A semi-dry airflow forming process for fiberboard

A technology of air forming and preparation process, which is applied in the directions of fiberboard, non-fiber pulp addition, fiber raw material processing, etc., can solve the problems of difficult to ensure product uniformity, difficult to control uniform constant value, and high fiber moisture content, and achieves improved dispersion. effect, adjust the breaking depth, improve the effect of fiber combing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

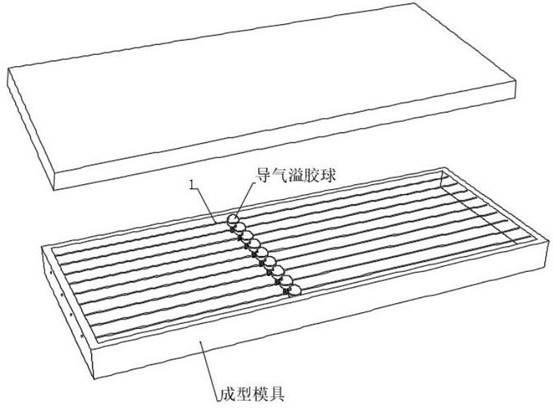

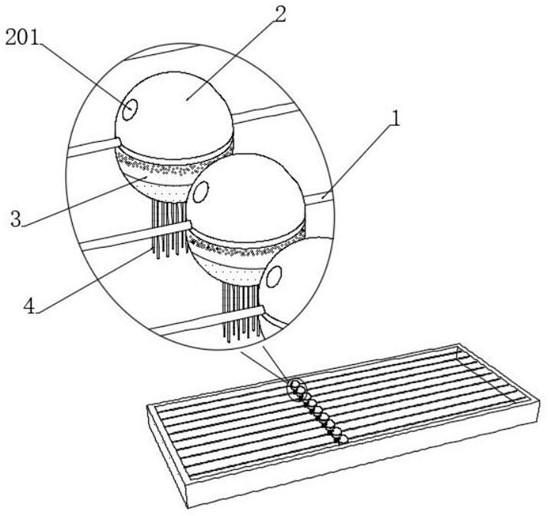

[0048] see Figure 1-2 , a semi-dry airflow forming preparation process of fiberboard, comprising the following steps:

[0049] S1. Fiber separation: steam the wood chip raw material, send it to a thermal mill to make wood fiber, and then gas-explode the wood fiber into fiber filaments after thermal grinding for standby;

[0050] S2. Slurry treatment: mix fiber filaments with additives and pure water to obtain fiber slurry. The additives in S2 include paraffin emulsion, waterproofing agent, preservative, and fire-resistant agent. The paraffin emulsion, waterproofing agent, and preservative , The mass ratio of the refractory agent is 3:0.5:0.3:0.2, the preservative is selected from pentachlorophenol, and the refractory agent is selected from MgNH4PO4 to improve the excellent performance of the finished product;

[0051] S3, semi-dry airflow group breaking treatment:

[0052] S31. Pour the fiber slurry into the mold for paving and smoothing, and set up a plurality of guide rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com