An intelligent hydraulic pulse jet vibration drilling device

A hydraulic pulse, intelligent technology, applied in the direction of drilling with vibration, vibration generating device, drilling with liquid/gas jet, etc., can solve the problem that the bottom-hole self-adjusting tool cannot be well adapted to the formation, etc., and optimize the oil well The effect of production operation, guaranteeing service life and improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

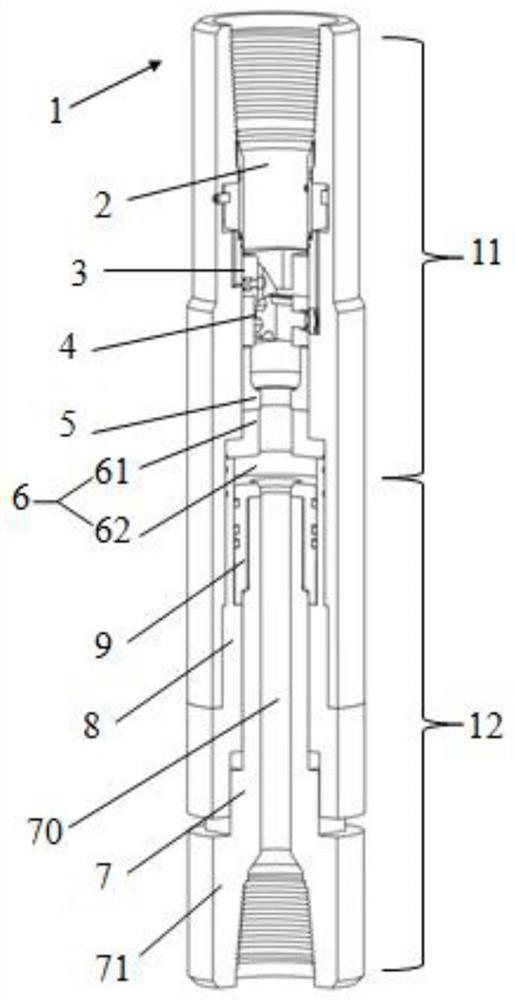

[0025] Embodiment 1 provides an intelligent hydraulic pulse jet vibration drilling device, and its structure will be described in detail below.

[0026] refer to figure 1 , the intelligent hydraulic pulse jet vibration drilling device includes a drilling tool body 1 .

[0027] The drilling tool body 1 is a hollow cylinder, and the top of the drilling tool body 1 is provided with an internal thread for connecting a drill pipe or a drill collar.

[0028] The middle part of the drilling tool body 1 is provided with a spacer ring device 6, and the spacer ring device 6 divides the drilling tool body 1 into an upper pulse jet part 11 and a lower vibration impact part 12.

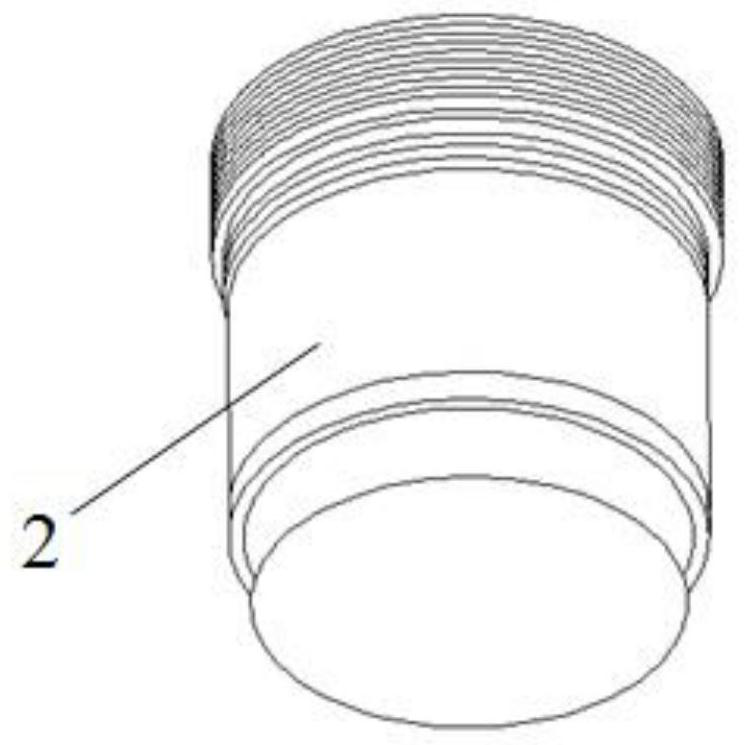

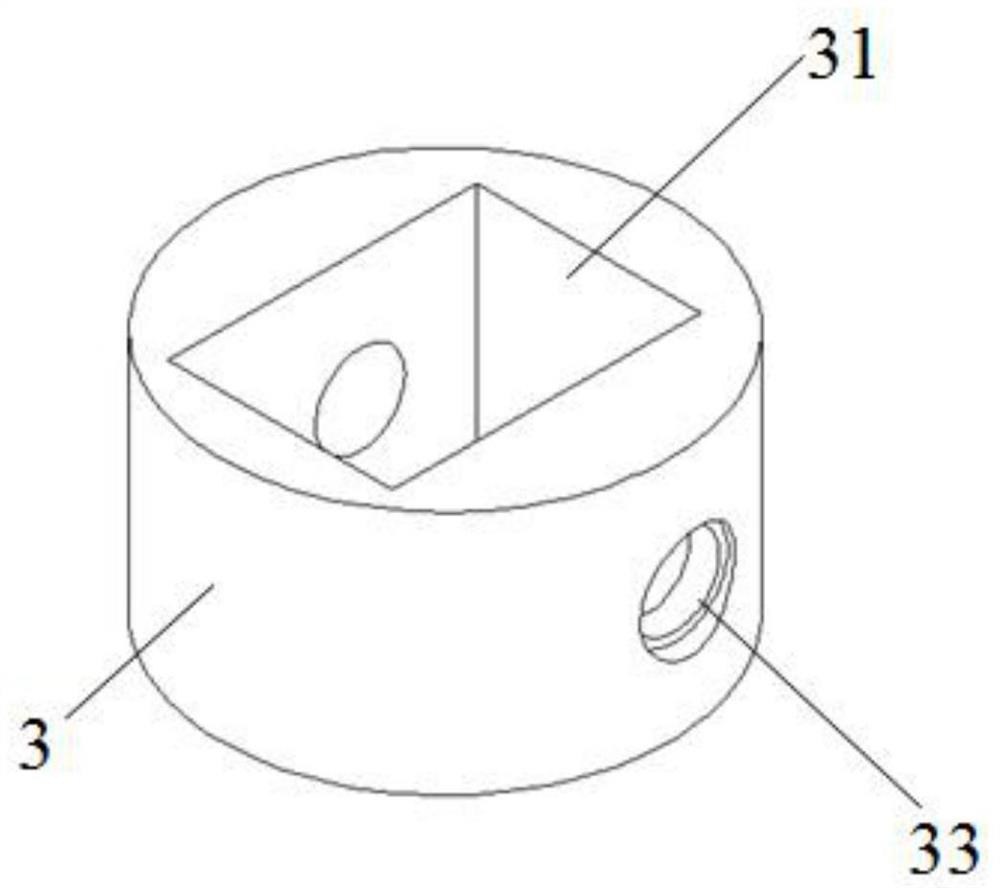

[0029] The pulse jet part 11 is sequentially provided with a sealing ring 2, a guide body 3, an impeller device 4 and a self-oscillating nozzle 5 from top to bottom, forming a pulse jet passage for circulating drilling fluid.

[0030] refer to figure 2 , the upper part of the sealing ring 2 is provided with ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com