components, etc., can solve problems such as difficulty in exerting elastic properties, unsolved trade-off relationship between mechanical properties of rubber elastomer colloidal particles, etc., to maintain structural stability. performance, increase toughness and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

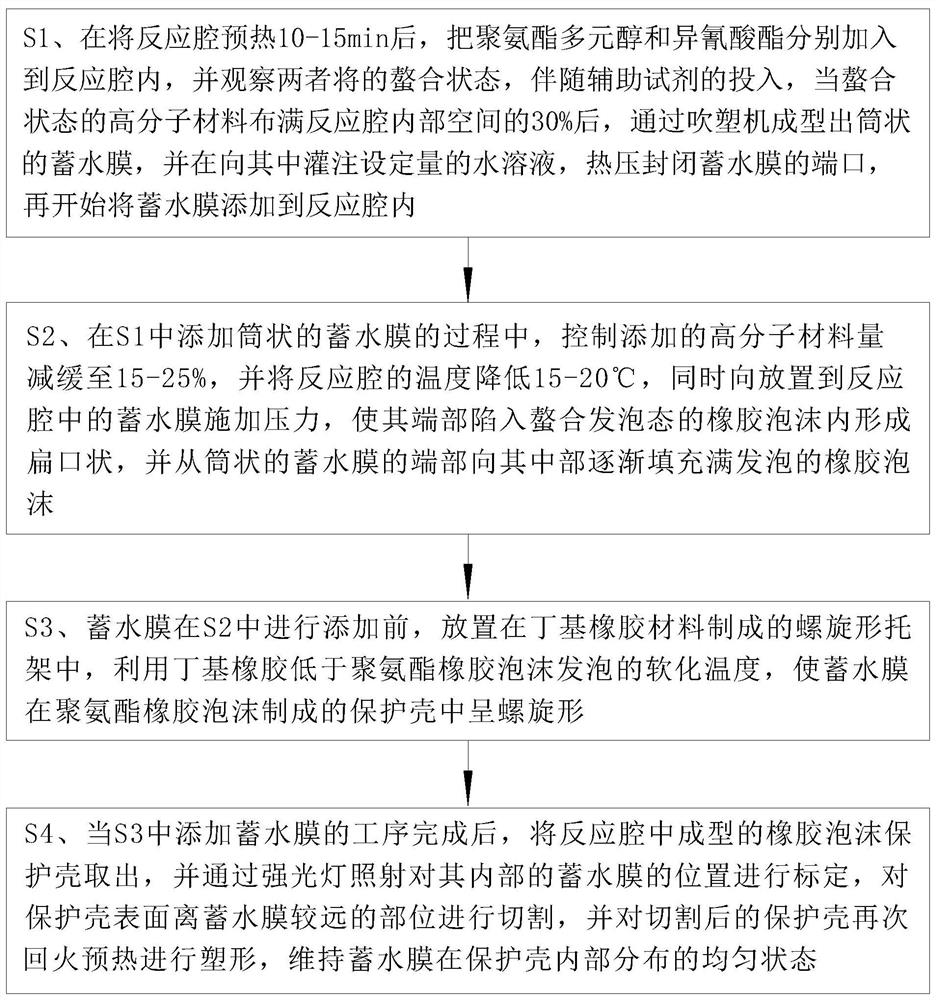

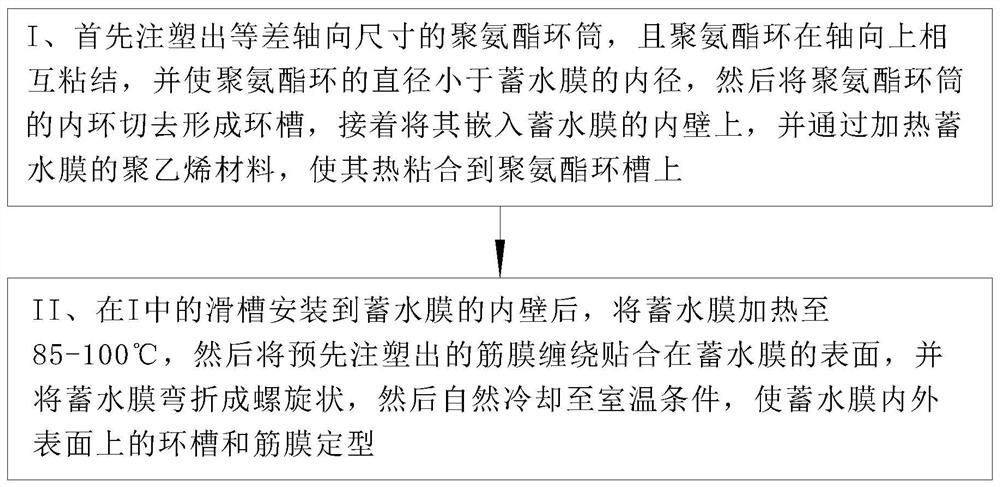

Method used

Image

Examples

Embodiment approach

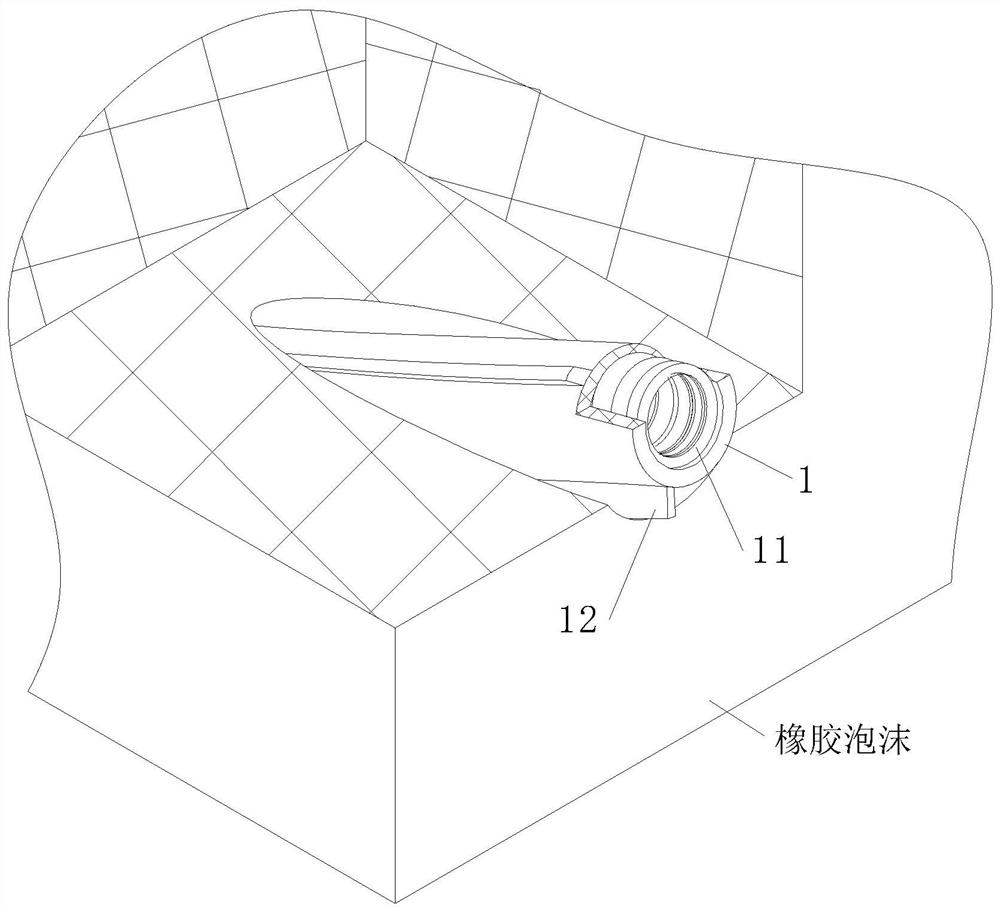

[0032] As an embodiment of the present invention, the water storage membrane 1 is further provided with a concave annular groove 11 on its end, and the annular groove 11 is distributed on the inner wall of the water storage membrane 1 in a fin shape. The axial direction is parallel to the length direction of the water storage membrane 1; the size of the annular groove 11 gradually increases from the end of the cylindrical water storage membrane 1 to the middle; When the water film 1 is subjected to an impact, the deformation generated by the fin-shaped ring groove 11 will collapse and deform, thereby achieving the effect of absorbing the impact energy, reducing the force of the damage to the protective shell structure, and the aqueous solution filled in the water storage film 1. In the process of falling, it converges to the bottom of the water storage membrane 1 in the direction of gravity, so that the structural strength of the ring groove 11 at the bottom of the water storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com