Method for comprehensively treating electroplating comprehensive wastewater

A comprehensive and comprehensive electroplating treatment technology, which is applied in special compound water treatment, filtration treatment, precipitation treatment, etc., can solve the problems of difficult treatment, large variation in electroplating wastewater quality, and complex components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

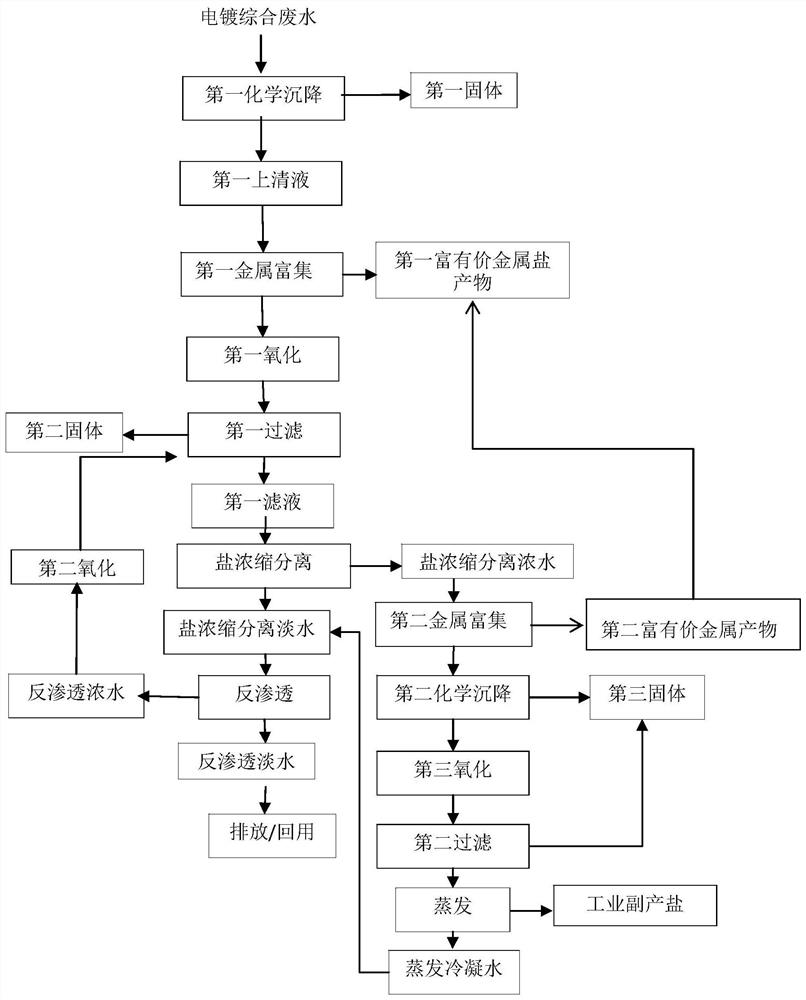

[0082] Collect comprehensive electroplating wastewater, sample and analyze electroplating wastewater, its composition is: suspended matter 200mg / L, COD1500mg / L, ammonia nitrogen 150mg / L, total nitrogen 1000mg / L, total phosphorus 1200mg / L, total copper 800mg / L, total chromium 1200mg / L, total nickel 900mg / L, total zinc 1000mg / L, total iron 200mg / L, total aluminum 800mg / L. The treatment process of comprehensive electroplating wastewater is as follows: figure 1 As shown, the specific steps are as follows:

[0083] 1) Adjust the pH value of the comprehensive electroplating wastewater to 6.5, and stir for 60 minutes. Adding mass concentration is 0.1% PAM, the adding amount of said PAM is 6L / m 3 The comprehensive electroplating wastewater was added with PAM and then reacted for 30 minutes, followed by pressure filtration to obtain the first supernatant and the first solid.

[0084] The pollutant components and contents in the first supernatant are: suspended matter 5mg / L, COD 980m...

Embodiment 2

[0104] Collect comprehensive electroplating wastewater, sample and analyze electroplating wastewater, its composition is: suspended matter 50mg / L, COD3500mg / L, ammonia nitrogen 50mg / L, total nitrogen 100mg / L, total phosphorus 120mg / L, total copper 100mg / L, total chromium 200mg / L, total nickel 300mg / L, total zinc 150mg / L, total iron 1000mg / L, total aluminum 200mg / L, etc. The treatment process of comprehensive electroplating wastewater is as follows: figure 1 As shown, the specific steps are as follows:

[0105] 1) Adjust the pH value of the comprehensive electroplating wastewater to 5.5, and stir for 60 minutes to react. Adding mass concentration is 0.1% PAM, the adding amount of said PAM is 6L / m 3 The comprehensive electroplating wastewater was added with PAM and then reacted for 30 minutes, followed by pressure filtration to obtain the first supernatant and the first solid.

[0106] The content of each pollutant component in the first supernatant is: suspended matter 5mg / L...

Embodiment 3

[0123] Collect comprehensive electroplating wastewater, sample and analyze electroplating wastewater, its composition is: suspended matter 20mg / L, COD 500mg / L, ammonia nitrogen 50mg / L, total nitrogen 100mg / L, total phosphorus 120mg / L, total copper 100mg / L, total Chromium 200mg / L, total nickel 300mg / L, total zinc 150mg / L, total iron 300mg / L, total aluminum 400mg / L, etc. The treatment process of comprehensive electroplating wastewater is as follows: figure 1 As shown, the specific steps are as follows:

[0124] 1) Adjust the pH value of the comprehensive electroplating wastewater to 5.5, and stir for 60 minutes to react. Adding mass concentration is 0.1% PAM, the adding amount of said PAM is 6L / m 3 The comprehensive electroplating wastewater was added with PAM and then reacted for 30 minutes, followed by pressure filtration to obtain the first supernatant and the first solid. The content of each pollutant component in the first supernatant is: suspended matter 5mg / L, COD 400m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com