Combing cylinder with clothing elements

A technology of circular combs and components, applied in the direction of combing machines, deburring devices, textiles and papermaking, etc., can solve the problems of expensive, time-consuming, high precision, etc., and achieve the effect of simple installation and simple disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

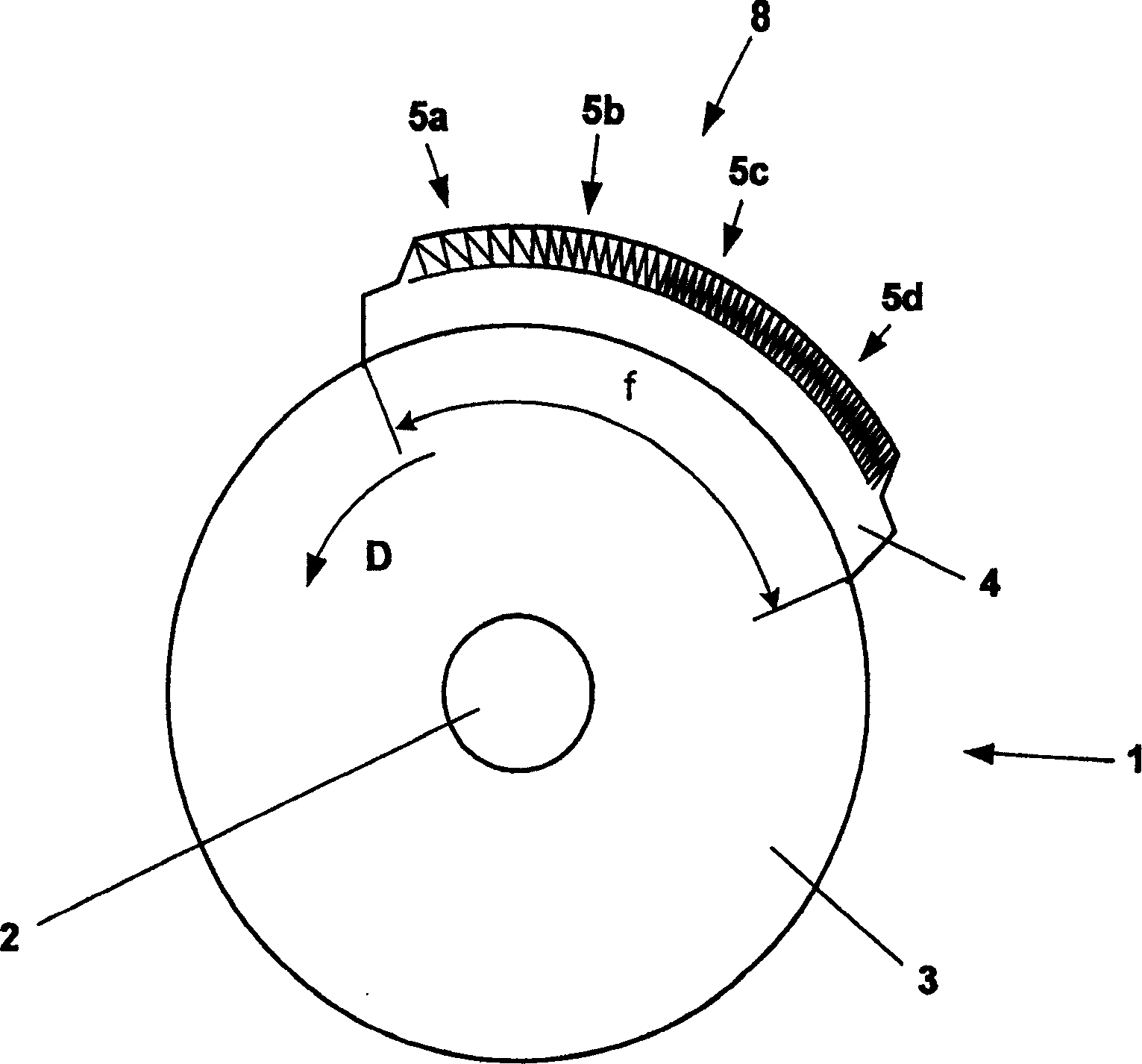

[0031] exist figure 1 In , a known type of circular comb 1 is shown, whereby a circular comb carrier 3 is fastened in a torsion-proof manner on the circular comb shaft 2 by fastening means, which are not shown in more detail. In this case the circular comb carrier 3 can be formed in one piece or in multiple pieces.

[0032] Fastened to the circular comb carrier 3 is a base body 4 which extends over a part of its circumference. Fastened to the base body 4 are different forms of sawtooth clothing rows 5a-5d, whereby the distance between the tooth tips of successive clothing segments can in any case be chosen to be smaller, for example. The toothed clothings 5 a to 5 d together form a comb segment 8 . In this case the sawtooth fitting is adhesively connected to the base body 4 or fastened by means of corresponding cutouts or notches, as already described in the introduction to the prior art.

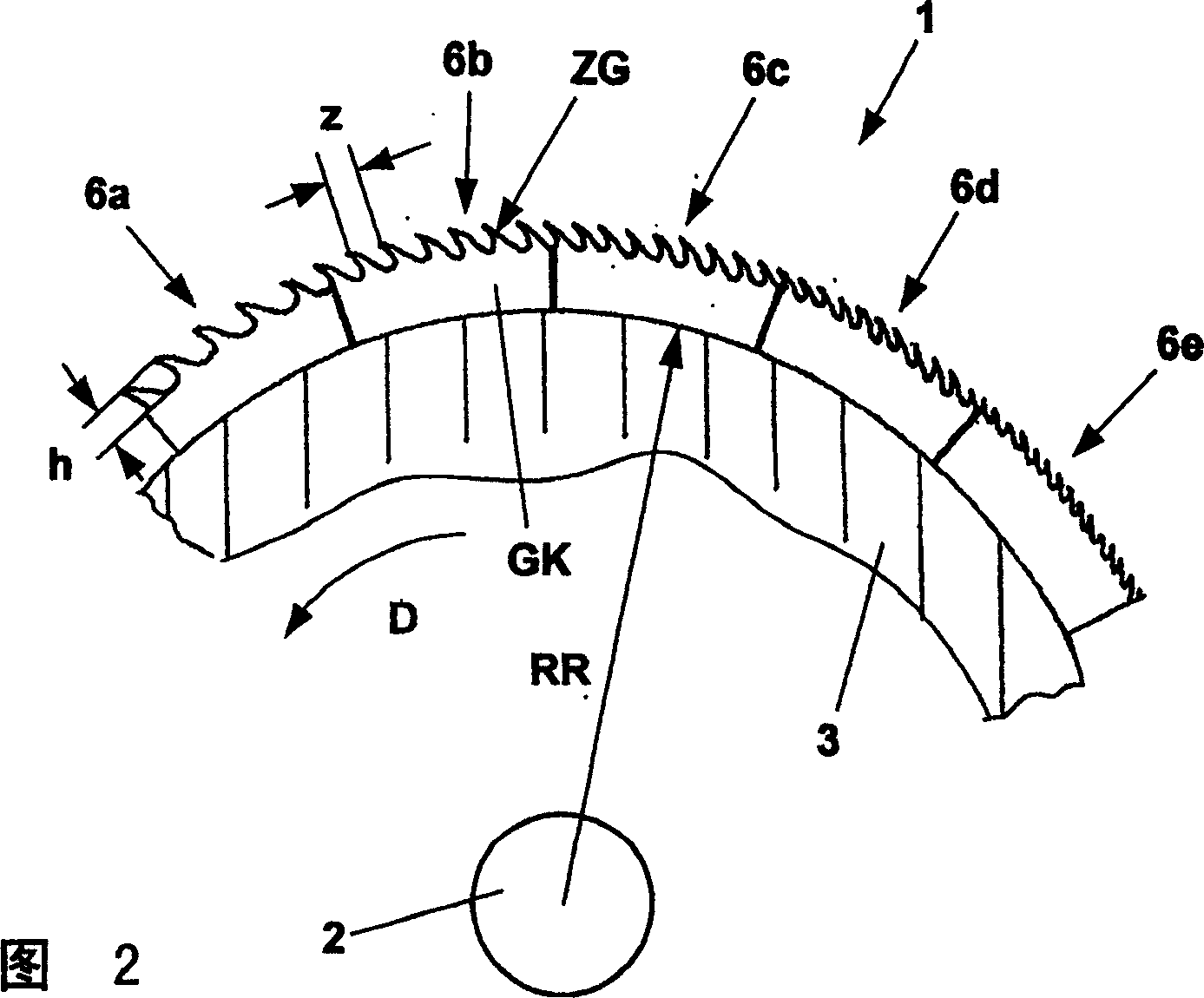

[0033] Figure 2 shows a basis for figure 1 A partial view of the combed segment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com