Automatic capacitor production auxiliary equipment

A production auxiliary and capacitor technology, which is applied in the direction of capacitors, capacitor manufacturing, laminated capacitors, etc., and can solve the problems of stacking, irregularity, and infirmity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

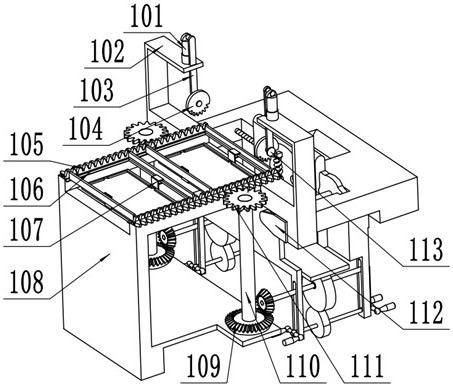

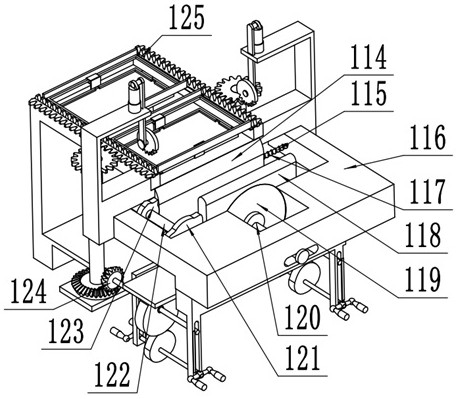

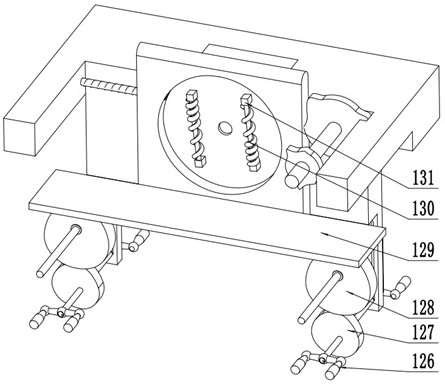

[0016] Example: figure 1 , figure 2 , image 3 An automated capacitor produced auxiliary equipment, including a sliding rack 105, mounting frame 106, a base 108, a back plate 114, a slider 118, sliding the rack 105, sliding on the base 108, mounting frame 106 sliding mounting in the base 108 On the upper, the slide groove 125 is provided on the sliding rack 105, and the mounting frame 106 is provided with a rotating shaft in the sliding rack 105 sliding direction, and the shaft rotation is mounted on the slide groove 125, and the mounting frame 106 is fixedly mounted with a cardboard 107. The card plate 107 is located on the two edges opposite to the mounting frame 106, and the ceramic diaphragm is mounted on the card plate 107, and the bracket 102 is fixed to the base 108, and the retracting rod 101 is fixedly mounted on the bracket 102, and one end of the mounting plate 103 is fixedly mounted At the active end of the telescoping rod 101, the incomplete gear 104 is rotated to be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com