Metal composite component based on fiber reinforcement and manufacturing method thereof

A metal composite and fiber-reinforced technology, applied in instrumentation, geometric CAD, design optimization/simulation, etc., can solve problems such as fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

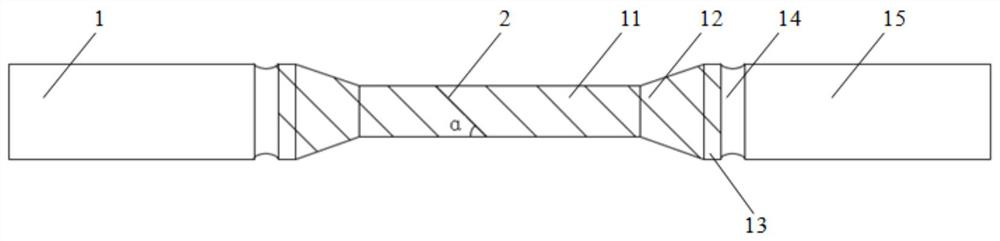

[0075] A number of grooves at 45° to the horizontal direction are opened on the metal substrate, and the grooves are filled with a large-strain fiber material (LRS-FRP) with an elastic modulus of 8GPa and a limit strain of 10%, to obtain a fiber-reinforced metal Composite member1.

Embodiment 2

[0077] A number of grooves at 30° to the horizontal direction are opened on the metal substrate, and the grooves are filled with glass fiber material (GFRP) with an elastic modulus of 55GPa and a limit strain of 3%, to obtain a fiber-reinforced metal composite component 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com