Cast-in-place pile concrete vibration device

A vibrating device and concrete technology, which is applied in construction, building structure, construction material processing, etc., can solve problems such as inability to effectively vibrate concrete, floating of steel cages, damage of pile drivers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

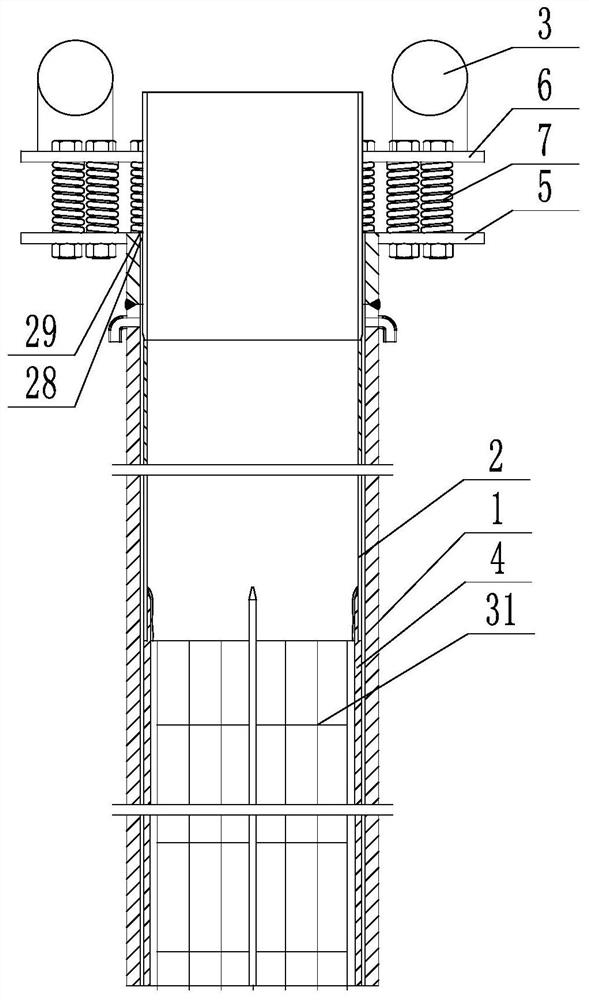

[0027] Such as figure 1 As shown, the present invention relates to a concrete vibrating device for cast-in-situ piles, comprising a base 5, an inner pipe 2, a vibrating device 3, and a steel brazing rod 4. The base 5 is provided with a lifting lug 30, which is used for connecting The steel wire rope is used to lift and fix the base 5. The base 5 can also be located on the ground or on the outer pipe during the construction of the immersed pipe pouring pile. The base 5 is provided with an inner pipe insertion port 29, and the inner pipe 2 Pass through the base 5 from the inner tube insertion port 29, a gap 28 is provided between the outer wall of the inner tube 2 and the inner tube insertion port 29, and a plurality of steel brazing rods 4 are arranged around the inner tube 2 below the tube wall , the steel brazing rod 4 is welded on the inner pipe 2, but it is not limited to welding, it can also be connected by other methods such as screw connection, and the steel brazing rod ...

specific Embodiment 2

[0029] Such as figure 2 As shown, on the basis of specific embodiment 1, when applied to cast-in-place piles such as immersed pipes, when there are cast-in-situ piles with steel casing wall (outer pipe), lifting lugs 30 may not be provided, and the base 5 is inside The outer pipe 1 extends downward from the pipe insertion opening 29. In this embodiment, the inner pipe insertion opening 29 is circular in shape corresponding to the pile hole, and the outer pipe 1 is inserted into the soil layer above the pile tip using a pile driver.

[0030] Further examples such as image 3 , Figure 4 , Figure 5 , Figure 6As shown, it also includes an air pressure sealing device 8, the air pressure sealing device 8 includes a valve body 9, a cover plate 10, a pressurization mechanism 11, a valve cavity 12 is formed in the valve body 9, and an air inlet is opened in the valve cavity 12 13. The valve chamber 12 is connected to the supercharging mechanism 11 through the air inlet 13. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com